AUTODATA FAINS DIAGNOSTIC TROBLE CODE MODULE

- PostedPublished 12 June 2017

AUTODATA has launched a new diagnostic trouble code (DTC) module to save technicians time by easing the process of diagnosing faults.

The company says 5,000 unique (DTCs) are investigated by technicians every day, and that while these codes can be useful, they are sometimes difficult to understand.

Misinterpreting DTCs can lead to the time-consuming and expensive mistake of replacing components, only to find that the problem still exists and the code reader is still throwing the same DTC.

For example, DTC P1102 indicates a MAF sensor problem that could be caused by a simple air leak. It would not be solved by simply replacing this expensive component.

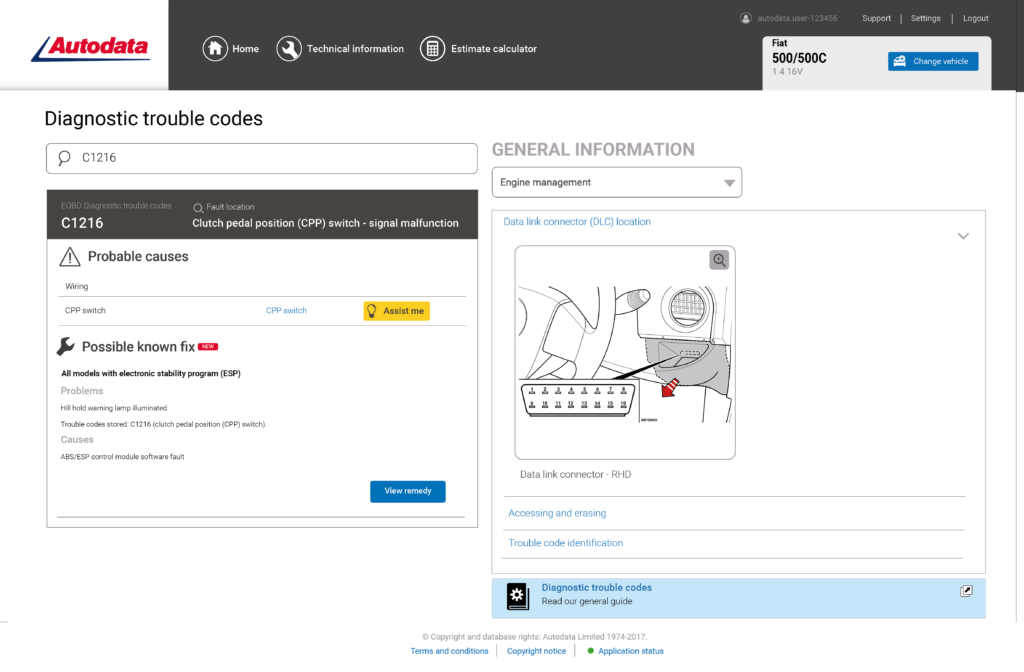

The new Autodata DTC module contains more than 2400 manufacturer-recommended technical fixes for common faults and speeds up repairs by immediately notifying the technician if the identified DTC relates to a common problem, then provides proven solutions.

DTCs do not always diagnose direct faults, instead providing systematic clues that require a combination of technical knowledge and investigation to solve.

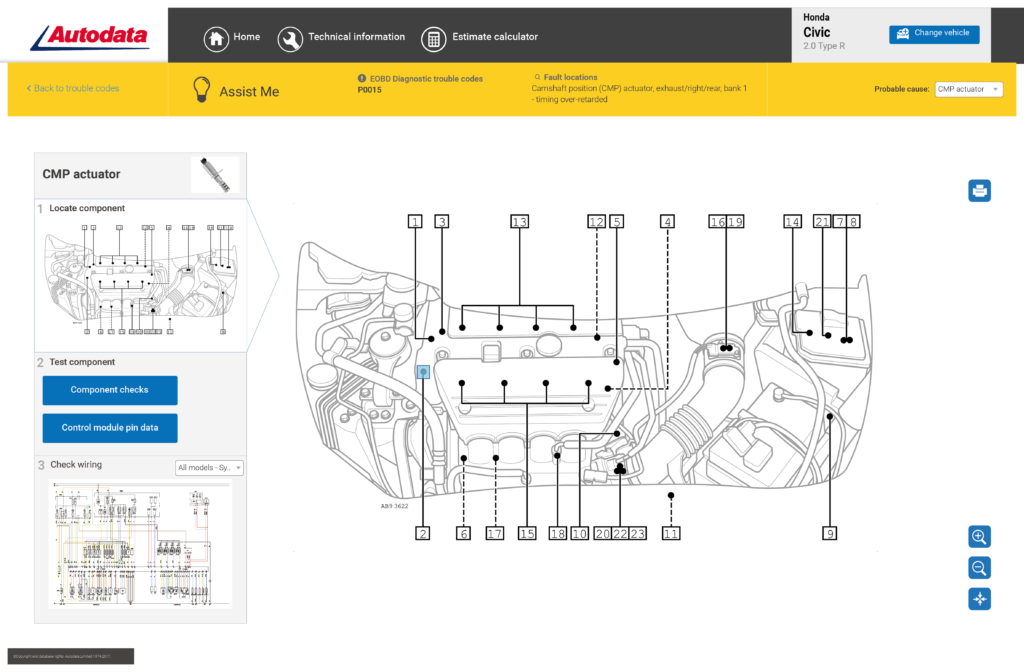

Another new feature of the Autodata DTC module is a diagnostic assistantce feature called Assist Me that provides a step-by-step diagnostics path for technicians to follow, based on the vehicle selected and DTC identified.

Assist Me uses real-life scenarios to guide the process while allowing experienced techs the freedom and flexibility to steer diagnostics.

More than 79,000 DTCs are available in the new Autodata DTC module, which users visit more 10,000 times every day.

The module provides technicians with everything from basic diagnostic information, such as accessing and erasing trouble codes, to more complex guidance, like identifying the systems associated with each diagnostic trouble code and informing technicians which faults are likely to have caused each code, and how to fix the faults.

Autodata chief strategy and innovation officer Max Lienard said a combination of accurate, reliable data and the right diagnostic tools can save repairers “valuable time and expense”.

“Our new DTC features enable workshops to further optimise efficiency,” he added.

“By spending less time carrying out diagnostics, technicians spend less time on each vehicle, therefore increasing the turnover of vehicles in workshops and potentially increasing the revenue of the business.”

The use of Autodata software, combined with more than 50 code readers on the market today, shows how far the repair industry has come in a relatively short time.

Less than two decades ago, each car manufacturer had a unique set of DTCs and methods of accessing them that now seem archaic, such as counting malfunction indicator lamp flashes or connecting a testing light or jump wire between two pins in the vehicle’s data link connector.

But no matter how advanced diagnostic equipment and software becomes, fault diagnosis remains a skill and a process of elimination, not to mention a major source of job satisfaction.

- CategoriesIn SightGlass

- TagsSightGlass News Issue 10