High-density battery tech innovations

- PostedPublished 17 June 2020

Cutting-edge energy storage paving the way for wider EV adoption

Researchers from the Queensland University of Technology (QUT) have devised an innovative new mechanical storage device.

Their proposal details a carbon nanostructure made from bundles of diamond nanothreads (DNTs). These ultra-thin one-dimensional carbon threads can be twisted or stretched, allowing them to store energy in a similar way to that of a clockwork mechanism or spring.

DNTs could be ideal for biomedical or wearable technologies, as they are safer and more stable than conventional chemical-based batteries.

Lithium-ion cells, for example, can suffer from leaks, performance degradation when cold, or even explode when excessively heated.

Research from QUT has also demonstrated that the energy density of DNTs is 1.76 megajoules per kilogram, claimed to be up to three times higher than a lithium-ion battery.

This could make them ideal for other applications, such as intelligent textiles or aerospace electronics.

Dr Haifei Zhan and his associates from the QUT Centre for Materials Science have so far modelled the storage and release capabilities of DNT bundles.

An experimental version is now being planned and Zhan says the team will first spend up to three years developing the control system for DNT bundles.

Developing alternatives to lithium-ion cells, which typically use liquid electrolytes, is high on the to-do list of many companies.

Liquid electrolytes tend to be toxic and flammable, for starters, which makes them ill-suited to some applications.

Solid-state batteries sidestep this issue by, as the name suggests, using solid electrolytes. These are demonstrably safer and can offer increased energy densities and better charging capability.

Unfortunately, the solid lithium metal anodes often used in solid-state batteries can suffer from dendritic crystal growth, which reduces performance and can cause short circuits.

However, researchers at South Korean manufacturer Samsung have proposed the use of a new silver-carbon (AG-C) composite layer for the anode of solid-state batteries.

The new anode, researched during a study on solid-state batteries, is claimed to grant a higher capacity, a longer charging cycle life and enhanced safety.

Samsung further claims that its five micrometre-thick Ag-C nanocomposite layer anode enabled its prototype to be 50 per cent smaller by volume than a conventional lithium-ion cell – making it ideal for use in electric vehicle applications.

Chinese automotive manufacturer BYD Auto is also among those demonstrating improved battery safety. It recently unveiled a new battery pack called ‘Blade’, which uses thin lithium-iron-phosphate cells instead of conventional cylindrical- or pouch-type lithium-ion cells.

While not as energy-dense as lithium-ion cells, lithium-iron-phosphate cells are more chemically stable and less prone to thermal issues.

In nail penetration tests, among others, a Blade battery did not even smoke after being damaged – and its surface temperature peaked at 60°C. In the same test, a damaged lithium-ion pack exceeded 482°F and burned violently.

The blade-like cells are also more space-efficient and contribute to the structural integrity of the thin aluminium pack itself, allowing for increased capacity that counters the energy density issues.

BYD has since announced that it will use the battery in its new flagship sedan, the Han EV, which has a claimed range of 605km.

While lithium-based cells are among the most energy-dense type, they remain expensive to manufacture – which drives the cost of any electric vehicle up.

Researchers from the Rensselaer Polytechnic Institute in New York state, however, have demonstrated a less expensive potassium-based metal battery that is said to perform almost as well as lithium-ion types.

Previously, as similarly experienced by Samsung, such cells would suffer from the formation of problematic crystalline dendrites on any solid potassium anode.

To overcome this, Professor Nikhil Koratkar and his team developed as self-healing strategy that involved rapidly charging and discharging the battery while it is not being used.

This cycling causes the battery temperature to rise, heating the protruding dendrites and smoothing them out.

It may ultimately be that a battery is developed which requires no rare, expensive or toxic materials at all.

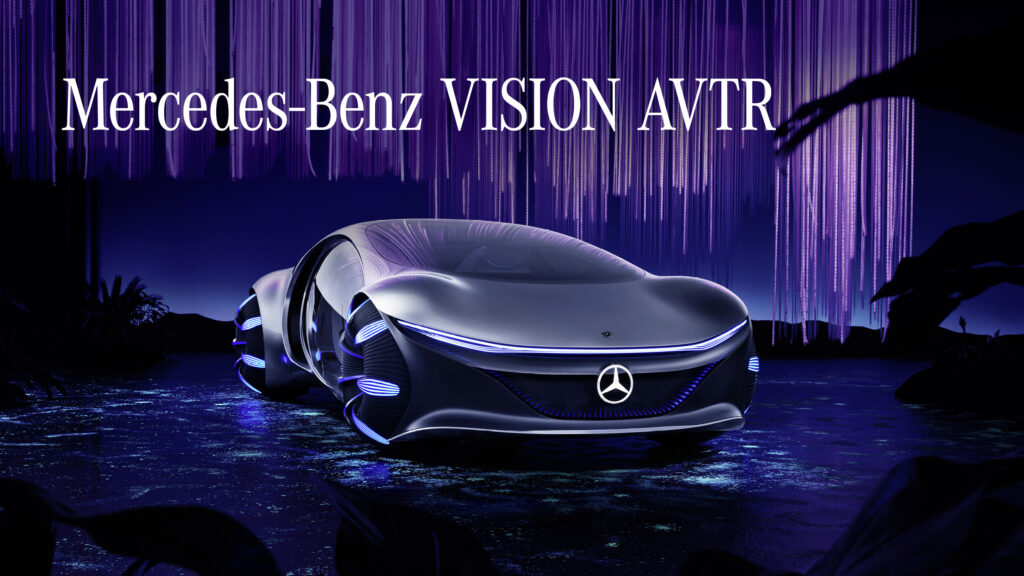

Mercedes-Benz is currently researching organic batteries, as a case in point, which will make use of graphene and compostable renewable materials while delivering high energy capacity and quick-charging potential.

This organic battery technology was previewed in the ‘VISION AVTR’ concept.

Professor Andreas Hintennach, head of battery cell research at Daimler, has however cautioned that commercially viable organic batteries are years – if not decades – from production.

OEMs flock to BorgWarner for EV coolant heater

BorgWarner is reporting strong demand for its range of advanced coolant heaters designed for electric and hybrid vehicles.

The US-based automotive supplier says its coolant heaters have been adopted for several high-volume vehicle programmes – thanks in part to the capabilities of its systems and the support and integration advice offered by its engineers.

Joe Fadool, president and general manager of BorgWarner emissions, thermal and turbo systems, said: “Our battery and cabin heater has become the technology of choice for some of the most important electric and hybrid vehicle manufacturers in Europe, North America and Asia.”

Coolant heaters are essential in electrified vehicles as there is no continuous source of waste heat to use for cabin heating or battery conditioning. In hybrids, where the engine may not be operating continually, coolant temperatures may need to be artificially raised.

The plate-type coolant heaters offered by BorgWarner are claimed to deliver high thermal power density and fast response times due to their low thermal mass – resulting in an effective, efficient and quick heating solution.

Power outputs range from 3kW to 9kW, while input voltages range from 250V to 800V; each heater also features robust electronics that can detect issues such as overheating and automatically switch off if required.

- CategoriesIn SightGlass

- TagsBatteries, battery, electric vehicles, SightGlass News Issue 20