Honda, GM team up for next-gen EVs

- PostedPublished 17 June 2020

GM to aid in design of all-electric Hondas

Your next Honda could be an electric car based on General Motors (GM) technology, thanks to a new collaboration announced in April.

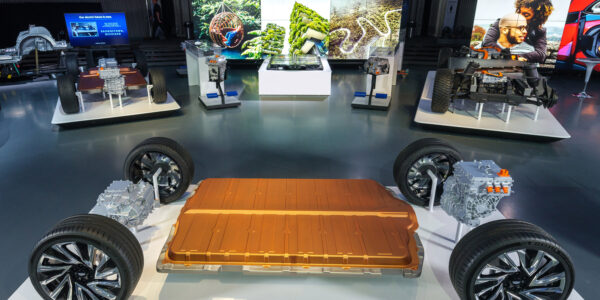

Honda will use GM’s third-generation flexible electric vehicle (EV) platform, which is powered by the Detroit-based multinational’s proprietary “Ultium” batteries, to underpin two all-new cars.

The exterior and interior will be designed solely by Honda, while the platform – dubbed “BEV3” – will also be reworked to deliver a driving experience in keeping with the Japanese brand’s dynamic character.

Each company will contribute its considerable development expertise to the project, but production of the new electric cars will take place at GM facilities in North America.

This is not some far-flung concept, either, as North American sales are expected to start in late 2023.

While this might seem an unexpected development, there is much history of collaboration between GM and Honda in the field of electrification.

In 2017, both invested $85 million (then approximately $A113 million) in a large-scale hydrogen fuel cell production project – and the companies have also teamed up on battery and electric vehicle development projects.

“This collaboration will put together the strength of both companies, while combined scale and manufacturing efficiencies will ultimately provide greater value to customers,” said Rick Schostek, executive vice president of Honda America. “This expanded partnership will unlock economies of scale to accelerate our electrification roadmap and advance our industry-leading efforts to reduce greenhouse gas emissions.”

No specific technical details about the upcoming zero-emissions Hondas have been announced yet, but each will receive GM’s OnStar safety and security services – features which will be integrated into Honda’s own HondaLink car control app.

However, GM has previously revealed some details about the capabilities of its modular EV platform.

Unsurprisingly, the flexible “skateboard”-type design allows for the use of either front-, rear- or all-wheel-drive configurations. A range of battery and charging systems are also said to be available, allowing the platform to be best tailored to suit its application or market.

Honda has additionally expressed an interest in making GM’s hands-free advanced driver assistance technology available in its cars, which may serve to attract customers who might otherwise only consider alternatives such as Autopilot-equipped Teslas.

The companies are reportedly discussing the possibility of expanding the partnership, which could result in more technology and platforms being exchanged between the brands in the future.

Inside Ultium

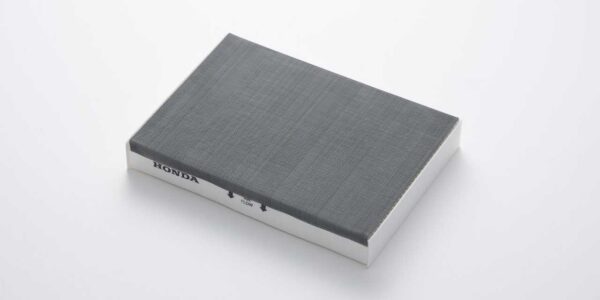

GM’S proprietary Ultium batteries are a crucial component of both the company’s plans and its BEV3 platform. Like the platform itself, Ultium batteries are easily configured to suit myriad applications – allowing GM to use them in a wide array of vehicles, which should help cut costs.

This advantage is granted through the use of unique large pouch-style cells in the modules of Ultium battery packs, instead of cylindrical cells. The pouches are light, space-efficient and less complicated to install – and can be stacked vertically or horizontally in a module, making it easier to design packs for different applications.

A management system is built into each module, which alone reduces the pack wiring by 80 per cent compared to previous designs. The pouches also use 70 per cent less cobalt than competitor batteries, among other innovations, reducing supply issues and costs.

GM has confirmed pack capacities from 50kWh to 200kWh, the latter of which could deliver a range of up to 644km. Ultra-rapid 200kW fast charging is also mooted, with up to 350kW for variants destined for truck platforms. Performance should be unsurprisingly swift, too; an all-wheel-drive performance derivative of the BEV3 is reputed to have a 0-100km/h time of around three seconds.

Production in Lordstown

A new factory is being built in Lordstown, Ohio, to mass-produce cells for Ultium batteries.

The cutting-edge factory, the ground for which was broken in May, is the result of $2.3 billion ($A3.4 billion) joint venture between GM and LG Chem, which has been aiding GM in developing advanced and low-cost battery technologies.

“Our joint venture with the No. 1 American automaker will further prepare us for the anticipated growth of the North American EV market while giving us insights into the broader EV ecosystem,” said LG Chem Vice Chairman & CEO Hak-Cheol Shin.

- CategoriesIn SightGlass

- Tagselectric vehicles, General Motors, GM, Honda, SightGlass News Issue 20