HYBRID POWER ELECTRONICS: WHAT ARE THEY?

- PostedPublished 5 March 2017

IN HYBRID and electric vehicles, there are high-voltage components required beyond the battery pack. In this article, we will explore the inverter.

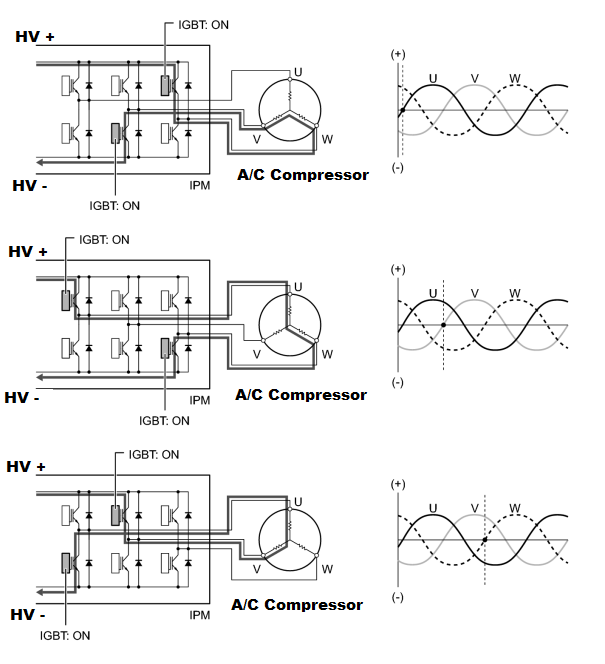

The inverter acts as a motor controller, in this case it supplies the alternating current (AC) power to the high-voltage air conditioning compressor (Fig.1).

A computerised device, the inverter can switch direct current (DC) volts rapidly to produce an artificial AC power supply to the stator, then the stators (electromagnets) switch polarity from north to south and create a rotating magnetic field.

Powering the air conditioning compressor is the high voltage battery pack in the 200 to 400 DC voltage range.

The inverter has two jobs: Running high-powered, high voltage motors using AC power it converted from DC and secondly, controlling the speed.

For motors connected to a wheel or crankshaft, the inverter’s job is also taking three-phase AC power and converting it into DC for recharging the high-voltage (HV) battery pack. In this way the motor can also be a generator.

Toyota calls these motor/generator (M/G). The air conditioning compressor is only a motor, so it has a simpler life.

Inside an inverter is a circuit board along with diodes and power transistors.

Every electric HV motor that runs on AC power requires its own inverter.

The inverter is the controller for the AC-powered electric motor and not only supplies the AC power but also controls that power so the motor can operate at any speed within its operating range, including the direction of rotation, forward or reverse.

Again, the air conditioning compressor has a simpler life, only needing to go in one direction.

The inverter starts with high voltage DC power and brings that DC power to a set of insulated gate bipolar transistors “IGBT”. A big word for a simple idea.

These high-powered switches, of which there are six in each inverter, work alongside six diodes.

An ECU switches the IGBTs on and off (Fig. 2) and duty-cycles them as needed. The system is not unlike the six diodes in a conventional alternator, but with the added IGBTs at each diode.

During motor application the IGBTs are switched on and off rapidly and in the process make a digital AC wave form. The IGBTs turn on and off up to 10,000 time per second.

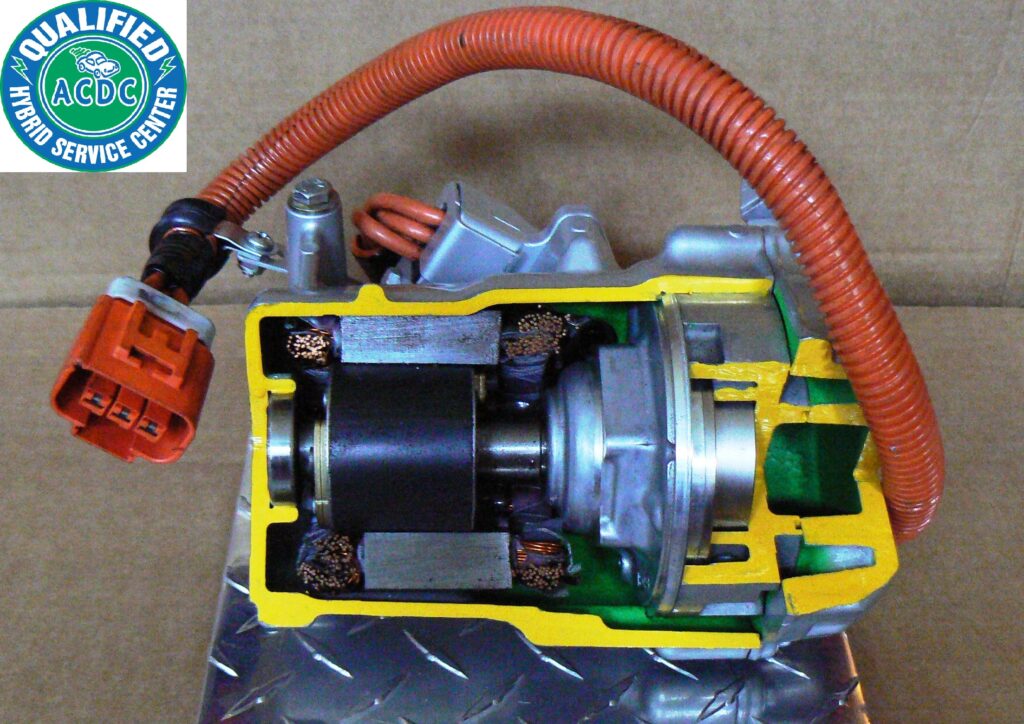

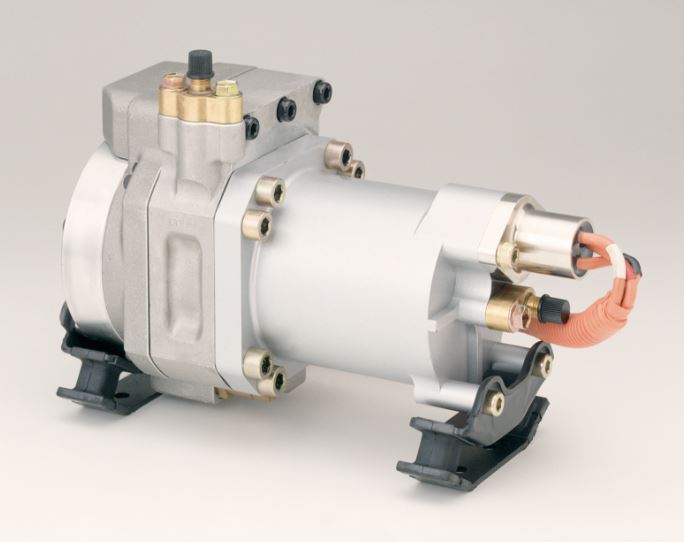

The first HV electric air conditioning compressors had an external inverter that supplied the three-phase power. It is possible to tell which ones used this system from the number of orange cables going into the compressor.

Fig. 3 has three orange cables and Fig. 4 has only two.

Inverters of this nature are expensive and heat sensitive. Honda was able to get away with air cooling for all of their hybrid air conditioning parts but everyone else in the market used liquid cooling to remove heat.

In model year 2014 Honda switched to a pure-electric compressor and used the cold inlet at the compressor to cool the IGBT by locating the inverter inside the compressor.

This was not a new idea, as Toyota did this first in 2006.

Understanding what these parts do and the service required will help you do your job as more hybrids and plug-ins are sold and need service.

- CategoriesIn SightGlass

- TagsSightGlass News Issue 9