Nissan charges ahead with new EVs, tech

- PostedPublished 21 September 2021

In 1996, Nissan unveiled an all-electric version of its Prairie people-mover. It was the result of decades of research and the first electric car with a lithium-ion battery – a high-capacity, low-weight solution that would become the standard solution for myriad electric vehicles (EVs).

Nissan subsequently capitalised on its experience with the launch of the all-electric Leaf and, as sustainable motoring becomes even more important, it continues to expand its zero-emission line-up.

The latest addition to its line-up is the e-NV200 XL Volita van, which is a high-capacity version of the existing e-NV200. The new European-market urban delivery van offers up to eight cubic metres of storage space, which is 90.5 per cent more than the standard e-NV200.

As with the e-NV200 on which it is based, the XL Volita uses the Leaf powertrain and a 40kWh battery pack. It’s claimed to have a 580kg payload, a 200km range and a top speed of 123km/h. Nissan also claims a rapid charge time of approximately 50 minutes to 80 per cent, helping minimise downtime.

Nissan’s electric vehicles are not only being adopted by individuals and business users. In Japan, as a case in point, the Tokyo Fire Department has just accepted its first all-electric Nissan EV Ambulance. It’s a conversion based on the NV400 panel van and is aimed at expanding the range of eco-friendly vehicles that are available to communities, helping bring emissions down further.

Polymer battery tech

However, electric vehicles – and battery-based storage solutions – often command a premium. Fortunately, ever-developing battery technologies and production facilities are reducing costs and make zero-emissions technology more accessible.

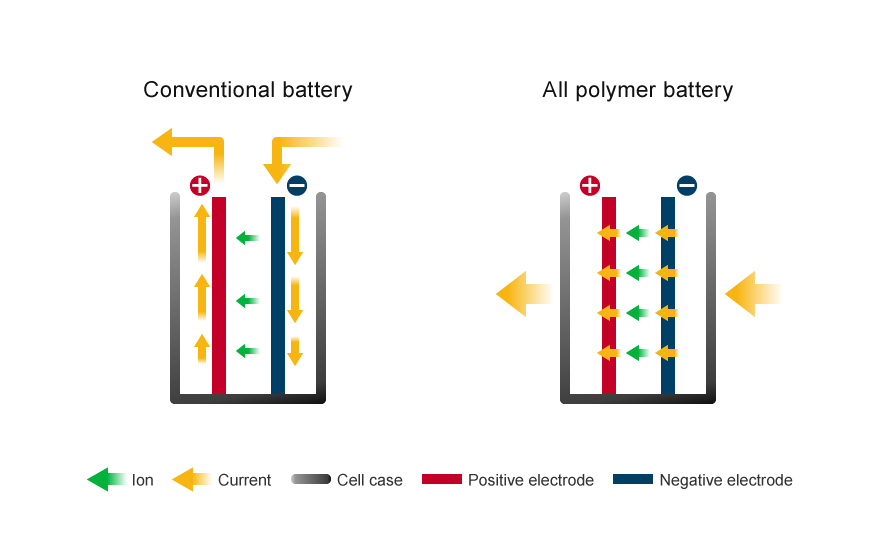

Commonly used lithium-ion battery cells, for example, could be superseded by all-polymer lithium-ion cells; these do away with the liquid electrolyte of lithium-ion cells and instead use highly conductive gel polymers that contain an electrolytic solution.

A range of benefits is cited, including improved safety, increased charging capacity, a simplified structure and lower costs.

Nissan has recently licensed such technology to the Japanese APB Corporation, which intends to develop and manufacture all-polymer cells for non-automotive fields.

For instance, large-scale production of the more affordable cells could reduce the cost of stationary batteries – making renewable or low-cost energy storage solutions more accessible.

Sleeping like a baby

Nissan has even started casting its eye over more obscure facets of zero-emissions life. If you’re a parent, you may well be familiar with the concept of a “dream drive” – where you take your infant for a cruise around the block in the hope that the motion of the car and noise of the engine will send them to sleep.

Research commissioned by Nissan identified that the sound frequencies of an engine are a major contributor to children nodding off, posing a potential problem for EV owners.

Nissan subsequently, in collaboration with sound designer and sleep coach Tom Middleton, developed three five-minute audio tracks that contain all the noises required to induce a trip to the land of nod.

The new lullabies are available on platforms such as Spotify and Apple Music, allowing for easy playback at home or in your car.

- CategoriesIn SightGlass

- Tagselectric vehicles, Nissan, SightGlass News Issue 20