NZ Automotive AC field survey, summer 2014-2015: Part 2

- PostedPublished 18 December 2015

The survey

The survey of air conditioning faults in 667 motor vehicles, including cars, trucks, tractors and heavy equipment was conducted from 1 December 2014 to 31 March 2015 and includes actual repairs and evaluations carried out by CoolCar air conditioning Centre, Hamilton (more background can be found in the September 2015 edition of SightGlass News).

The fleet

A comparison can be made with the vehicles surveyed in the Mobile Air Conditioning Society (MACS) 2013 field survey. MACS is a US-based organisation serving the automotive air conditioning service industry, with close ties to VASA.

Due to our timeframes, our data also includes vehicles manufactured in 2014 and 2015. Those vehicles that may have been subject to a new vehicle warranty at the time they were in the workshop are shown in a separate category (2012-2015).

The general findings

| 279 | Refrigerant fault only |

| 156 | Refrigerant fault and non-refrigerant-related fault |

| 227 | Non-refrigerant-related fault found only |

| 5 | No fault found |

| 667 | Total |

1931-1989

The MACS data included more vehicles in the oldest age group. The oldest vehicle in our group is from 1976, reflecting the later time air-conditioned vehicles appeared on the NZ market.

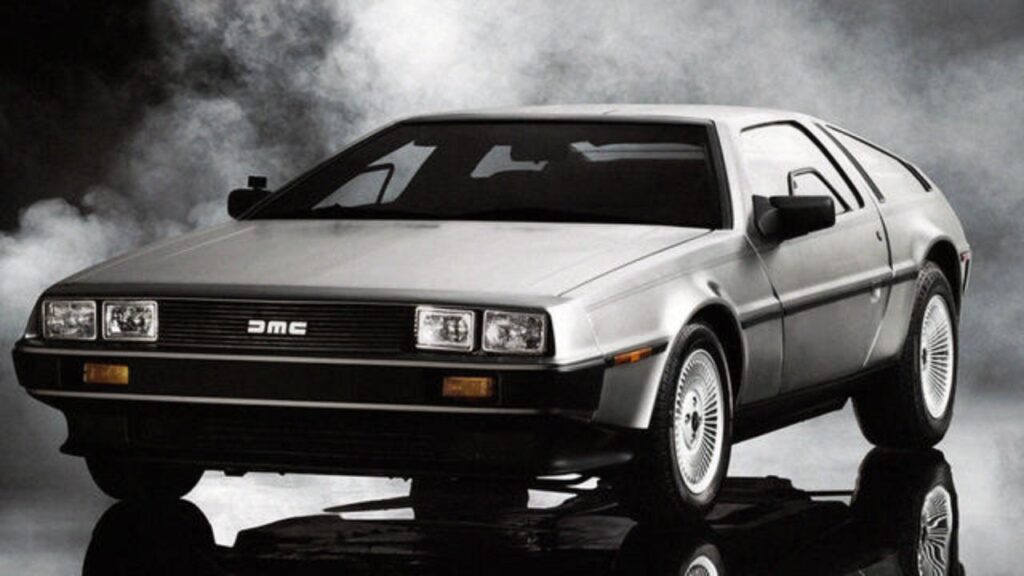

The most interesting vehicle in this group was a 1981 De Lorean DMC, built for the US market.

Within this group of nine vehicles, eight had low refrigerant. Leaks could be identified in seven of these cars for repair. The ninth vehicle had refrigerant leaks attended to four months previously at CoolCar Hamilton and was fully operational when inspected. The issue was possibly operator error.

So refrigerant leaks were the predominant cause of system failure in this group and demonstrable leaks could be found in all but one vehicle, the De Lorean, to which UV dye was added.

Four vehicles also had other faults affecting air conditioning operation and performance. One had a seized compressor secondary to low refrigerant, the De Lorean had an electrical fault to the heater and air conditioning and a Nissan Skyline had a blend door actuator fault and a faulty compressor clutch coil.

Quite a few in this group were still running on R12 and most vehicles that had been retrofitted to R134a were leaking significantly from compressor seals.

1990-1994

This vehicle grouping also showed a clear predominance of refrigerant leaks as the main cause of poor performance.

46 of 51 vehicles had a refrigerant-related issue and seven vehicles also had another fault. UV dye was found, used or recommended in 12 cases as an aid to leak detection.

Five vehicles had a non-refrigerant-related problem (one vehicle had been re-gassed elsewhere but there was no drive to the compressor due to a badly worn drive belt and no leaks were demonstrated).

One R12 vehicle – leaking from the discharge fitting at the condenser – had been re-gassed with contaminated refrigerant.

Excessive static and operating pressures were not really observed in this or the earlier group except in a 1992 Porche 968, with a lack of functioning cooling fans leading to excess AC system temperatures and pressures because it was unable to dissipate heat as required.

1995-2011

This vehicle grouping showed a clear change in the predominance of non-refrigerant-related problems causing or adding to poor performance.

348 of 563 vehicles had a refrigerant-related fault, while 137 also had another fault and nine vehicles had contaminated refrigerant.

212 vehicles (38%) had a purely non-refrigerant-related problem that lead them to CoolCar Hamilton.

An additional three vehicles had no faults found and one had the AC switched off, however all three may have had an intermittent fault that was not observed during testing.

UV dye was found, used or recommended in 101 cases as an aid to leak detection.

2012-2015

In this group, 25 of 34 vehicles had a refrigerant-related fault. Five of these vehicles also had a non-refrigerant-related fault and nine vehicles had a solely non-refrigerant-related problem.

UV dye as a diagnostic tool

When UV dye was used as an aid to leak detection/elimination, customers followed our leak checking policy 75 per cent of the time. In cases where cars had previously been re-gassed, if there was any noise in the compressor or a direct drive compressor, it is CoolCar Hamilton practice to add UV dye and refrigerant and run the vehicle in the workshop until the leaks are found, otherwise customers are advised to return to have their vehicle AC rechecked in two weeks (earlier if they notice a loss of cooling performance) and again following another two weeks if no leaks were found. Leaks were subsequently found in the majority of cases.

Before UV dye and refrigerant are added to a vehicle, customers are walked through the likely repair and servicing scenarios to give them an idea of repair costs and in a small number of cases, customers elect not to take any further action (12 did this during our survey).

By Catherine Tocker, VASA Director

NOTE: This article is written in the context of the New Zealand market and regulations. Australian workshops must refer to the Australian Automotive Air Conditioning Code of Practice for local guidance on the use of UV dye in diagnosing system leaks.

- CategoriesIn SightGlass

- TagsNew Zealand, SightGlass News Issue 4, Workshop