Ultra-white paint cuts cooling challenges

- PostedPublished 20 September 2021

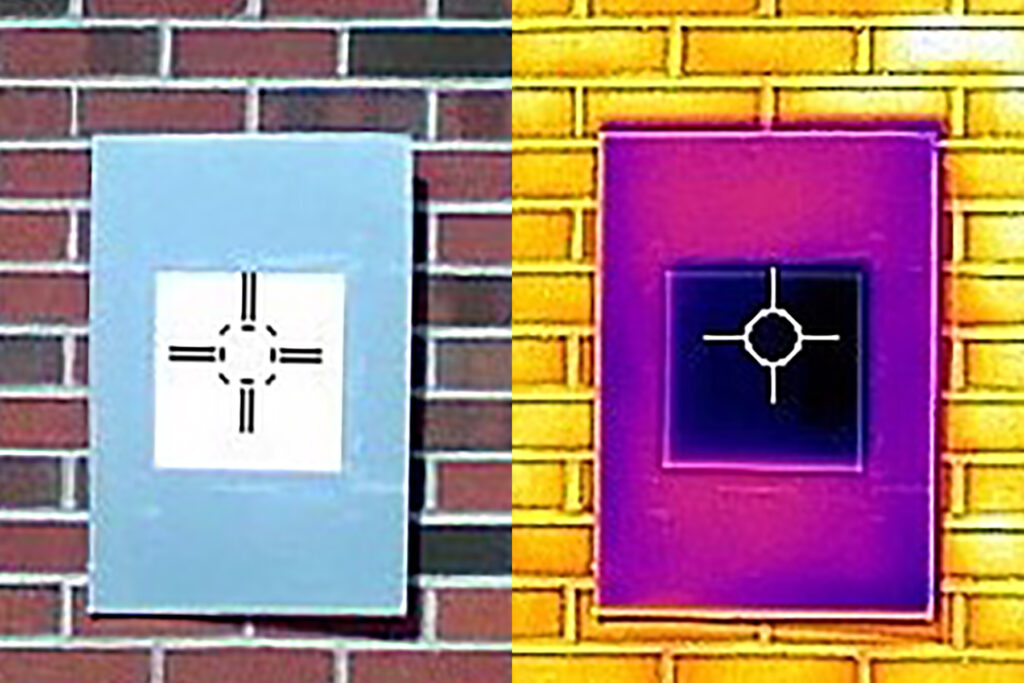

Engineers at Purdue University in the United States have quickly improved the performance of a white paint that can passively cool surfaces.

The team behind the ultra-white paint has revealed an improved formula that can keep surfaces cooler than the version demonstrated last October.

A new formulation is said to reflect up to 98.1 per cent of sunlight and cool surfaces more than 4.5°C below ambient in strong daytime sunlight.

At night, the infrared emissivity of the paint can reduce surface temperate by 11°C.

This represents a substantial performance leap over how well initial iterations of the specially formulated heat-rejecting paint, which radiates heat in the form of infrared, and was originally reported to keep surfaces more than 1.7°C cooler than their surroundings in daytime conditions and able to reflect 95.5 per cent of sunlight.

In any case, the new formula outstrips commercial alternatives that only reflect up to 90 per cent of sunlight while offering no passive cooling capabilities.

“If you were to use this paint to cover a roof area of about 1000 square feet 992.9 square metres), we estimate that you could get a cooling power of 10 kilowatts,” said Xiulin Ruan, a Purdue professor of mechanical engineering.

“That’s more powerful than the central air conditioners used by most houses.”

The white radiative cooling paint, which features barium sulphate – a chemical compound used to make cosmetics and paper white – could subsequently be used to coat buildings and reduce air-conditioning demands.

Researchers at the American university have also demonstrated that the reputedly easily handled paint should cope with outdoor conditions, while production is reportedly possible in commercial facilities.

It follows that the technology should have applications in the transport refrigeration or even automotive industries as tougher energy efficiency and emissions targets leave no stone unturned in the search for methods of reducing thermal loads.

Iceman ice machines using R1234yf

Japanese ice production and transport specialist Iceman Corporation has announced it will adopt R1234yf refrigerant for its plate ice machines.

The more environmentally friendly refrigerant will take the place of R404A, which has a high global warming potential (GWP).

“The gradual phase-down of HFC [hydrofluorocarbon] refrigerants due to Kigali makes it critical to transition away from high GWP existing refrigerants to the next generation of low GWP solutions,” said Iceman president Tomoaki Akiyama.

He added that the refrigerant delivers a GWP reduction of more than 99 per cent, without any performance impact, making it an effective yet far more environmentally friendly solution.

- CategoriesIn SightGlass

- Tagsair-conditioning, cooling, paint, SightGlass News 24