WHY THERMAL EFFICIENCY IS THE NEW AUTOMOTIVE BATTLEGROUND

- PostedPublished 1 June 2017

THE past two editions of SightGlass News looked into the future of refrigerants, their growing role in automotive thermal management and how these will combine with driveline electrification to impact our industry.

It is now time to explore the quest for thermal efficiency that links these topics together and will be increasingly considered in the design of almost every component that goes into a vehicle.

Regardless of which alternative fuel technologies are vying to eventually replace the internal combustion engine, maximising thermal efficiency will be a key engineering goal, as it is intrinsically linked with energy efficiency.

Engine designers have identified, and are constantly developing, new ways of making combustion cycles more efficient.

With most internal combustion engines averaging around 30 per cent efficiency – that is less than a third of the potential energy in fuel reaching the crankshaft –there are serious gains to be made.

Techniques to improve the situation include expanding on known efficiency-boosting methods, learning from motorsport, using cutting-edge nanotechnology or harvesting heat energy that would otherwise be wasted

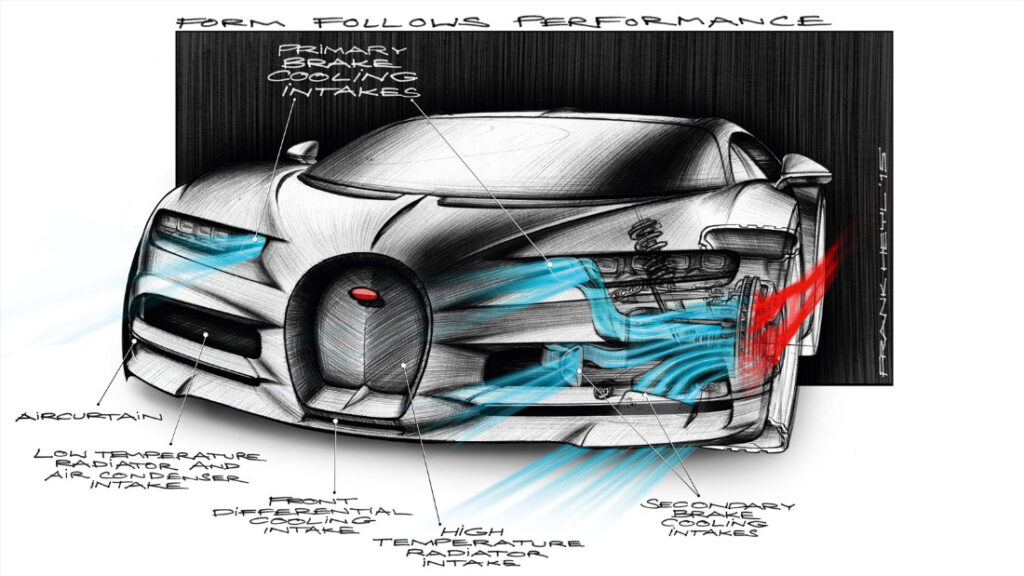

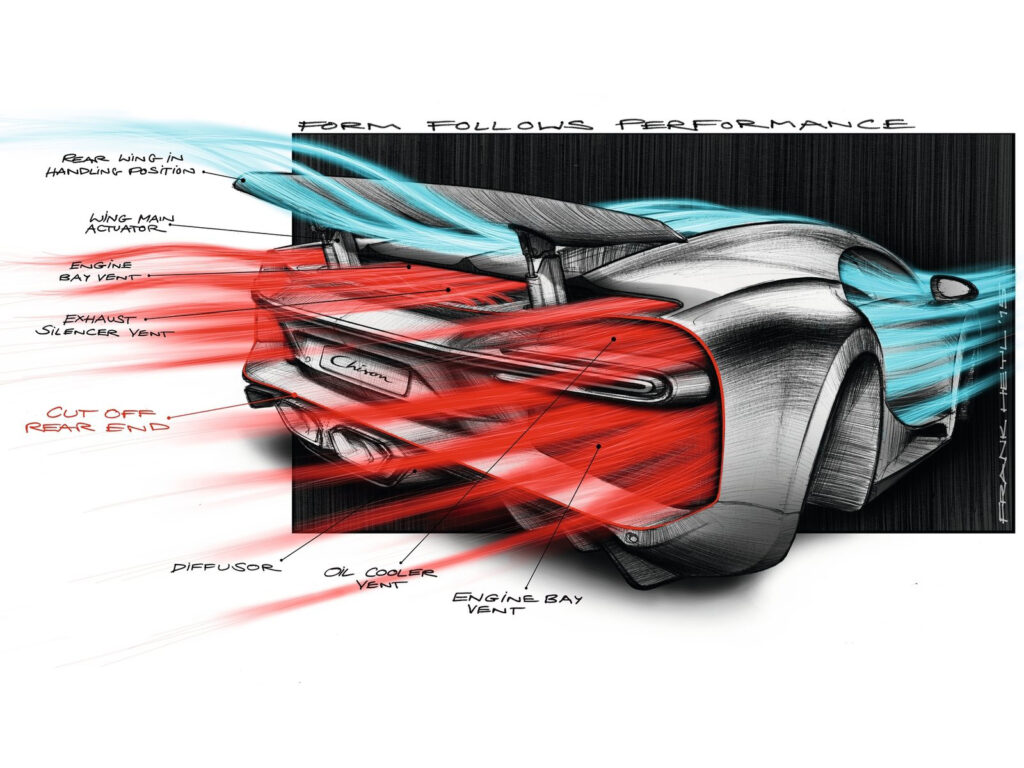

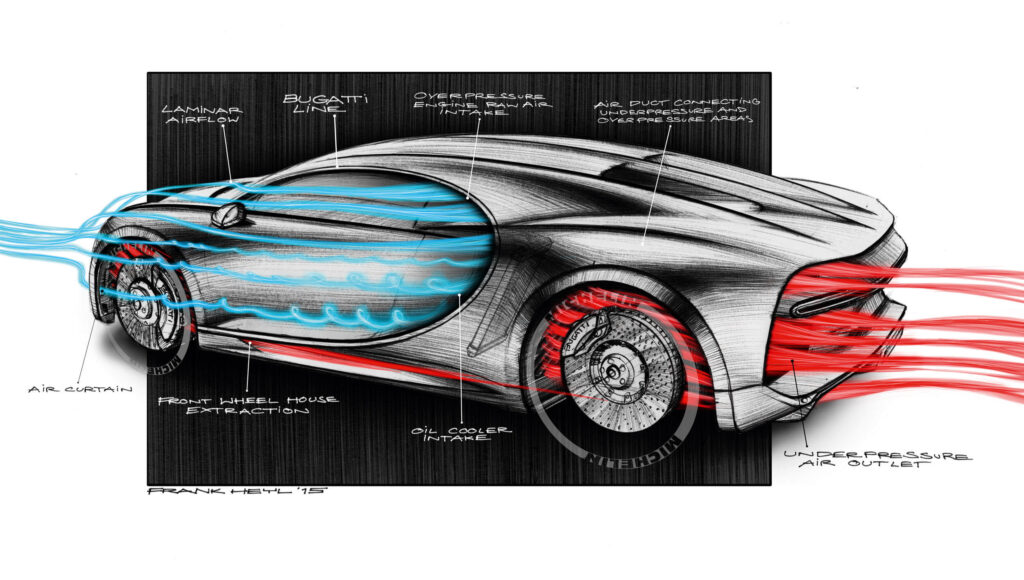

So what does the Bugatti Chiron pictured above have to do with all this? Its 1103kW engine generates more than 2239kW of heat rejection for the 10 heat exchangers and three coolant pumps to deal with, circulating its entire 37-litre coolant capacity every three seconds.

Shape of things to come

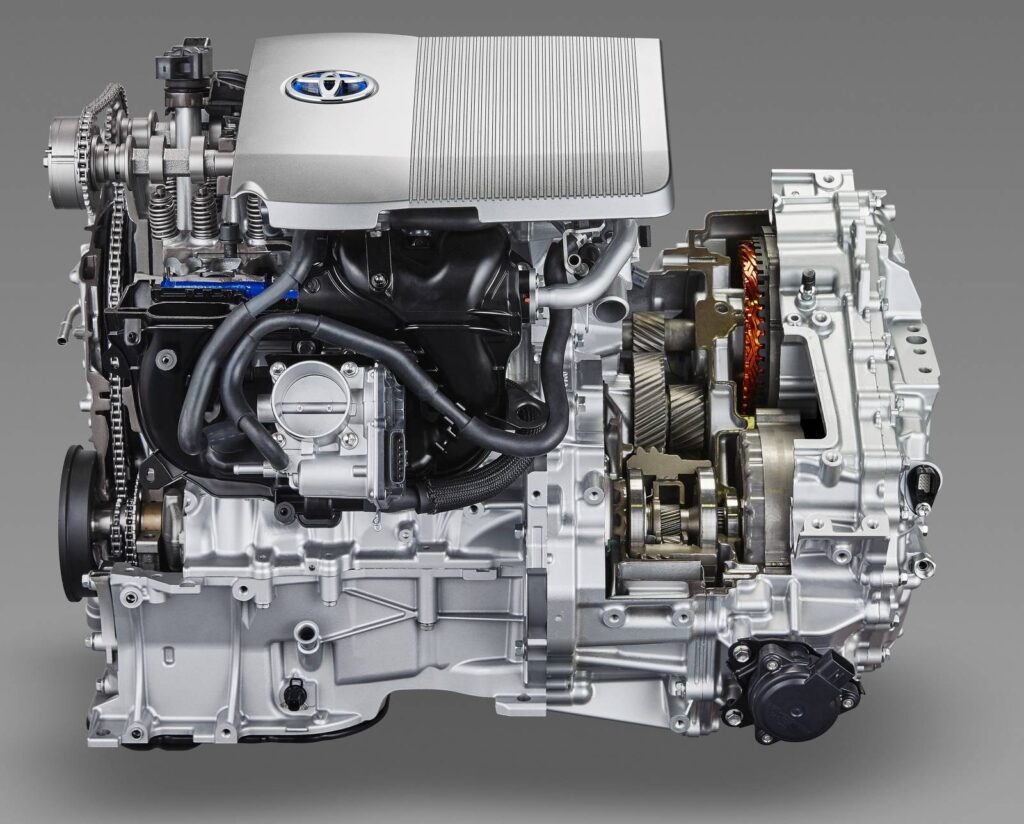

The bread and butter of Toyota’s business model is not ground-breaking innovation, preferring to slowly introducing tweaks to maximise the simplicity, reliability and profitability of its best-selling models.

But the 1.8-litre petrol engine in the fourth-generation Prius hybrid achieves 40 per cent thermal efficiency. That’s a big step-change.

It is also closing in on the latest F1 race engines that are at least 45 per cent efficient, with teams now setting their sights on 50 per cent. More on that later.

Toyota says the Prius engine’s thermal efficiency gains come from the use of large-volume exhaust gas recirculation, better gasflow inside the combustion chamber, coolant galleries designed to optimise internal engine temperature, and reduced friction of piston skirts and rotating parts, helped by low-viscosity oil fed via a low-friction pump, in turn easing movement of sliding engine components.

Also used are active grille shutters, which adjust airflow over the heat exchangers depending on ambient temperatures and heat load, while heat from the exhaust is fed into the coolant, the flow of which can be precisely controlled around the head and block to help reach operating temperature more quickly. Cabin heating also benefits from these measures.

VW Group is also pursuing efficiency gains through thermal management using similar measures to Toyota, plus cylinder heads and crankcases with independent cooling circuits, on-demand water pumps and actuators that distribute coolant, enabling engine heat to rapidly warm up the transmission fluid and help reduce frictional losses.

It also means coolant in the block is only circulated in high ambients or under high engine load. Similarly, the engine oil cooler is bypassed unless required.

Coolant circulating around the head is used for cabin heating and for the cooled exhaust gas recirculation system.

These cars are on Australasian roads now and represent just the beginning of significant efficiency gains that have so far eluded engine manufacturers.

In Europe and other key markets including the United States, stringent emissions and corporate average fuel economy limits are being introduced faster than the market is transitioning to alternative fuels and electrification.

A global trend toward SUVs that are heavier and less aerodynamic than passenger cars is compounding the issue, as is the growing anti-diesel sentiment.

This means manufacturers are making large investments in combustion engine technologies, to avoid hefty fines.

Petrol engines are intrinsically less thermally efficient than diesel so engineers are working on closing the gap.

Thermal harvesting

The more sources from which electricity can be generated reduces the load on – or even the need for – alternators that cause engine drag while delivering obvious benefits for extending the range of electrified drivetrains.

Regenerative braking, originally developed for electric and hybrid cars to top up their batteries under deceleration rather than wasting kinetic energy as heat through conventional discs and drums, is well-known and now commonly adopted on non-hybrids to reduce alternator load.

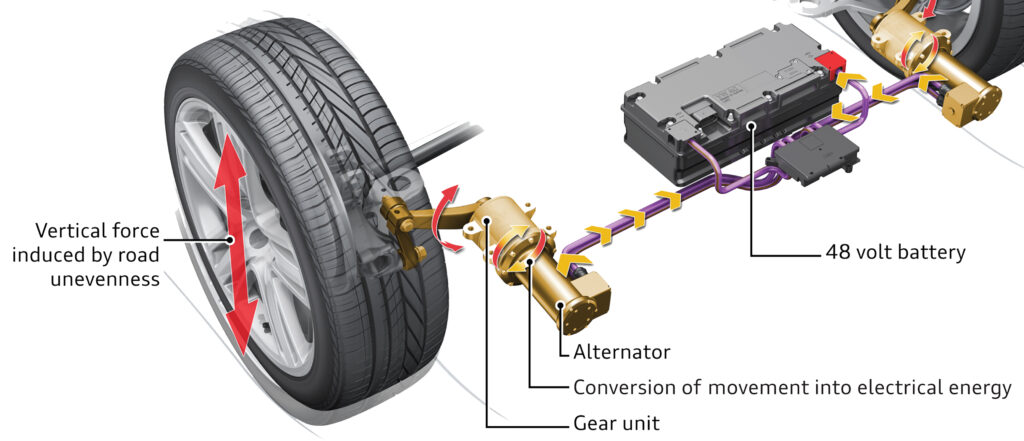

The next stage is harnessing the energy of suspension movement, again typically lost as heat, to create electricity.

Systems based on both conventional telescopic shock absorbers and rotary dampers are under development.

Early prototypes fitted to all four wheels of a large off-road vehicle driving on rough terrain generated more electricity than a conventional alternator.

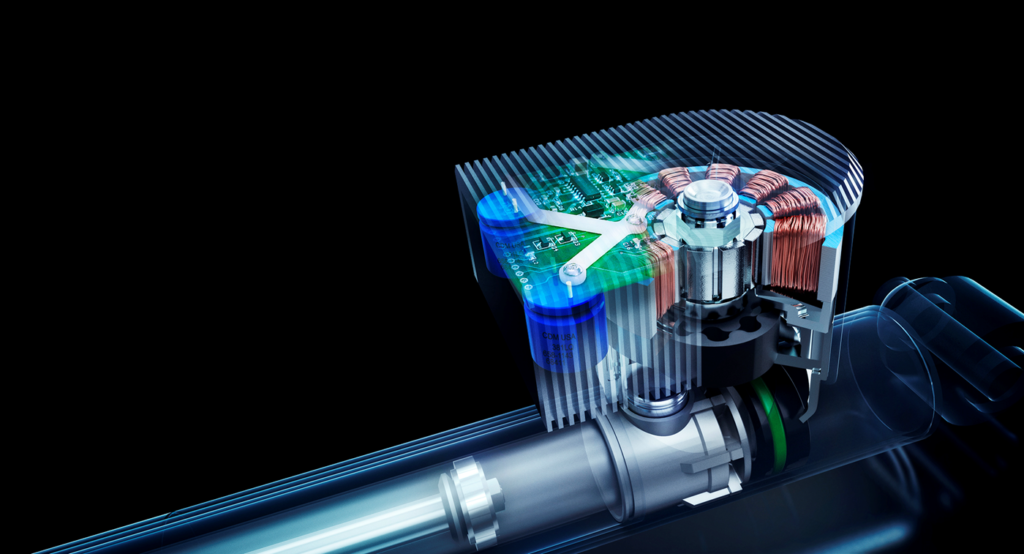

Whether passing the flow of hydraulic fluid past a reversible electromechanical gear pump (pictured above) or moving a magnet inside a coil, making power from suspension movement has the side benefit of providing precise control over both compression and rebound damping by altering the amount of resistance created in the electricity-generating components.

In the case of a system developed by Audi (below), dampers are replaced by horizontally arranged electric motors that intrude less into the vehicle’s body than upright telescopic shocks, providing more space for luggage, passengers or batteries.

Earlier this year, researchers from the German Aerospace Centre started collaborating with Yamaha to develop thermo-electric generator technology to the point where it could reduce fuel consumption by up to five per cent.

As its name suggests, this system converts heat into electricity, based on the difference in temperature between two surfaces (pictured above).

Yamaha has been working on this technology since 1998, and spokesman Kenji Arakawa told WardsAuto it plans to apply it “not only to conventional gasoline engines, but also to diesel and hybrid vehicles”.

The most obvious way of using thermo-electric generators in vehicles is to place them between the exhaust system and a coolant circuit.

Questions remain over how the current low conversion yield of this technology can be improved to meaningful levels. The rare and toxic materials required could also inhibit large-scale manufacture.

But the German-Japanese research team is confident that getting the price down and production volume up will not take long.

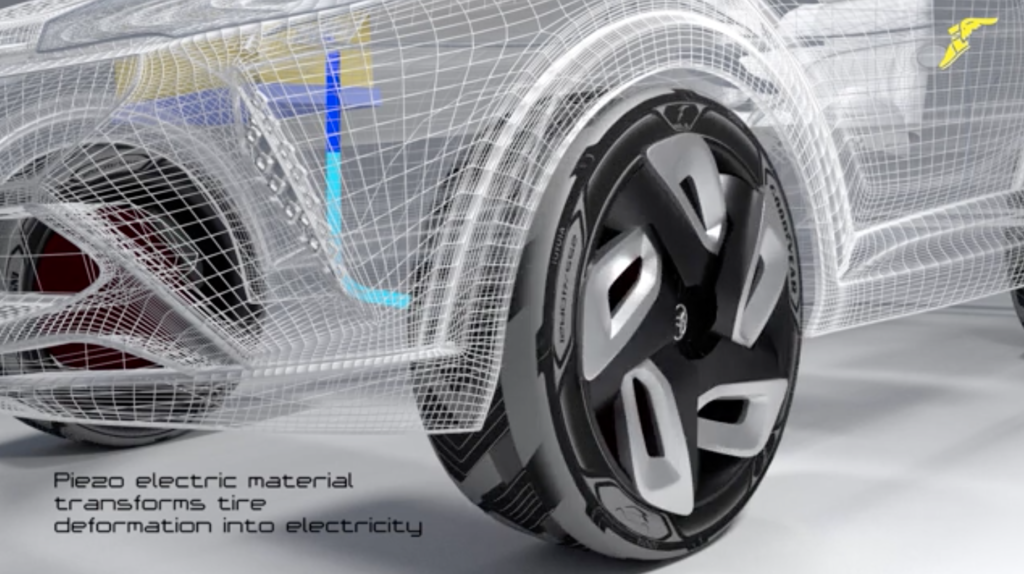

At the 2015 Geneva motor show, Goodyear introduced a concept tyre (pictured below) with embedded thermal capture materials that converts heat caused by road friction or sunlight, as well as motion of the tyre, into electricity that can be fed into the vehicle’s battery.

This tyre technology remains a concept, with no timeline for it to become production reality.

Racing improves the breed

Leading F1 teams claim their race engines are upwards of 45 per cent thermally efficient, with some closing in on 47 per cent on the way to a goal of 50 per cent.

Mercedes AMG High Performance Powertrains managing director Andy Cowell foresees a day when the C-Class is powered by a 400cc V-twin engine with F1-like thermal efficiency, at the heart of a petrol-electric hybrid system.

“Let’s start talking about cc and not litres,” he told ESPN. ”So a 400cc, 90-degree, v-twin with 200bhp!”

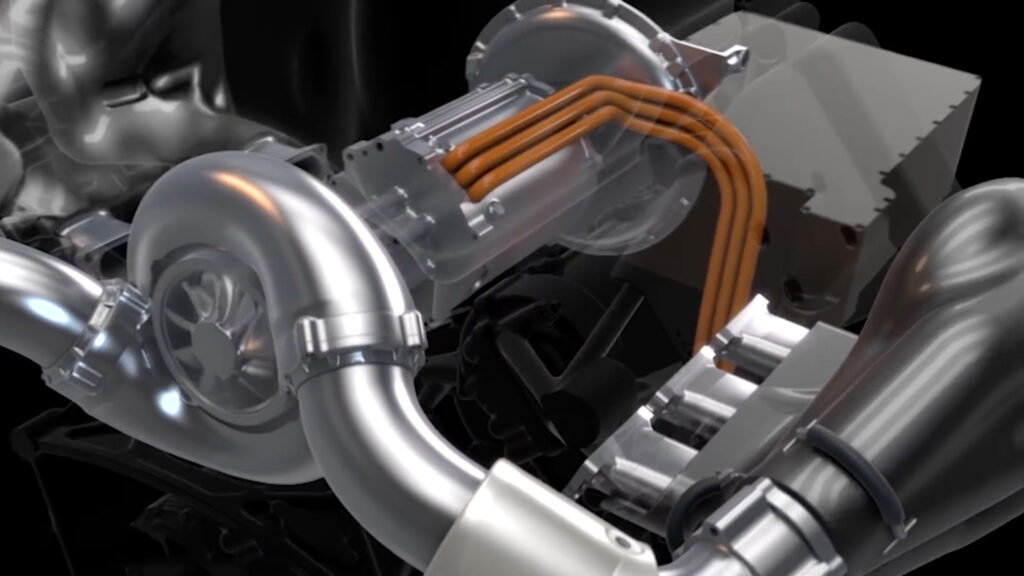

In addition to regenerative braking, Mr Cowell’s vision would use an F1-style MGU-H turbo (pictured below) with a motor-generator attached to the shaft that eliminates lag and is also used to generate electricity from exhaust gasflow under full-throttle conditions.

“You would have a miniaturised version of the F1 assembly to recover energy from the turbine and you would use that when you really want to get away from the traffic lights,” he said.

“So you’d have the front drive motors providing four-wheel drive, you’d have the engine pulling you away and then when you want to do your zero emissions around town, you would have used the engine in the suburbs to make sure the battery is full.”

It has been argued that such high-efficiency combustion engines are more energy-efficient than electric vehicles charged from coal- or gas-fired power stations. However, this argument fails to take into account the energy used to drill, transport and refine crude oil before it can be burnt as petrol in an engine.

For the internal combustion engine to have a future, increasing its thermal efficiency by any means will be key to its survival.

One thing is certain: Automotive cooling and electrical systems will become ever more embedded in and integral to the drivetrain.

- CategoriesIn SightGlass

- TagsSightGlass News Issue 10