Inside Autodata

- PostedPublished 3 April 2015

Behind the scenes: A painstaking wiring diagram process

Talent, dedication, patience and time. A lot of time. This is just a fraction of what goes into creating the Autodata wiring diagrams used daily in thousands of workshops across Australia and New Zealand, plus countless more around the world.

SightGlass News discovered just how much work goes into the Autodata product during a behind-the-scenes tour of the British company’s Australian headquarters in Brisbane, where almost 2600 wiring diagrams have been created in the past three years alone.

As part of VASA’s partnership with Autodata, some of these diagrams are included in the new member-exclusive SightGlass Tech bulletins.

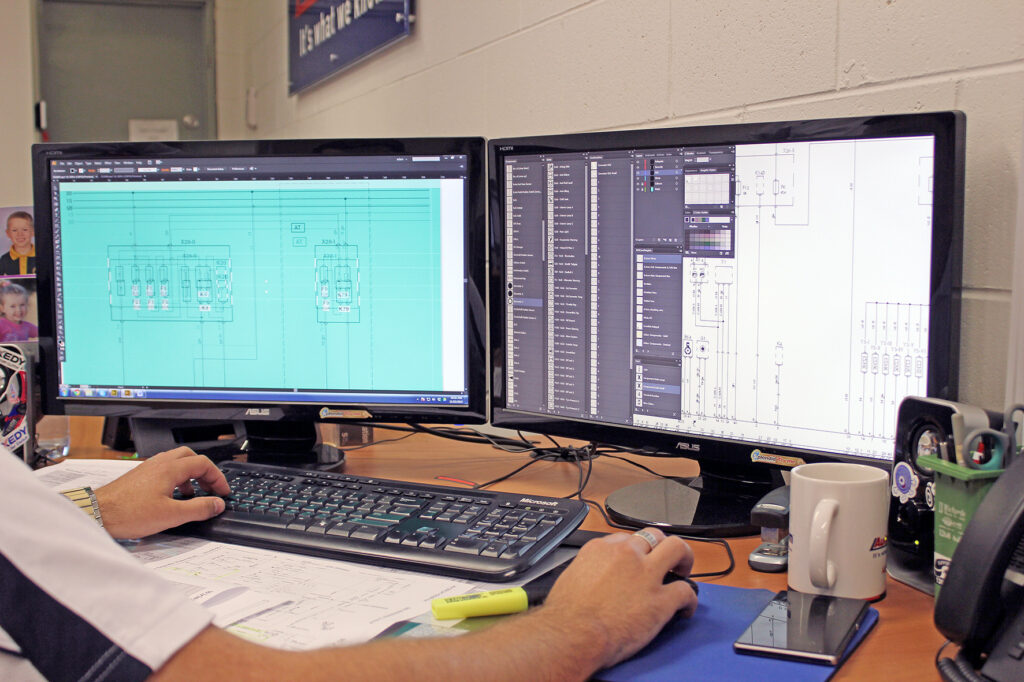

Adam Maynard, a young ex-Holden technician, sits at his desk in a comfortable office that bears no resemblance to the warehouse racks that once occupied this space in the days before everything went online, and Autodata was still shipping books and CDs.

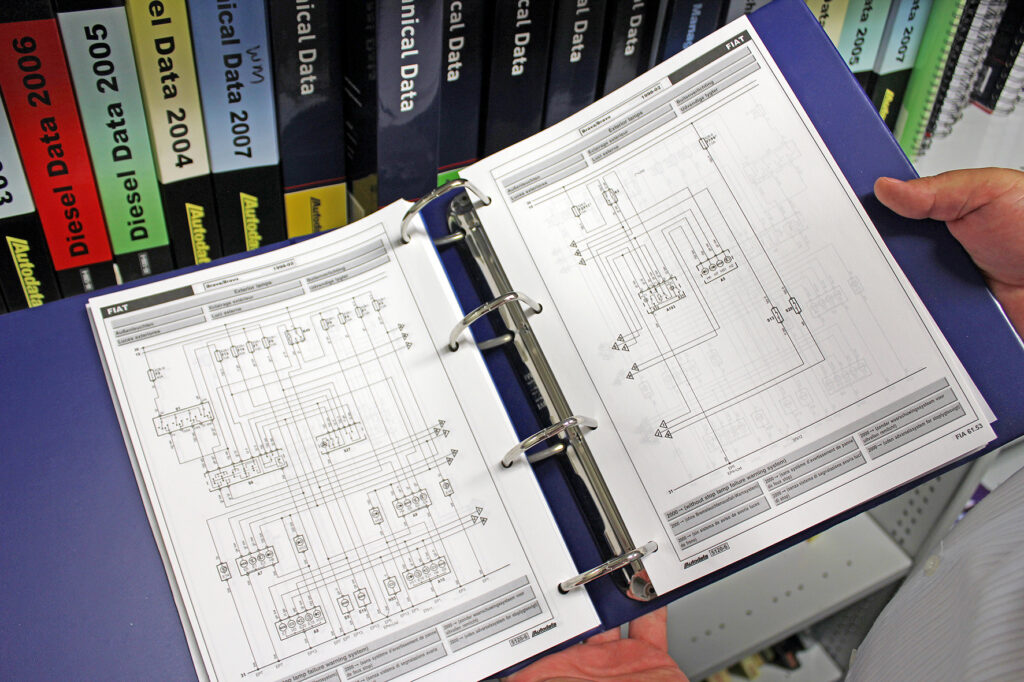

Attached to one of Adam’s two computer screens are family photos, beside him a huge lever-arch file containing an official factory Ford FG Series II Falcon workshop manual.

Adam shows me the wiring diagram in the Ford manual he is using as an information source. As Ford had combined the starting and charging circuits onto a single one-page diagram, Adam has used a highlighter pen to isolate the two circuits so he can create separate diagrams.

To demonstrate how different the source materials are for each manufacturer, Adam reaches for a Nissan D22 Navara workshop manual in which the wiring diagrams are broken down to show only the sections affected by specific diagnostic trouble codes.

My mind starts to melt as I try to understand how Adam accurately translates innumerable separate sections of circuit into Autodata’s easy-to-use schematic style, which was established around 25 years ago. The Nissan and Ford diagrams are as different as night and day – and there are dozens more manufacturers, all with their own formats for Adam to get his head around.

To ensure consistency and ease of use for technicians flipping from one vehicle to the next, Autodata sets strict rules on the layout of wiring diagrams. For example, fuel pumps are on the left, ECUs are central – regardless of the many ways source information might be laid out.

It is the same story for wiring colours. Each has a standard Autodata code – for example yellow is ‘ge’. Similarly, if you have ever wondered why some of the wording used in Autodata seems a bit odd, it is to ensure it accurately translates into all 17 languages in which it is published around the world.

The rules mean Adam’s diagrams match the format of those produced at Autodata’s global headquarters in the UK, where the wiring diagram team alone outnumbers him ten-to-one. Similar-sized or even larger teams work on other information categories.

Adam says that on average, a set of wiring diagrams for one car takes 160 man hours but on highly complex vehicles the power distribution diagram alone can take a month. But that’s not the end of it.

Once Adam has finished drawing each diagram, he must identify and list all the electrical components featured.

Because Autodata diagrams are interactive, they must all be accompanied by a document full of XML computer language that among other things, lists every electrical component in the circuit. Each component has its own designation, drawn from Autodata’s constantly growing master list – which currently contains around 2000 entries.

Adam must carefully select each component from the master list for inclusion in the XML file. To my eyes the repetitive, robotic-looking XML document looks easy to get lost in but Adam is unfazed.

And if a type of component in a circuit is duplicated (such as multiple cooling fan relays) the component codes must be suffixed by a number and this replicated in new lines of the XML document.

To make sure he has covered all the diagrams for each vehicle, Adam has a standardised list of ‘chapters’ he must complete (unless they relate to systems not included on that model). Adam seems to use this as much as a work plan as a way of making sure he’s covered everything on the vehicle.

Some diagrams must also be created to be print-friendly, spanning several pages. Viewed online the whole diagram is visible, but for printing they might be divided into several A4 pages. For this Adam has to create new versions of diagrams that can spill across more than one page, complete with icons to help users match the points where each part of the circuit has been split.

The biggest diagram created in Australia spills across three pages but circuits for some of the European luxury cars can span up to six pages.

We’re still not finished. Once all the diagrams and their associated XML documents are complete, they must be sent to Adam’s UK counterparts for double- and triple-checking and any problems fixed before the diagrams can be included in the Autodata software.

It can take up to six months from Adam picking up a factory workshop manual to the diagrams appearing online, but with streamlined processes and Autodata’s recently released new online system the aim is to reduce that significantly.

Every diagram has a serial number so it can be traced back to the person who created it and the source material from which they were working.

Adam said there had been a number of cases in which Autodata customers found problems with diagrams subsequently traced back to the official factory manuals.

In one example the diagram was so wrong that when Autodata notified the vehicle manufacturer, it had to withdraw the factory manual and republish it with the diagram fixed. In another, it turned out a manufacturer had changed the colour of a wire because the factory ran out of the old colour and never reflected the change in official manuals.

Wiring diagrams are just one of 25 information types available through the Autodata system. The effort required to compile so much data from disparate and often expensive sources is just mind-boggling.

It’s incredibly labour-intensive work, carried out by skilled and knowledgeable people (Autodata has a policy of recruiting people with a trade background). Then there’s the investment in sourcing official workshop manuals and data from manufacturers (who aren’t always cooperative) plus the infrastructure required to provide a reliable world-wide online service.

Having seen what goes into just one part of Autodata’s product, it starts to look like staggering value for money.

So when you’re next looking at an Autodata wiring diagram, perhaps on the back of your SightGlass Tech bulletin, you can now appreciate the hours of painstaking work Adam and his colleagues put into it.

Manual Mayhem

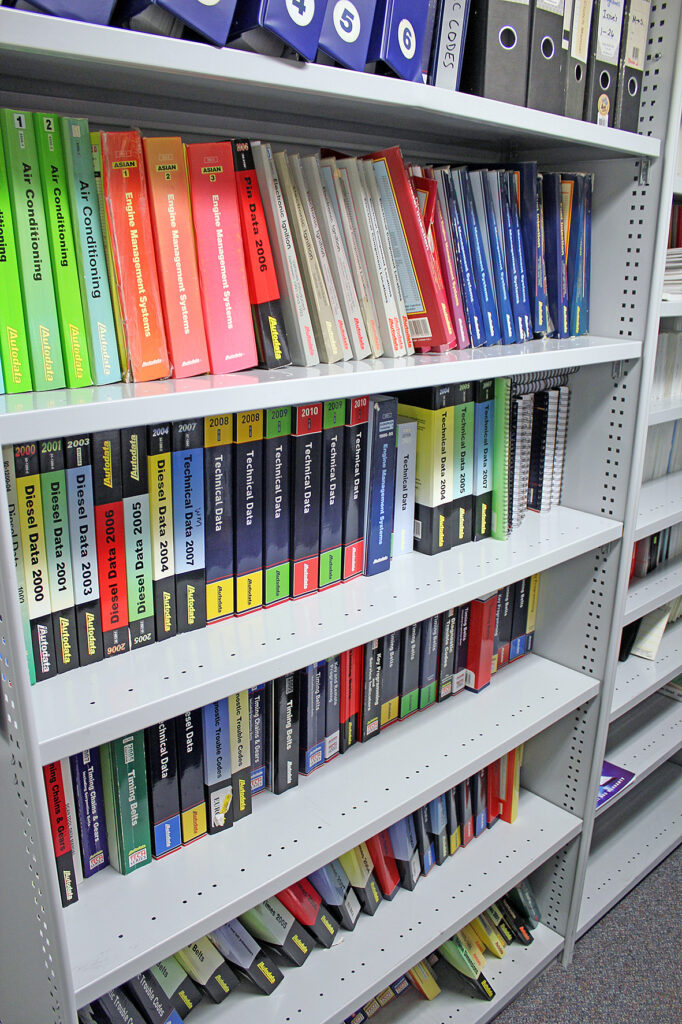

Autodata Australia technical liaison and content manager Wayne Mander allowed SightGlass News into a cornucopia of workshop manuals that would turn an enthusiastic home mechanic – and probably a few professional technicians – green with envy.

Not only is there an archive of Autodata manuals – among them a six-volume archive of wiring diagrams including one in the old pre-schematic style – but official factory manuals and glovebox guides for all sorts of Australian-made and imported vehicles.

An indication of modern vehicle complexity was the 19-volume Toyota Tarago manual, each book the size of a major city’s telephone directory. Imagine the freight on that – and then multiply it by the number of Toyota models out there.

- CategoriesIn SightGlass

- TagsSightGlass News Issue 1