Hacksaw Education

- PostedPublished 14 June 2015

When I tell people that a technique I use during A/C diagnostics is visualising myself as a refrigerant molecule making my way around the internals of an AC system, my audience often allows their focus to wander from the discussion at hand while trying to determine just how crazy I am.

Accurate diagnostics demands an understanding of the system in question. Often, we have a certain type of system behaviour, unwanted behaviour, that we are trying to solve. Visualising the actual conditions within the system at that point in time can be invaluable when it comes to ruling in or out certain plausible scenarios.

When it comes to AC systems, picturing the world as a molecule of refrigerant moving through pipes, hoses and heat exchangers is the easy part. The hard part is knowing exactly what the landscape looks like, and understanding that the landscape can change from one vehicle to the next.

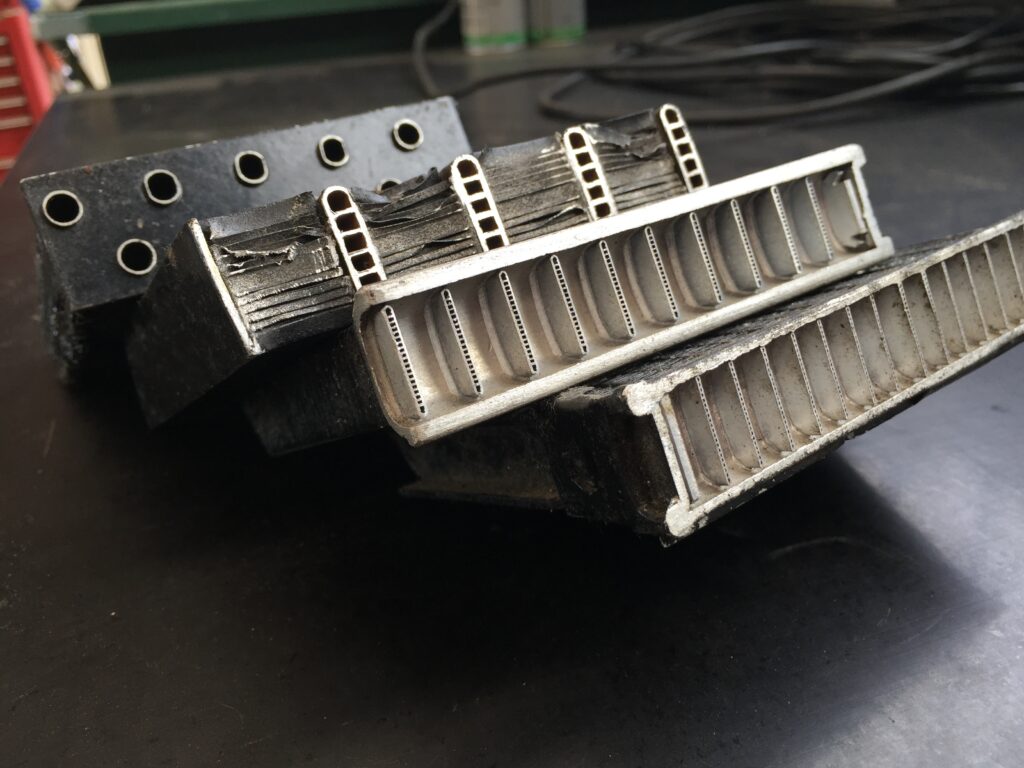

One of the best ways to learn is to apply what I call ‘Hacksaw Education’. It is really easy. All you need is a few minutes of time, perhaps during a break or after work, a hacksaw and a vice. Grab an old component, secure it in the vice, put on your safety glasses and go to town with the hacksaw. Within a few moments you will see it – the landscape that until now was only seen by the refrigerant molecule within.

Heat exchangers will reveal all their secrets once cut open from every angle. You might see debris, excess oil, no oil or interesting discolouration. Just as important is the manufacture of the component – the size, the shape, the galleries, the wall thickness, the welding, the soldering, the fit and finish, and possibly even production errors that had gone unnoticed.

There is so much to learn by cutting things open, or by dismantling them piece by piece. Compressors are a must (usually not by hacksaw!), however Evaporators, Condensers and Driers are my favourite things to chop up. Seeing inside, studying the construction, the refrigerant paths, the evolution and thinking behind the engineering, will give you a competitive advantage in your diagnostic endeavours. You will look at your gauges differently, with a deeper understanding of what is actually going on at a molecular level.

Go to it, drag some dead items from your scrap metal bin and work up a sweat with the hacksaw. You never know what you might find, or what you might learn.

- CategoriesIn SightGlass

- TagsSightGlass News Issue 2, Training