Tesla’s innovative ‘tabless’ cell design reduces complexity and increases performance

- PostedPublished 10 December 2020

Tesla is set to introduce a new large “tabless” battery cell that is said to offer significant improvements in efficiency, capacity and ease of production.

Its new cell technology, which was previewed at the Tesla Battery Day event in September, will enable a greater vehicle range, easier production and reduced costs – all factors that will expedite the wider uptake of electric vehicles.

Tesla originally used 18650 form factor cells which, as indicated by the name, are 18mm in diameter and 65mm tall. By 2017, it had moved to larger 2170 cells that offered 50 per cent more energy.

These cylindrical cells are fabricated from layers wound in spirals, which create long internal electrical paths and require small positive and negative tabs to be welded on at each end.

However, increasing the size of cells further can cause thermal issues due to the increasingly lengthy internal pathways and the compact negative and positive tabs.

Ultimately, this limits charging speeds and makes larger cells unsuitable for long-life electric car battery packs.

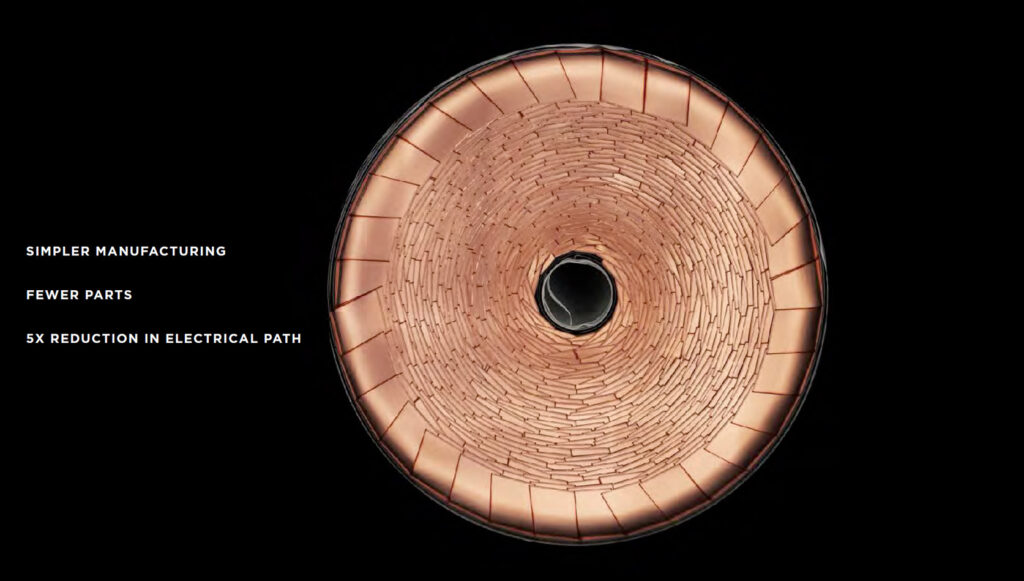

Tesla’s new 4680 cells, to avoid these issues, have a “shingled spiral” internal construction and no fiddly positive or negative tabs that need to be welded on.

It results in a cell with a 50mm internal electrical path instead of 250mm, requires fewer parts and is easier to make.

The new form factor alone, according to Tesla, would grant a 16 per cent range increase for electric cars compared with similarly specified conventional cylindrical cells – and it also permits a cost reduction of 14 per cent on the dollar per kWh figure.

A new 4680 is additionally reputed to offer five times the energy and six times the power of the company’s existing cells, although exact figures are yet to be published.

Production of the cells has already started at the company’s pilot battery plant near its Fremont factory in California, which is expected to produce 10GWh worth of batteries each year when up to speed.

Tesla CEO Elon Musk also stated during his Battery Day presentation that full-scale production plants would be more in the region of 200GWh per year.

Tesla’s latest updates are not confined to the design of the cell itself, though.

The company has also sought improvements in production processes, production machinery, battery packaging, material and chemical formulations to bolster the capabilities of future cells and packs while reducing costs and environmental impacts.

For example, Tesla is aiming to phase down the use of controversial and expensive cobalt in the cathodes of its lithium-ion batteries. Instead, it will use more affordable nickel.

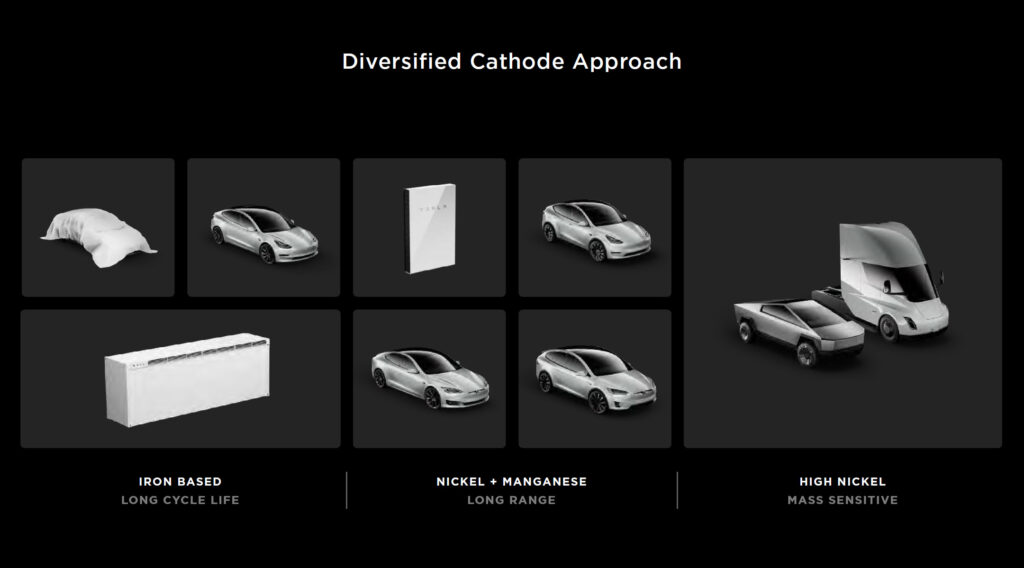

The company is also considering a diversified approach to cathodes, using iron in long-life applications, nickel and manganese in long-range vehicles and a high nickel content for weight-sensitive applications.

A new variant of the Model S, called the Plaid, was also detailed at the event.

The high-performance electric vehicle has a claimed 0-100km/h time of around two seconds, a top speed of 322km/h, a power figure in excess of 820kW and a range of more than 830km.

Orders can be placed now and, in Australia, the Model S Plaid starts at $A189,990.

- CategoriesIn SightGlass

- TagsBatteries, battery, electric vehicles, SightGlass News Issue 22, Tesla