SECOND COMING

- PostedPublished 1 November 2017

ELECTRIFIED and self-driving vehicles are presenting curve-balls to suppliers that design, engineer and make thermal management and HVAC systems.

This is having an impact on refrigerant choices, because while R1234yf is great for conventional air-conditioning and R744 is better for heat pumps in low ambients, YF comes into its own again when scavenging heat from powerful computers that provide autonomous driving capabilities.

At the same time, development of secondary-loop systems has resumed, which puts refrigerants with higher levels of flammability, such as R152a and even hydrocarbons, back in the frame for automotive applications.

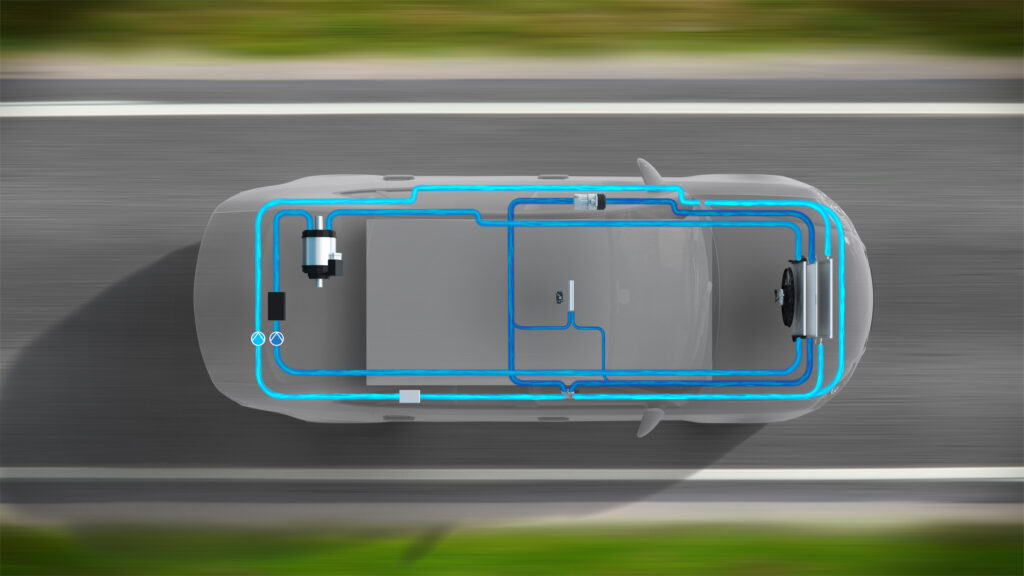

Because HVAC is becoming increasingly intertwined with the thermal management of drivetrains and on-board technology, it seems inevitable that secondary-loop systems will become the norm.

The persisting high cost of YF to vehicle manufacturers and end users alike is also creating an environment where further alternatives start to look attractive.

At the Frankfurt motor show, SightGlass News spoke with Markus Wawzyniak, director of air-conditioning and thermal management pre-development at German component supplier Mahle, which is co-developing a secondary-loop AC system with Jaguar Land Rover parent company Tata.

He explained that before YF became the commonly accepted automotive refrigerant, the German carmakers favoured R744 and Detroit was going down the R152a route, while the French and Asian groups were on the fence.

Stuttgart-based Mahle was naturally in the R744 camp, but acquiring the thermal management division of US automotive supplier Delphi in 2015 provided it with access to the team and intellectual property from prior secondary-loop developments.

“It’s interesting now that Mahle and Delphi are coming together because Mahle at the time were always heavily into CO2 whereas Delphi was heavily engaged in secondary-loop R152a systems,” he said.

“We were technical adversaries at the time, [but] now the two companies joining forces is allowing us to bring together both sides of the coin.”

Dr Wawzyniak said that in 2005 a secondary-loop system “didn’t make much sense” and that while R152a was a “decent” refrigerant, the efficiency compromises of secondary-loop “takes away some of its charm”.

Today and into the future, vehicles with idle-stop or even engine-off coasting can take advantage of what Dr Wawzyniak described as the “inherent thermal momentum” of secondary-loop systems.

“Benefits lie in the start-stop operation, in the minimisation of refrigerant volume [and] you can make a very compact system in the engine compartment so you can offset some of the thermodynamic disadvantages,” he said.

“Of course if you can make some technical sense out of a secondary-loop system, then it might make perfect sense.”

Electrifying developments

Dr Wawzyniak said the automotive industry is having “quite a bit of discussion” about the application of secondary-loop systems in electrified vehicles.

What’s more, both Delphi and Mahle had previously researched this matter, the former using synthetic refrigerants and the latter on R744.

And the conclusion is positive.

”The benefit of using indirect system in electrified vehicles is mainly collecting waste heat from different components because you have your drive motor, your battery, your drive electronics, they all happen to reside at different temperatures,” he said.

“If you were to collect the energy using refrigerant loops that would incur complexities. If you had a secondary loop system it is probably much easier to collect waste energy from electrical components.

“That’s why also Mahle, which has not been so into secondary-loop system in the past has sided with secondary-loop systems for electrified vehicles.”

Relevance for internal combustion

The Tata project is for a non-electrified vehicle, although Dr Wawzyniak suggested it has some form of advanced idle-stop.

“For Tata they have some fuel-efficiency benefits that you can see with predictive driving and so-on,” he said.

“You have a thermal storage built in, as your vehicle is going downhill or you are cruising you can run your compressor at higher engagement to cool down your system and then instead of using fuel to propel the vehicle and compressor you can operate out of that cold storage system.”

Counting the cost

Mahle struggles to determine if the extra component cost of a secondary-loop system could be offset by R152a being much cheaper than YF, because it makes components rather than whole systems

But Dr Wawzyniak said that compared with a decade ago, carmakers now have a clearer picture of YF’s cost implications.

“While the hardware for the [YF] system is quite comparable to the R134a system, the refrigerant itself of course is much more expensive, so now bringing in an alternative [refrigerant] is, from an OEM point of view, of interest.”

Increased interest in secondary-loop, combined increased electrification and the adoption of heat pumps is also causing engineers to look at YF alternatives.

“YF is not a very good heat pump refrigerant in terms of the performance in low ambient conditions, so maybe CO2 or maybe also some hydrocarbons might have benefits,” said Dr Wawzyniak.

Despite this, he did not expect carmakers to ditch YF any time soon.

“In terms of combustion engine driven vehicles I do not sense in the market an imminent urge to find a replacement quickly for YF,” he said.

- CategoriesIn SightGlass

- TagsSightGlass News Issue 11