Global EV sales escalate as options widen and tech advances

- PostedPublished 1 December 2018

MORE than one million plug-in electric vehicles have now been sold in the US, marking a significant milestone in the uptake of low- and zero-emissions vehicles.

It is not only in the US that battery-powered cars are establishing a significant foothold, though; the number of EVs in both Europe and China recently surpassed the million mark and, globally, more than four million battery and plug-in hybrid vehicles have now been sold.

Unsurprisingly, as many manufacturers respond to increasingly stringent emissions regulations and climbing customer demand, the line-up of low- and zero-emissions cars available is growing rapidly – with recent additions including cars such as the all-electric Hyundai Kona and Jaguar I-Pace, as well as numerous plug-in hybrid variants of existing models.

This, coupled with the increasing capabilities of these cars and wider customer acceptance, is causing sales to surge upwards at remarkable rates; figures published by research organisation Bloomberg New Energy Finance (BNEF) highlighted how it had taken 17 months to go from one million EVs worldwide to two million – yet it took just six months to go from three million to four.

The rapidly escalating demand and ongoing development of EVs will cause a significant surge in demand for components including motors, controllers, cooling systems and batteries.

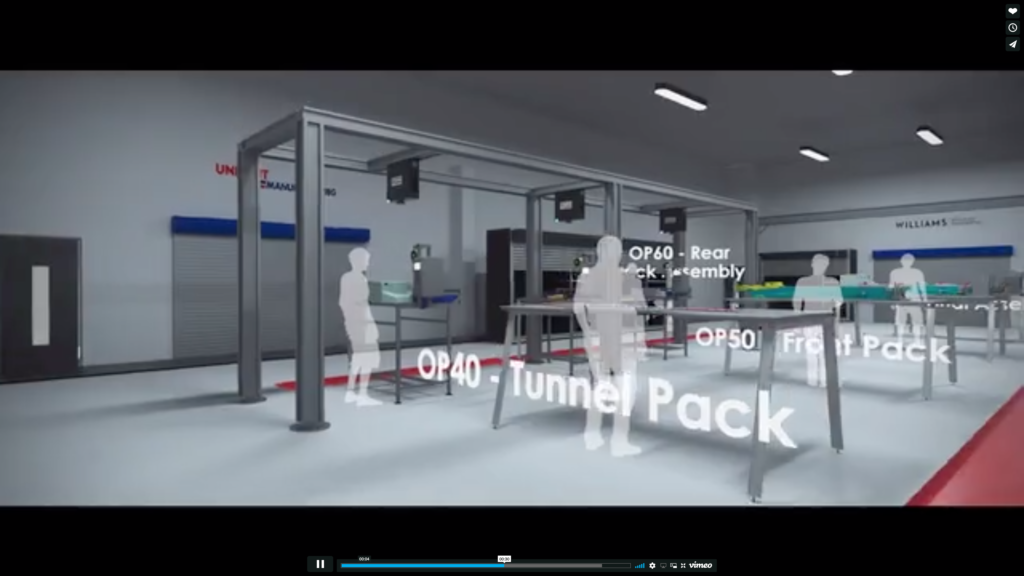

Unsurprisingly, as a result, many companies and start-ups are moving to capitalise on this booming market segment – including well-established brands such as UK-based Williams Advanced Engineering and the long-established Unipart Manufacturing Group. In September 2018, the two announced a new joint venture that is mooted to result in the creation of the UK’s largest independent vehicle battery manufacturer.

The new company, called Hyperbat, will have a factory based in Coventry and is due to open its doors in early 2019. It will design, develop and produce high-performance vehicle batteries, allowing UK-based companies to draw on a local supplier for reliable and durable EV power packs.

This new joint venture has also already secured its first customer, as it is due to supply batteries for the recently announced Aston Martin Rapide E.

Companies continue to study methods to extend the range of current battery technology, too. Hyundai and Kia recently announced that they are developing a new series of solar panels that can be applied to electric, hybrid and internal combustion-engined vehicles.

Reportedly, in the case of the hybrid, the new panel array can charge 30-60 per cent of the battery per day.

A series of new designs are proposed, including a panel that covers the roof and a translucent array that also serves as a panoramic roof (see main image).

Solar panels that cover the bonnet are being considered for more eco-friendly models; in any case, these panels – mooted to arrive in 2019 – will deliver far more power than the optional spoiler-mounted token gesture found on cars such as the Nissan Leaf.

Despite all this, there are still numerous challenges faced by electrics cars, and hurdles that need to be overcome, in order to ensure that they are both viable and safe.

In New Zealand, for example, any imported car must be disinfested to ensure no foreign pests make it into the car. This process, though, involves heating the car to in excess of 60°C. VIA, the organisation that represents vehicle importers in NZ, rightly raised concerns that this might cause problems for the batteries in electric vehicles; fortunately, comprehensive testing revealed that the temperature of the battery remained well within safe limits.

This is one instance where legislation and testing procedures haven’t moved quickly enough with the times. In a similar fashion, the European Union finally announced new legislation to ensure that all electric cars sold from July 2019 on will emit noise at low speeds – to help avoid accidents involving pedestrians, particularly those who are visually impaired or deaf.

While many already emit noise at low speeds, some have no sound system or it is a cost option. Under the new rules, all will have to make a noise in excess of 56db(A) and at speeds up to 20km/h. The new all-electric Jaguar I-Pace is the first to meet and exceed these upcoming regulations, featuring a new system called AVAS – Audible Vehicle Alert System.

Iain Suffield, Jaguar Land Rover’s noise, vibration and harshness technical specialist, said: “It’s not just a flat sound – the car moves, it accelerates, it decelerates, it starts, it stops, and the sound must reflect that behaviour. We do an awful lot more listening than we do looking.”

- CategoriesIn SightGlass

- Tagselectric vehicles, EV, SightGlass News Issue 15