Mahle climatic wind tunnel “goes electric”

- PostedPublished 12 October 2023

Mahle, a German automotive component supplier that provides engineering and consulting services to automakers, says it is reorienting itself in light of the electrification transition.

It has recently equipped its climatic wind tunnel in Stuttgart with a DC fast charging system, as Mahle management believes the company’s sales potential in relation to electric vehicles (EVs) will be three times higher compared against its internal combustion engine business.

Mahle engineers can now charge electric vehicles in all climatic conditions, including extreme heat, to gather data regarding the impact on the battery and passenger comfort.

The test facility offers accurate, repeatable, and realistic measuring, effectively bringing the road into the lab.

A quick charge cycle at 40°C (104°F) in direct sunlight with little wind cooling would be an extreme heat example.

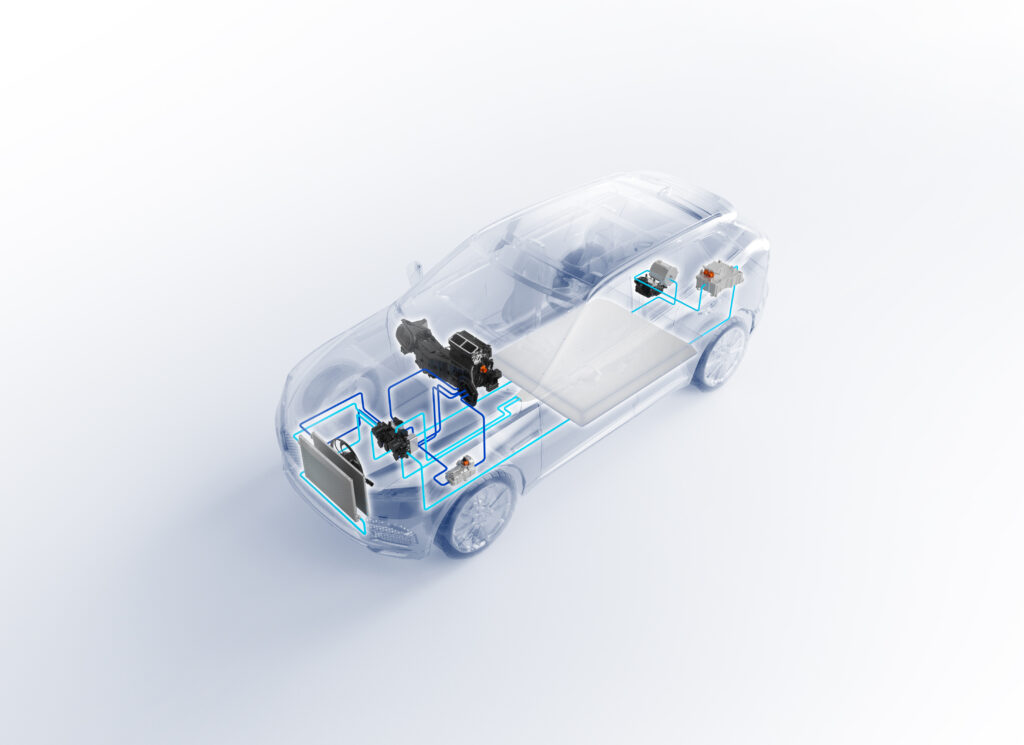

These are challenging circumstances that put a heavy heat burden on a lithium-ion battery and a vehicle’s thermal management system, which manages the complex interactions between the air-conditioning and battery cooling systems, ensuring that neither the passenger compartment nor battery pack overheats.

It does this by keeping the energy cells in the optimal temperature range of 15°C up to a maximum of 40°C (59°F to 104°F) for maximum charging performance.

Such test scenarios can now be simulated and accurately measured to provide automakers with information about the effects on batteries and passenger comfort and to aid in vehicle component design, calibration, and integration for hybridised internal combustion engines and electrified powertrain systems more broadly.

“By expanding the range of services offered by our climatic wind tunnel in the direction of e-mobility, we will be able to support our customers even better in the development of their e-cars in the future,” said Jumana Al-Sibai, a member of the Mahle management board and responsible for the company’s thermal management business unit.

“The battery is particularly demanding, and Mahle can make a valuable contribution here with its distinctive system expertise in temperature management.”

Mahle says it remains the most prominent vendor of high-efficiency modular thermal management systems for automotive drivetrains and interior comfort.

It currently sells the most powerful electric compressor on the market, with a peak power of 18kW. To date, its total order volume for electric compressors stands at A$2.3 billion.

“With a large number of innovative, high-efficiency products for e-mobility and our proven system competence in thermal management, we will leverage growth opportunities,” said CEO Arnd Franz at the annual Mahle press conference held in Stuttgart, where the company also launched its corporate strategy, “Mahle 2030+”.

This focuses on electrification, thermal management systems for drivetrains and interior comfort, and components for highly efficient, green internal combustion engines powered by hydrogen and synthetic fuels.

“Our customers appreciate our continued support for the internal combustion engine in connection with our strategy,” said Franz.

Mahle built the world’s first wind tunnel for the automotive industry in 1937 at its testing facility in Stuttgart.

In 2000, it was completely modernised as part of a new construction and has since been continuously developed, keeping it at the forefront of the measurement sector.

- CategoriesIn SightGlass

- TagsClimate control, Mahle, SightGlass News Issue 29, thermal management