Major new market for automotive thermal management

- PostedPublished 16 September 2021

Increasing EV capabilities herald boom in advanced thermal management market

Cars powered by internal combustion engines face all manner of thermal management challenges. Myriad fluids and cooling packs have to be kept at sensible temperatures, and performance issues and damage can ensue if things get out of line.

Electric vehicles (EVs), however, are not exempt from heat-related issues. In particular, the temperature of the drive battery can be problematic – if it gets too hot, due to charging or heavy use, it can degrade, become unreliable and even suffer from a thermal runaway.

At the other end of the scale, cold temperatures can reduce a battery’s output and cut the range of an electric vehicle. Charging speeds can be reduced, too, due to the sluggish nature of the chemical reactions within the cold battery.

Consequently, manufacturers are relying on increasingly advanced thermal management systems that strive to maintain the battery at its optimum temperature – and ensure safe, reliable and effective long service, while granting the high-speed charging capabilities demanded by customers.

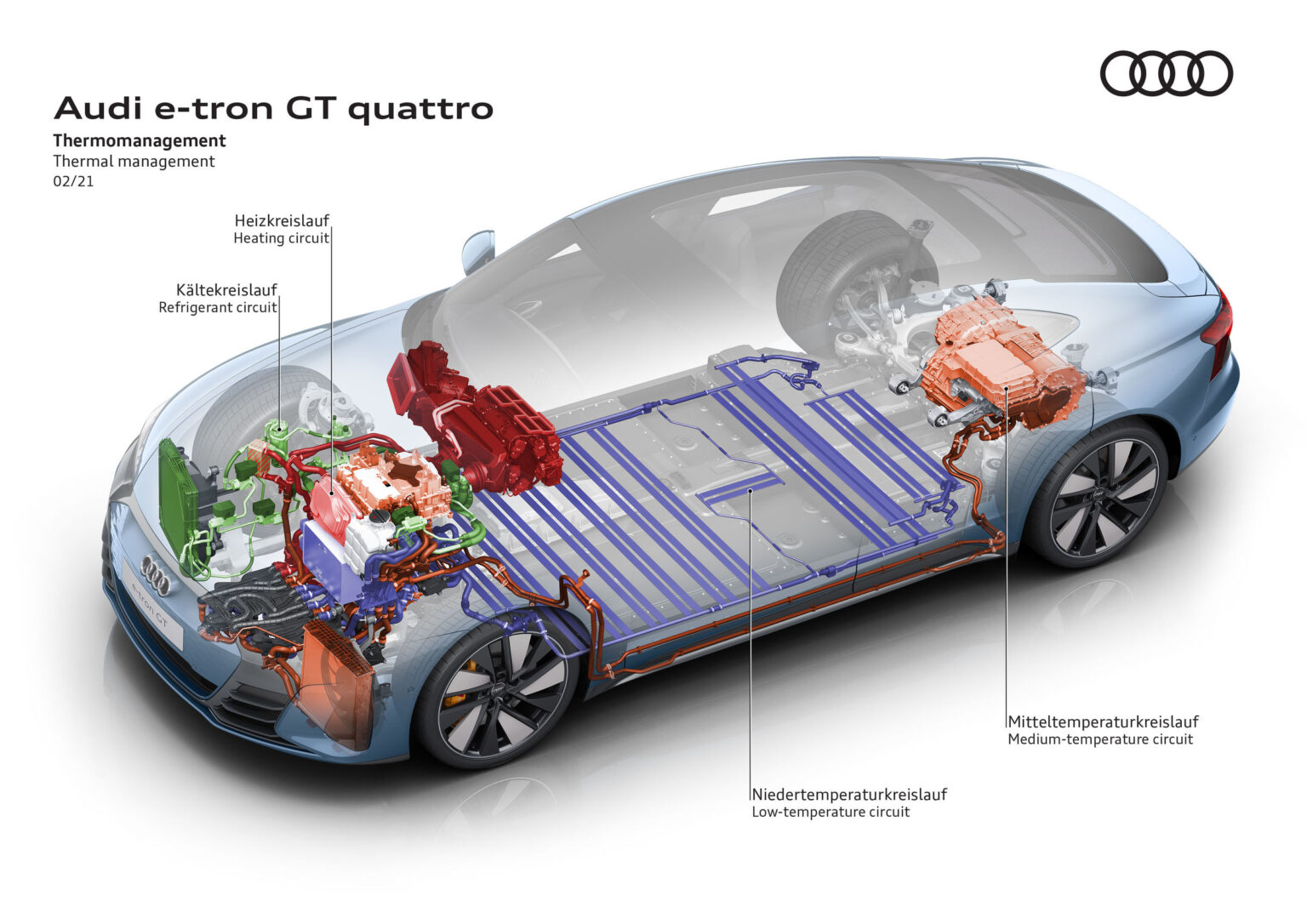

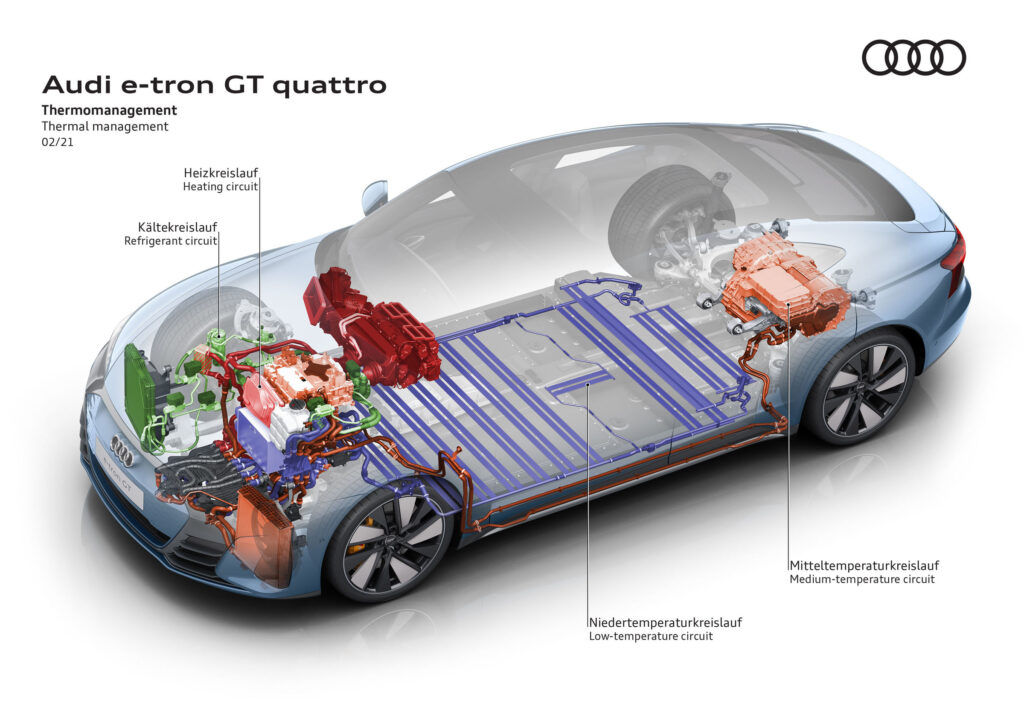

Audi, for example, states that the optimum temperature range of the 84kWh battery in its new e-tron GT is between 30-35°C.

In order to maintain that, in an operating range of -30 to +50°C, a controlled and dedicated glycol-water mixture is circulated underneath the battery.

The vehicle’s refrigerant circuit for cabin cooling can also be tied into the battery-cooling circuit on demand, in order to maintain output and performance.

Additionally, when a high-speed charger is entered as a navigation destination, the battery cooling is intensified to ensure that it can be charged quickly. If it is too cold, on the other hand, it will be heated to grant safe and rapid charging.

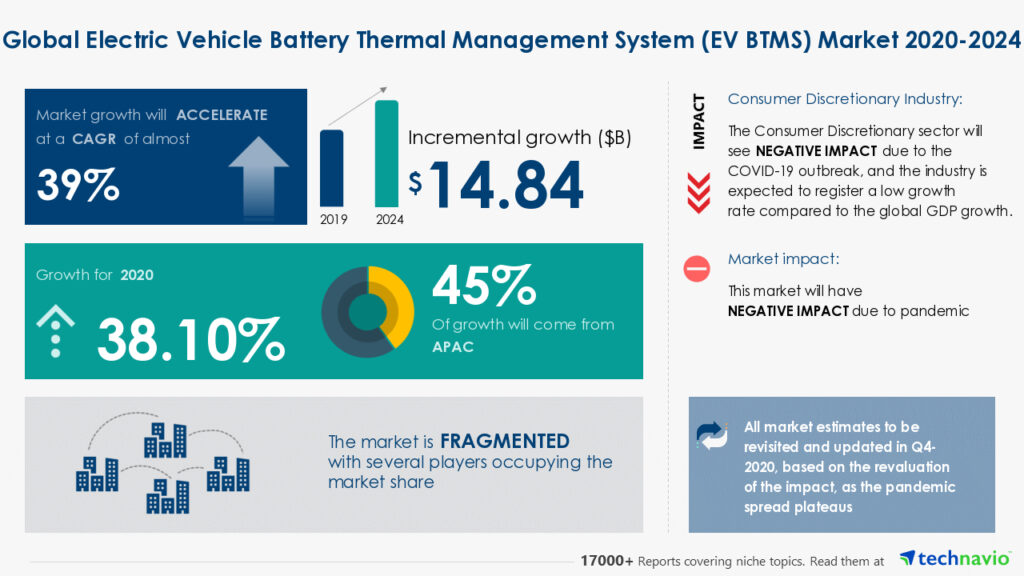

An effective thermal management system is therefore essential to ensuring the best range, performance, usability, reliability and safety – and, due to growing demands and volume production, the market for such technology is expected to grow significantly in the coming years.

Technology research company Technavio, which analyses market trends, forecasts that the thermal management system market will grow by $14.84 billion ($A19.24 billion) during 2020-2024. It also reputed to have grown by 38.1 per cent in 2020 alone, showcasing the dramatic scale of expansion.

New systems, cell designs and formulations for batteries are being experimented with, too, in order to optimise performance – and computer simulation technology is also playing its part.

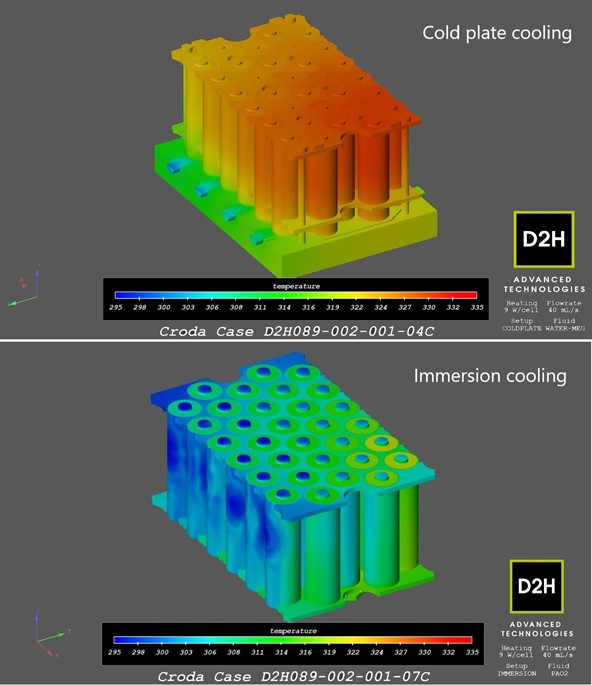

Recently, in the UK, engineering specialists D2H Advanced Technologies used innovative battery simulation tools to enhance the fast-charging thermals of a production electric vehicle.

The problem was one of coolant pump power requirements and noise, caused by high heat levels generated during a fast charge. D2H, using computer modelling, identified that a dielectric fluid from chemical specialist Croda would better dissipate the heat being generated.

The concept was then proven in physical tests, with the fluid granting more stable characteristics. D2H, which was founded in 2015, also trialled an immersive cooling system that offered far fewer hot spots and reduced temperatures.

Kyle Thompson, energy technologies team member at Croda Europa, said: “Providing efficiency benefits to existing battery technologies is only the first stage – and we look forward to showcasing the potential of refined cooling techniques on next-generation vehicles.”

Materials science to improve EV thermal management

The bulk of developments in electrified vehicle thermal management have centred on battery packs, but thermal compound specialist Coolmag is pushing for similar advancements when it comes to on-board chargers, inverters and other power electronics.

“Most of the problems that affect lithium batteries in electric vehicles (pressure, heating, short circuits, fire hazards) are also common to power electronic circuits and therefore the same solutions apply,” the company says in an article.

Coolmag places the blame for thermal management failures on the presence of air inside or between components, as well as the use of thermal insulators as structural components.

It also poses the question: “Why has thermal conductivity always been more influential than thermal resistance or thermal diffusivity?”

The company suggests 3D designs are used to manage thermal conductivity in power electronics.

“Continued demand for more power at lower cost, weight and volume is pushing electronic engineers to design to the limit and in record time,” says the article.

With clever, considered use of certain compounds and methods developed by Coolmag, it is claimed that working temperatures of high-stress EV power electronic systems can be reduced by as much as 40 per cent.

It follows that improving thermal management this dramatically has performance and lifespan benefits for components and systems.

There are also reduced fire risks and the potential for lower production costs if manufacturers decide to use parts that are rated for a lower peak heat stress threshold.

Castrol gears up for EV revolution

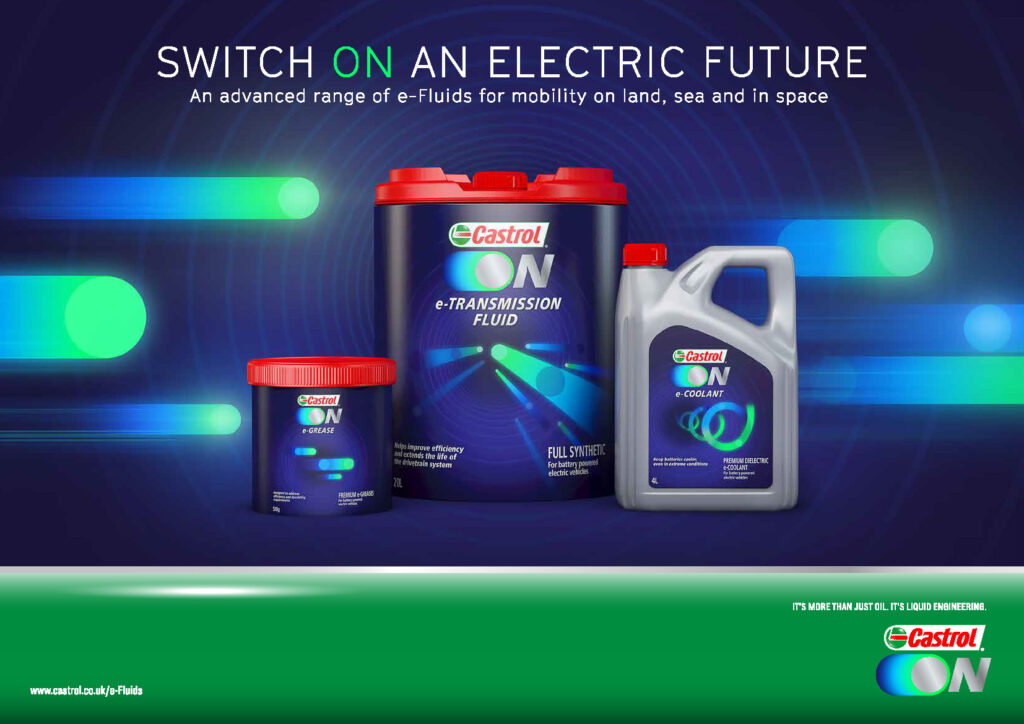

Lubrication and fluid specialist Castrol has launched a new brand, featuring products designed specifically for electric vehicles (EVs), called Castrol ON.

The new brand will encompass Castrol’s range of e-prefixed EV-specific fluids and grease products, including e-Transmission fluids, e-Greases and e-Coolants.

Each has been developed in conjunction with industry partners, such as the Jaguar Racing Formula E team, and are designed to increase the range, charging speed and longevity of EVs.

Castrol ON e-Transmission fluids, for example, are reputed to improve drivetrain efficiency and grant an increased range compared to mass-market factory-fill fluids – while also providing enhanced protection.

- CategoriesIn SightGlass

- TagsSightglass News Issue 23