ABB develops connectors for EVs that do the hard yards

- PostedPublished 28 October 2023

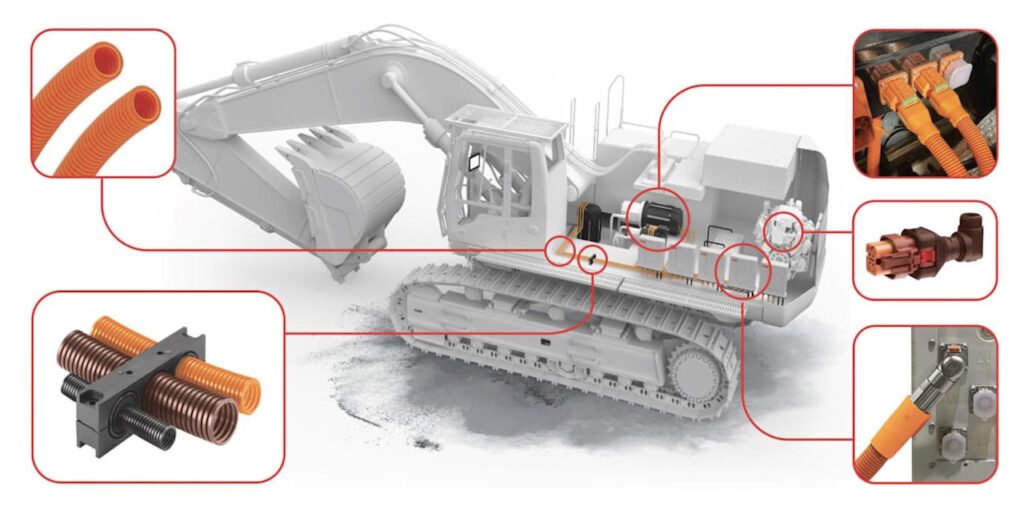

Electrification and automation technology leader ABB has developed the world’s first full range of hinged high-voltage connector backshells to improve cable-to-connector stability in heavy-duty electric vehicles.

Heavy-duty EVs face unique challenges when it comes to wiring, including high engine temperatures, strain, abrasion, vibration, ingress and corrosion.

To address these issues and ensure the reliability and safety of electric vehicles, ABB Installation Products has pioneered a comprehensive cable protection system with its Harnessflex EVO Connector Interfaces.

As countries around the world strive to reduce emissions from heavy-duty vehicles as stricter standards are introduced for fleet and public transport, as well as industrial and farming equipment, more electrical wiring is required in machinery, vehicles and equipment.

“As EV adoption accelerates, ABB is working with vehicle makers, transportation providers and original equipment manufacturers (OEMs) to integrate robust electrical wiring solutions that meet evolving requirements and sustainability objectives, while delivering safer and reliable performance,” said ABB Installation Products’ Andrea Castella, the firm’s EVP and GM of Europe, Asia Pacific, the Middle East, and Africa.

“Harnessflex EVO Connector Interfaces offset the need for expensive, bulky cable clamps in high voltage applications and expands ABB’s electrification solutions for a broad range of demanding and high-use areas of transportation, from construction and agriculture to trucks, buses and trains.”

Designed to exceed industry standards, the Harnessflex EVO Connector Interfaces are said to provide superior protection for critical wiring in high-voltage applications.

Equipped with a tamper-proof clip system for added security, these interfaces provide robust strain relief and prevent debris intrusion. Their vibrant orange colour serves as a visual indicator for high-voltage wiring and components, ensuring easy identification.

ABB Installation Products global business development manager for cable management products Nathan Cook explained that the product “reduces cable movement and forms tighter junction joints for safer and more secure high voltage connections in electric ancillaries, DC-DC converters, onboard chargers, high-voltage battery packs, hybrid systems, hydrogen fuel cell vehicles, and dynamic and static power systems”.

The Harnessflex EVO Connector Interfaces are manufactured at ABB’s Coleshill facility in Britain.

- CategoriesIn SightGlass

- Tagselectric vehicles, EV, mining, SightGlass News Issue 30