All-electric Audi Q4 e-tron features two cooling loops, R744-charged heat pump

- PostedPublished 11 September 2021

For an electric car to deliver the best capabilities and comfort, the temperature of its components and cabin must be managed effectively.

Batteries and control units that get too hot during operation, for example, can cause degraded performance, charging and range issues.

Ineffective cabin heating and cooling solutions, similarly, can result in excessive power draw that significantly reduces the range of the car.

Thermal challenges aren’t unique to electric cars, of course, but the impact some issues can have on factors such as range and battery longevity can prove problematic.

Consequently, to make electric vehicles more dependable, predictable and reliable – and to boost their appeal among buyers – manufacturers are loading their zero-emissions models with advanced thermal management, charging and climate systems.

Take the new Audi Q4 e-tron and Q4 Sportback e-tron SUVs, which were revealed recently. In entry-level form, the all-electric SUV is equipped with a 352-volt battery with a capacity of 51.5kWh and a weight of 350kg.

In higher specifications, each e-tron features a larger battery that packs 76.6kWh and weighs 500kg.

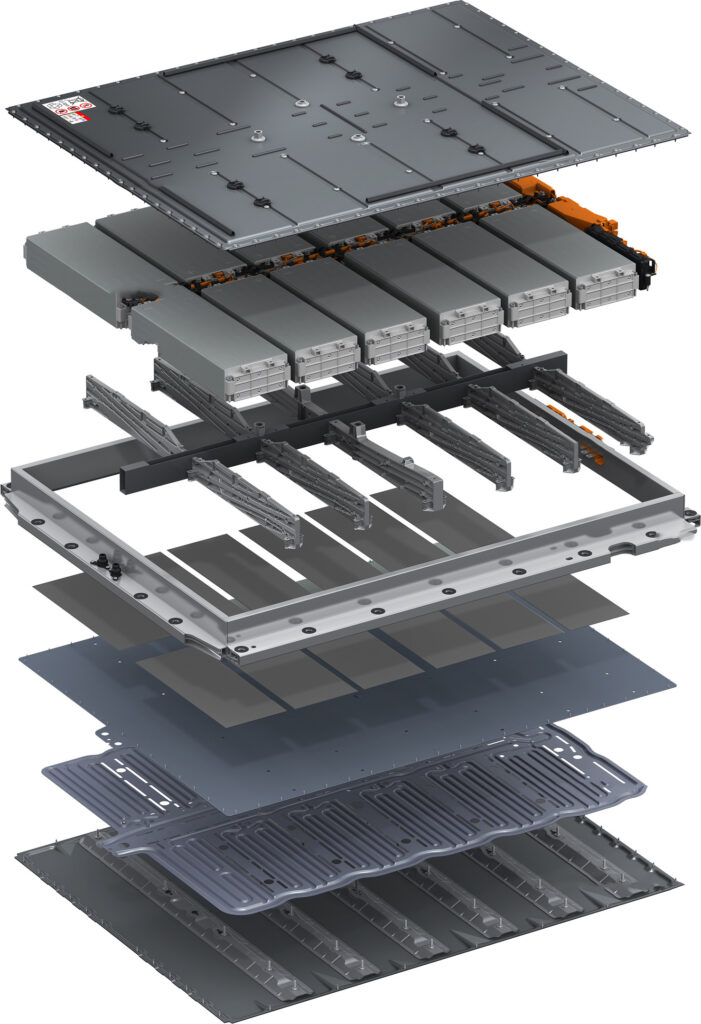

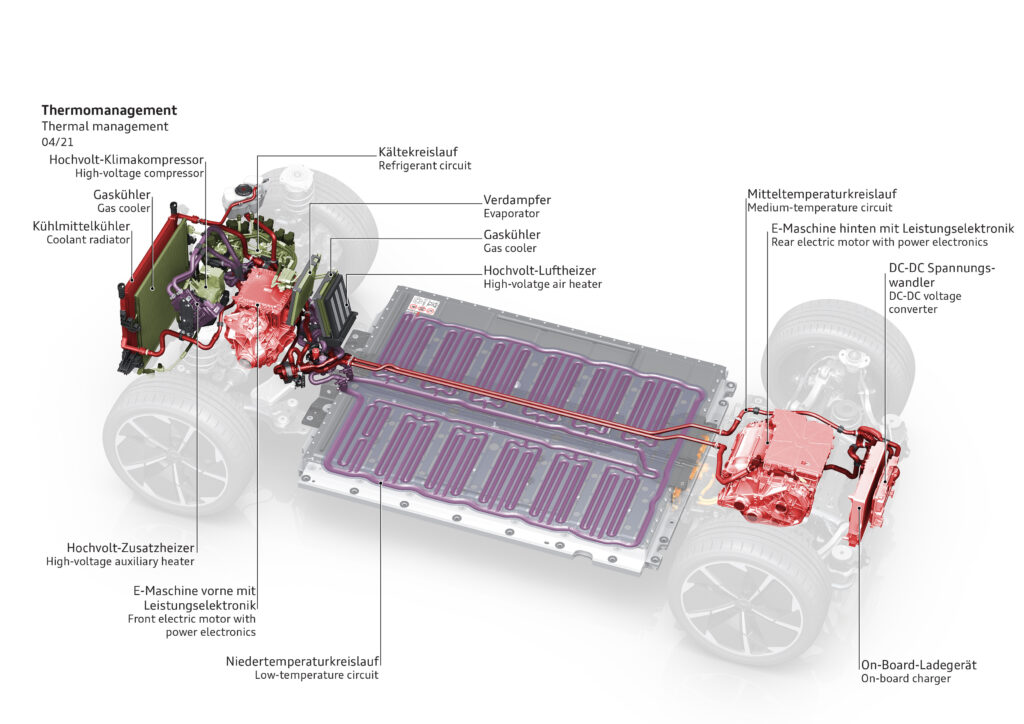

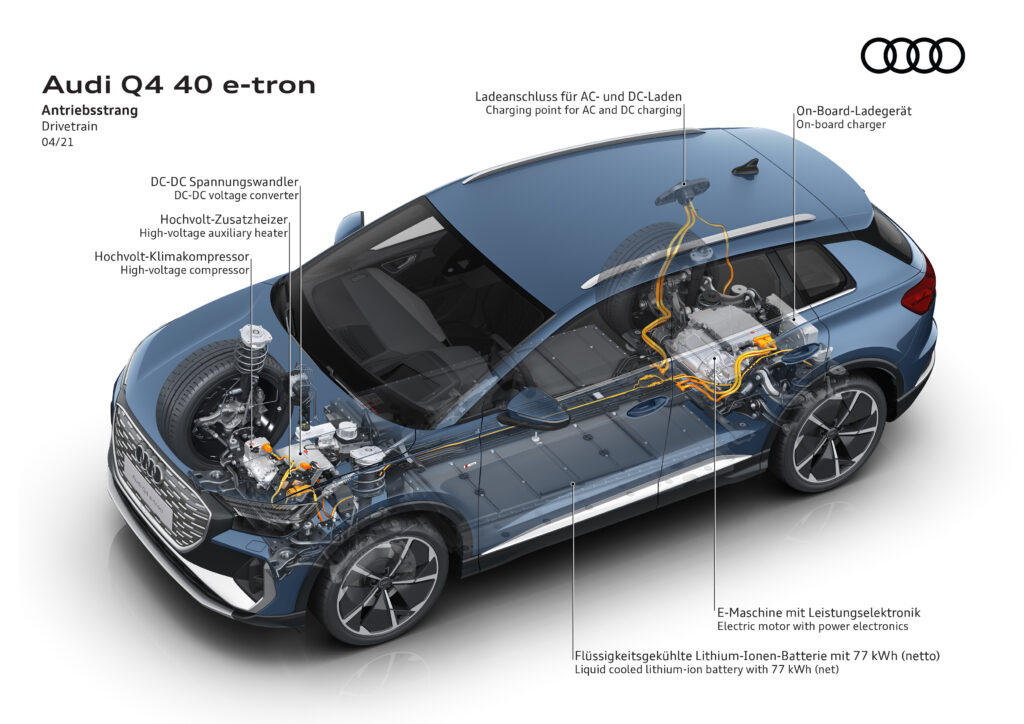

To maintain the ideal battery operating temperature of approximately 30°C, the Q4 is equipped with a thermal management system that utilises a pair of water-glycol coolant circuits.

One circuit regulates the temperature of the motors and supporting electronics and components, while the other circuit is dedicated solely to the traction battery.

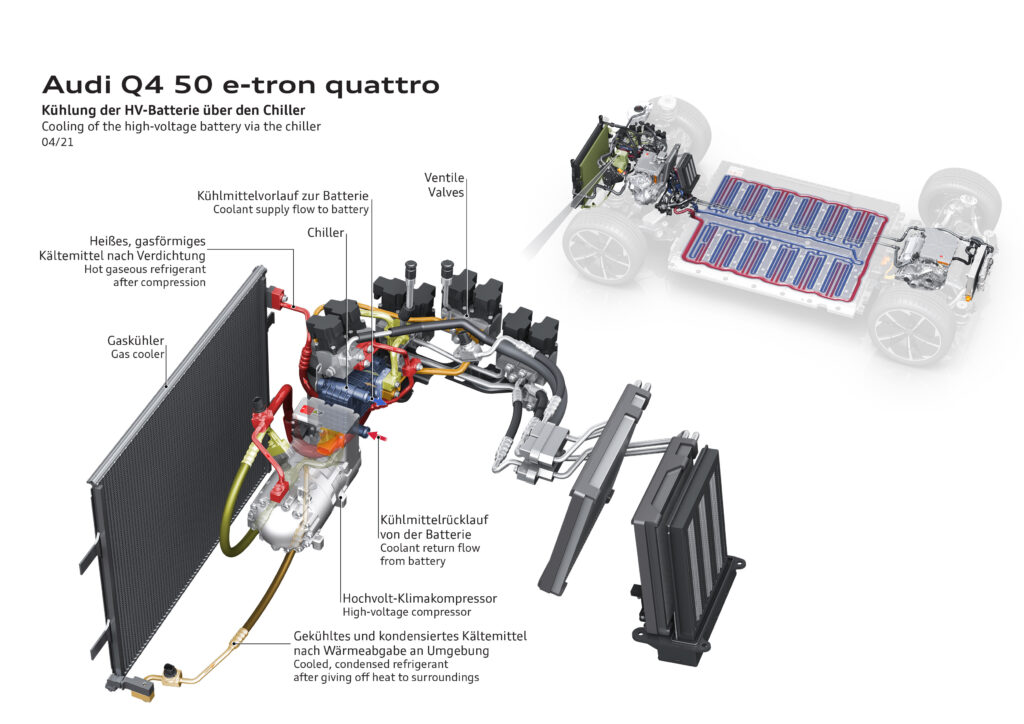

On the underside of the battery is a cooling plate, through which coolant is pumped, and a heat-conducting thermal paste is employed between the cell compartments and cooling plate to ensure effective heat transfer to the coolant.

Removing excess heat from the battery pack is only one of the thermal management system’s roles, though.

To ensure that the battery reaches its optimum temperature quickly, and to maintain that temperature in cold climates, a high-voltage heater is used to warm the coolant and bring the battery up to the ideal operating temperature.

This means that full power will quickly be available from cold starts, as well as ensuring the best battery performance.

Carefully managing the temperature of the battery also delivers the stable thermal conditions required for supporting high-performance driving and high-speed charging without compromising the battery’s lifespan.

All e-tron batteries are warranted for eight years or 160,000 km, after which point Audi says the Q4’s battery should retain at least 70 per cent of its capacity.

The base-grade Q4 has a reputed range of 341km so, potentially, a used example may offer a range of approximately 240km after eight years – but many variables may drive that number in one direction or the other.

Cabin heat in the e-tron is provided, in standard form, by a high-voltage electric air heater. Cooled air, on the other hand, is delivered by an air-conditioning system that uses an electric compressor.

In high-demand driving or charging situations, however, the cooling power of the air conditioning system can be redirected through a coolant chiller, helping keep the powertrain electronics at the right temperature.

Audi offers a heat pump option for the new e-tron as well, which uses waste heat from the powertrain and ambient air to regulate cabin temperature.

The system, which uses environmentally friendly R744 (carbon dioxide) as its refrigerant, reduces the demand for energy-intensive electric resistive heating while also providing air-conditioning to significantly increase the vehicle’s range.

Consequently, it’s an option of notable benefit to those who live in areas with more extreme climates.

As is with many electric cars, customers can remotely operate the climate control system of the Q4 from their smartphone.

If the Audi is plugged in when the pre-conditioned climate option is engaged, power will be drawn from the grid instead of the battery – which, coupled with the reduced initial climate demands once on the move, further helps to improve the range of the vehicle.

The new Q4 e-tron arrives in European markets in June 2021 and, in Germany, prices will start at €41,900 ($A65,900) for the entry-level Q4 35 e-tron.

The basic 1890kg model is rear-wheel drive and features a single 170kW motor that produces 310Nm of torque. Audi claims a 0-100km/h time of 9.0 seconds, a top speed of 160km/h and a claimed range of 341km.

However, more powerful iterations with longer ranges are available. The flagship 2135kg Q4 50 e-tron quattro has a larger battery, two motors and all-wheel drive; Audi claims a peak output of 220kW, 460Nm and a 0-100km/h time of 6.2 seconds. In optimum conditions, the range-topping Q4 can cover 488km on a single charge.

T/CCI launches EV compressor

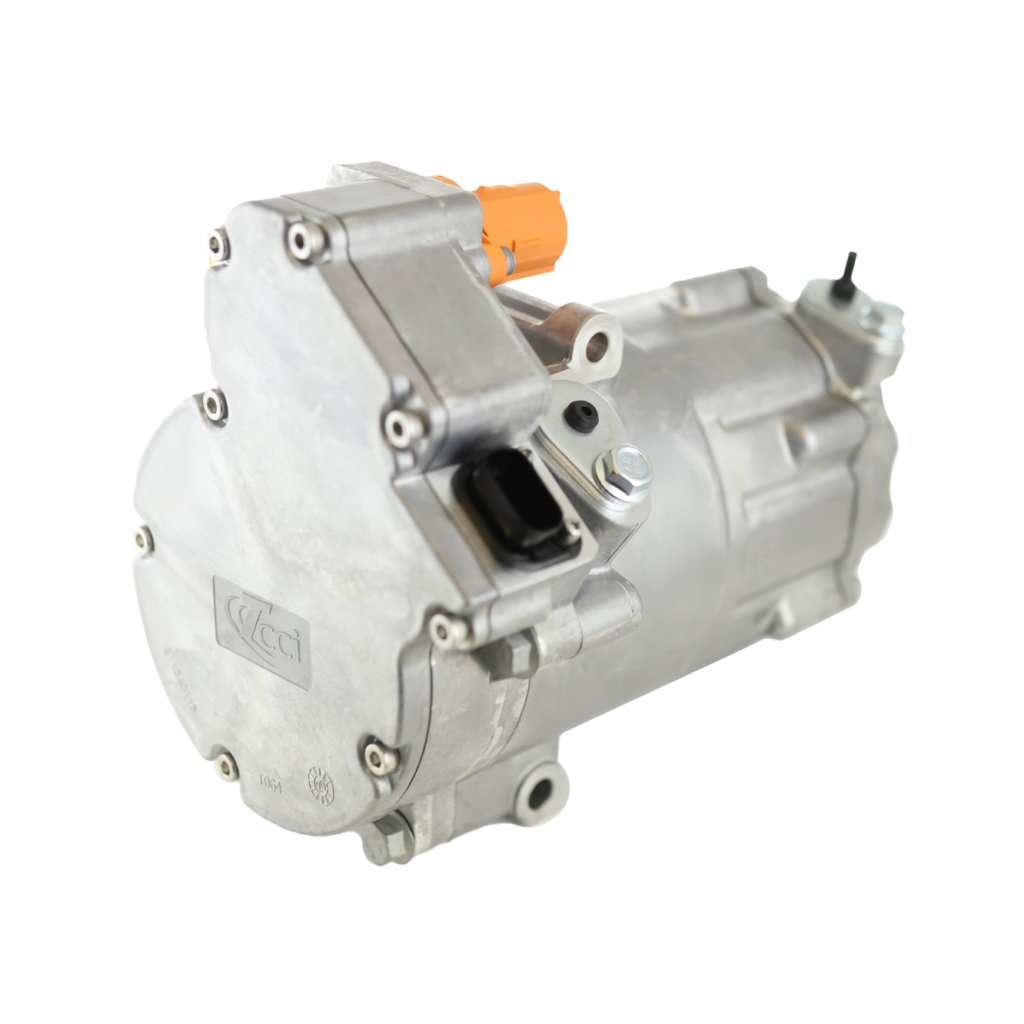

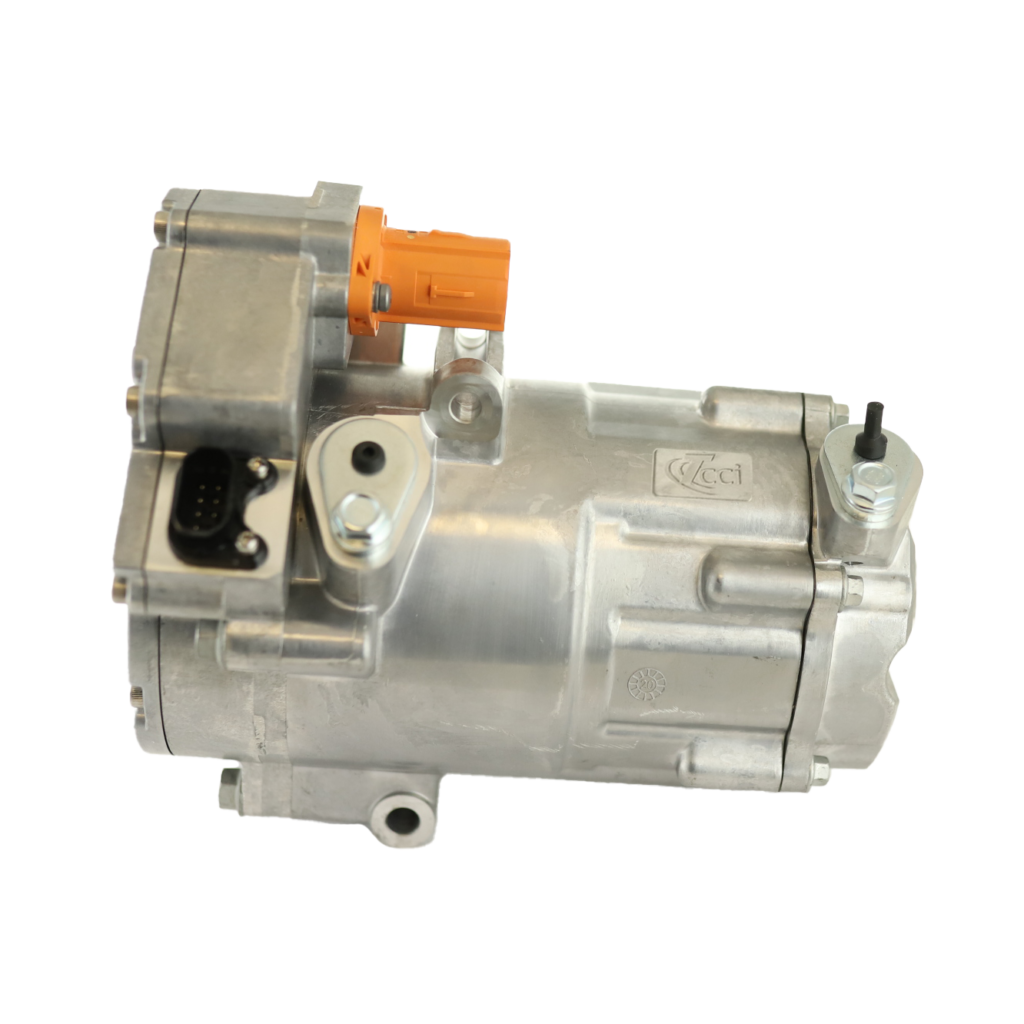

Compressor specialist T/CCI Manufacturing has unveiled electric compressors designed to meet the rising demand for variable electric climate and refrigeration systems.

Its new line-up of compressors are aimed at both low- and high-volume markets, and sectors including automotive, agriculture, trucking, refrigerated transport and public transport.

The scroll-type variable compressors are claimed to be efficient, compact, flexible and easily adapted to different applications. Cooling performance ranges from 2kW to 30kW, the smallest compressor being a 15cc/24V unit and the largest 120cc/850V.

Such displacements might sound unimpressive compared to belt-driven compressors but the two often cannot be directly compared; T/CCI claims its 24cc scroll compressor, turning at 5000rpm, performs similarly to a 150cc piston-based compressor at 1000rpm.

Using electrically driven compressors also offers an array of benefits. No belt drive is required, performance is decoupled from engine speed, cooling can be maintained without engine assistance, and anti-idle laws and emissions targets can be complied with.

The 24-volt options are intended for use in cabin-cooling systems when the vehicle’s engine is turned off. These should prove of considerable appeal to markets where idle times are limited or engines cannot be left running when parked.

A selection of 400V-850V compressors are available for battery cooling systems in more demanding applications. The range-topping 850V compressor, can also be used to provide battery cooling and cabin climate functions in heavy-duty trucking and bus sectors.

Headquartered in Illinois, T/CCI specialises in reciprocating, swash-, wobble-plate and variable compressor designs. It plans to introduce larger electric compressors.

- CategoriesIn SightGlass

- TagsAudi, electric vehicles, EV, heat pump, r744, refrigerant, SightGlass News 24