Bosch slashes diesel NOx emissions

- PostedPublished 9 September 2018

Refined diesel technology to help OEMs meet emissions targets

Bosch has unveiled a series of improvements in diesel emission control systems that dramatically reduce the output of harmful nitrogen oxides (NOx).

Test cars equipped with the new Bosch-developed hardware have, in real-world conditions, emitted as little as 13mg/km of NOx. Currently, a new car in Europe must emit fewer than 168mg/km of NOx in real-world Euro 6 emissions tests. That limit will drop further to 120mg/km in 2020 when revised regulations are introduced.

Even in more challenging conditions, such as heavy city traffic, Bosch’s new system has delivered emissions as low as 40mg/km of NOx. In Australia, for comparison, the emissions regulations are based on old Euro 5 standards and NOx is limited to 180mg/km.

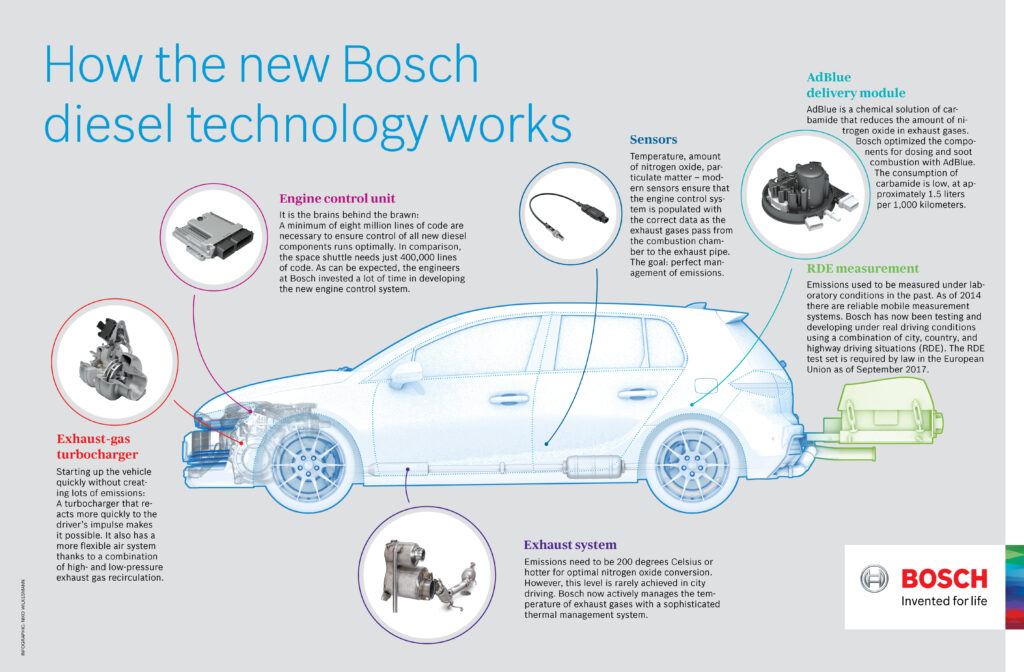

Bosch has achieved this by focusing on two key factors that have previously restricted reductions in NOx emissions – exhaust temperature management and the impact of driving style on exhaust gas recirculation.

In a modern diesel, NOx emissions are reduced by a “Selective Catalytic Reduction” (SCR) catalytic converter, which catalyses the harmful emissions into water vapour and nitrogen. These SCR converters function from 200°C to 550°C, a temperature which is often not achieved in urban conditions; this results in high NOx emissions.

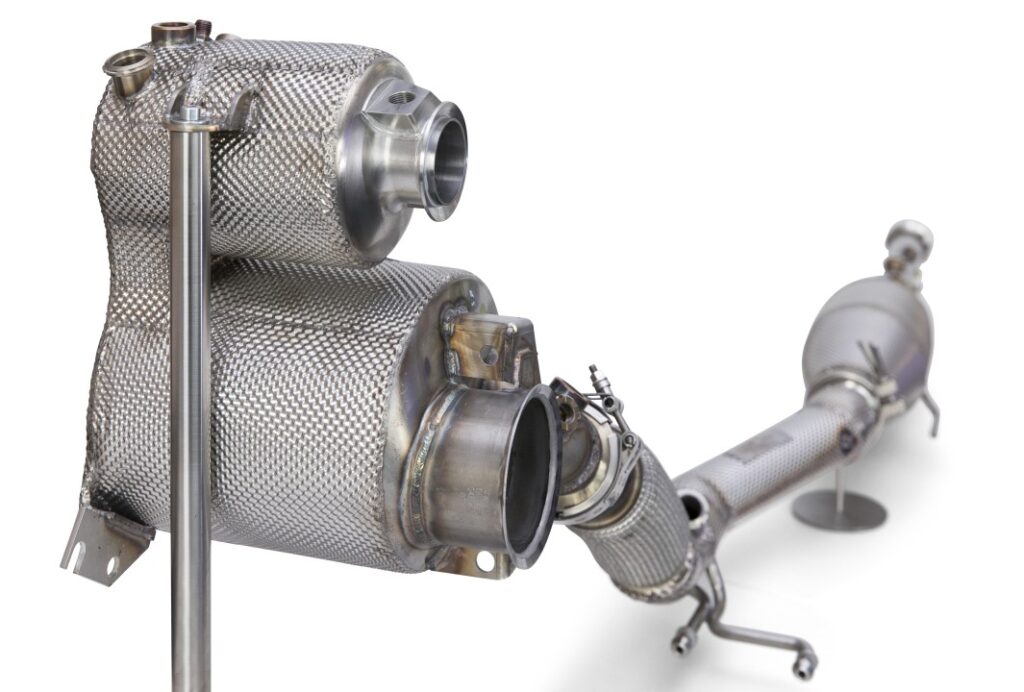

Bosch has tackled this issue with an active thermal management system, which aims to keep the temperature of the exhaust system within the desired range. This is achieved by adjusting variables such as post-injection timing and duration, where fuel is injected late in the combustion cycle to increase the temperature of the exhaust gas when required.

This is coupled with a more responsive turbocharger and low- and high-pressure exhaust gas recirculation (EGR) systems, which help counter the impact of driving style on emissions by more precisely controlling airflow through the engine. NOx is produced when excess nitrogen and oxygen is heated excessively during combustion, so the EGR system recirculates a portion of spent exhaust gases back into the engine. This means less excess oxygen is present in the combustion chamber, helping cut the formation of NOx, and the inert gases also help reduce in-cylinder temperatures.

As Bosch’s set-up can react more quickly, there are fewer spikes in NOx emissions. Bosch has also moved the converters closer to the engine, reducing heat loss, and has worked to improve the sensors and AdBlue injection systems used. As the set-up features no additional components, costs are expected to be the same and Bosch states that customers can begin integrating it with their production projects immediately.

- CategoriesIn SightGlass

- Tagsdiesel, emissions, SightGlass News Issue 14