Can heat pumps prevent potholes?

- PostedPublished 18 December 2023

Researchers at the University of Surrey have developed an innovative solution to tackle the persistent problem of potholes caused by freezing and thawing during the winter, which could significantly improve the state of major roads across Britain.

Potholes are created by three main factors: First, road surface cracks develop due to traffic. Second, water enters these cracks. Lastly, in winter, this water freezes and expands, widening the cracks before eventually thawing. This repeated process weakens the road material, resulting in deterioration.

Previous attempts to prevent road freezing involved embedding heating elements in the roadway, but project leader University of Surrey lecturer at the School of Sustainability, Civil, and Environmental Engineering Benyi Cao sought a more efficient and environmentally friendly approach.

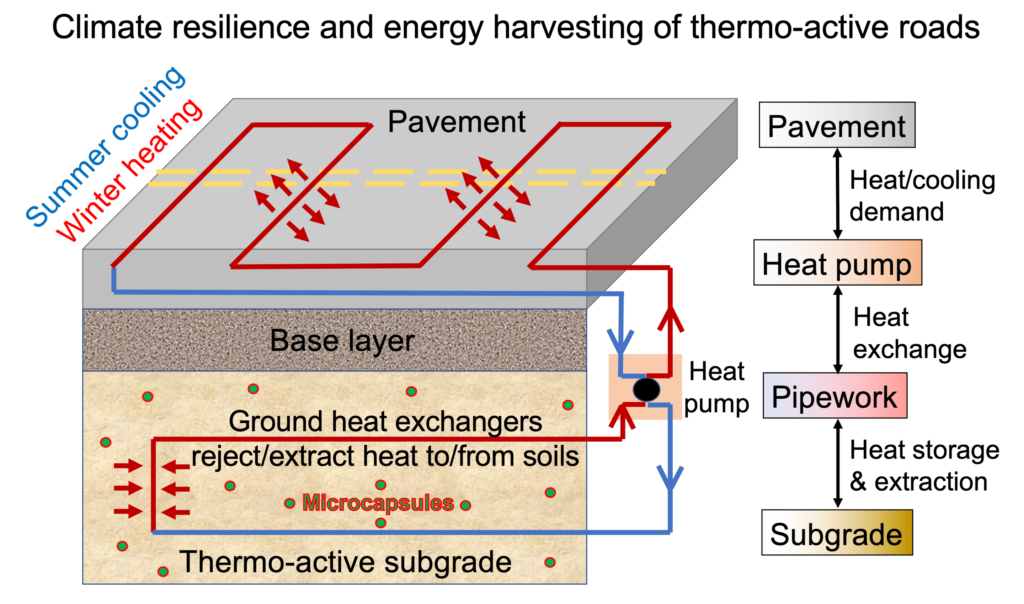

Dr Cao’s idea is to use the ground beneath the road as a heat collector and storage during the summer, extracting that heat during the winter to warm up the surface.

Supported by a substantial A$1.2 million research fellowship from the prestigious Royal Academy of Engineering, Dr Cao’s process involves laying thin plastic pipes across the road during construction, spaced approximately every 5-10 metres.

Additional loops of piping are created underground, around 5-10 metres deep, beside or below the road, surrounded by soil that has been mixed with revolutionary phase-changing microcapsules specifically designed to absorb and release heat.

These surface and underground loops are then connected to a heat pump gently circulating a glycol solution through the loops.

Once a sufficient amount of heat is stored underground, the pumps can be switched off and remain inactive until the road temperature drops slightly above freezing.

According to Dr Cao, a single set of underground coils and a heat pump can likely handle a road segment measuring more than 100 metres in length, and for every unit of electricity consumed by the heat pump, it effectively transfers four units of thermal heat, making it much more energy-efficient than electric road heating systems.

During their five-year research fellowship, Dr Cao and his team will collaborate with British heat transfer material technology specialist Versarien to develop the graphene-enhanced microcapsule.

These capsules will be composed of a phase-change material, such as paraffin or wax, known for its high heat retention capacity; however, to facilitate efficient heat transfer, the shells of the microcapsules will be made from graphite or graphene-based materials. The integration of these microcapsules into the soil during road resurfacing is anticipated to greatly enhance heat conduction and storage capabilities.

To assess the environmental and financial implications of thermo-active roads, Dr. Cao’s team will collaborate with National Highways to conduct field trials and a detailed life cycle assessment. They will also explore the feasibility of gradually implementing this technology during road resurfacing projects.

“At the moment, a typical motorway or A-road surface lasts 20 years, but this is likely to reduce as extreme weather increases. However, by regulating the temperature of road surfaces, they should last significantly longer. Aside from the safety benefits and reduction in car damage, think of the reduction in expensive, inconvenient roadworks,” said Dr Cao.

Repairing potholes in the UK results in 700,000 tonnes of CO2 emissions annually and costs around A$1.3b per year.

Thermo-active roads aim to not only provide a low-carbon and cost-effective alternative, aligning with the UK’s net-zero road maintenance plan, but also provide long-term benefits to drivers and taxpayers.

- CategoriesIn SightGlass

- Tagsheat pump, SightGlass News Issue 31