GM bets the farm on EV, autonomy

- PostedPublished 27 March 2020

Shortly before condemning the Holden brand as unviable, General Motors announced a $US2.2 billion investment that will dedicate its Detroit-Hamtramck assembly plant in Michigan to create its first dedicated production base for electric vehicles.

The company has plans for a “variety of all-electric trucks and SUVs” to be produced at Hamtramck, including a battery-powered pick-up truck that will enter production in late 2021.

Production of the Cruise Origin, an electric, self-driving shared vehicle, will follow “soon” according to GM.

GM president Mark Reuss (pictured above), a former Holden managing director, described the investment as “taking a big step forward in making our vision of an all-electric future a reality”.

“Our electric pick-up will be the first of multiple electric truck variants we will build at Detroit-Hamtramck over the next few years.”

The refurbished plant will source battery cells from GM’s joint venture facility with LG Chem in Lordstown, Ohio, recently announced as a $US2.3b investment in vehicle electrification.

GM says it will plough an additional $US800m into supplier tooling and other projects related to the launch of its new electric trucks.

The Hamtramck plant’s paint and body shops and general assembly area will receive comprehensive upgrades, including new machines, conveyors, controls and tooling.

Currently operating on one shift for production of the Cadillac CT6 and Chevrolet Impala, Hamtramck employs around 900 people. But GM says the upgraded facility will “create more than 2,200 good-paying U.S. manufacturing jobs” once fully operational.

“The support from the state of Michigan was a key element in making this investment possible,” said Mr Reuss.

“This investment helps ensure that Michigan will remain at the epicentre of the global automotive industry as we continue our journey to an electrified future.”

Hamtramck-built Cadillac CT6, Chevrolet Volt plug-in hybrid and Chevrolet Impala models are all being cut from the GM line-up as part of its North American manufacturing restructure.

The Ohio battery cell manufacturing plant will sprout from a greenfield site and create more than 1,100 new jobs, according to GM.

Another goal of the Ohio project is to “develop and produce advanced battery technologies, with the goal of reducing battery costs to industry-leading levels”.

The Origin self-driving car that will be produced at Hamtramck is the product of Cruise, a start-up established in 2013 and acquired by GM in 2016.

Cruise claims the Origin will be able to “cut up to $US5,000 in transportation costs per San Francisco household, per year“.

The company says the Origin will be “affordable” and “comfortable” and “last for more than a million miles”.

GM’s advanced trailer brake

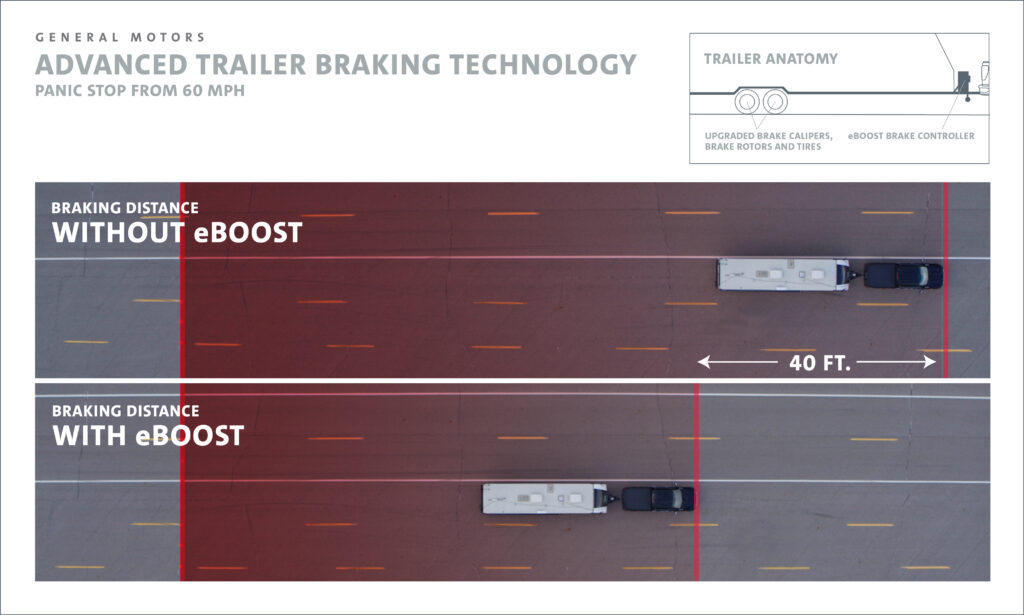

GENERAL Motors has developed an advanced trailer braking concept claimed to drastically reduce stopping distances for vehicles towing a trailer.

The technology is said to provide a vehicle-trailer combination with equivalent emergency stopping distance to the tow vehicle alone, when loaded to its GVM rating.

Helping minimise costs, existing components are used, including GM’s eBoost brake-by-wire system that debuted on the mid-engined C8 Corvette and combines master cylinder, vacuum booster, vacuum pump and electronic brake control module into a single unit.

The 2020 model year Chevrolet Silverado and GMC Sierra pick-up trucks also use GM’s eBoost system, which for the concept demonstration was also replicated on a large 4082kg Jayco caravan that had been additionally fitted with upgraded brake rotors and callipers as well as bigger, better tyres.

Communication between the two eBoost units in tow vehicle and modified caravan was through a regular seven-pin harness, with no additional connections necessary. The system also enabled brake-actuated stability control on the caravan to help reduce sway.

Braking from 96.6km/h, the Sierra test rig and modified caravan combination stopped 20 per cent sooner than they did with the eBoost system deactivated; as quickly as the Sierra would have when loaded to its GVM limit.

GM now plans to work with trailer manufacturers to improve their braking performance and license its eBoost technology to them.

Despite GM pulling out of Australasia, it is conceivable that eBoost technology will come to these shores in imported vehicles that are converted to right-hand drive as is already the case with the Silverado and Sierra.

- CategoriesIn SightGlass

- TagsAutonomous vehicles, electric vehicles, EV, General Motors, SightGlass News Issue 19