Mercedes-Benz dumps R744

- PostedPublished 8 September 2021

It’s official: Mercedes-Benz has confirmed to SightGlass News that it is no longer pursuing carbon dioxide as an automotive refrigerant.

The experience of CoolCar Hamilton with grey import R744 Mercedes models, as featured in Issue 23 of SightGlass News, suggests the systems are problematic.

An inability to cool effectively in hot climates, as experienced by customers in the Middle East who somehow ended up purchasing European-spec Mercedes models with R744, also poses problems for the German luxury carmaker in terms of its ability to deliver warranty cover, not to mention potential damage to its reputation in a key market for high-end vehicles.

While Benz readily confirmed the latest W223 generation S-Class uses R1234yf, it took a bit of coaxing for Benz to say why.

The company’s PR department first tried to dodge the issue by saying it “primarily used the R1234yf refrigerant since 2017 in order to comply with the latest EU regulations”.

When SightGlass News pointed out that R744 also complies, the official line from Mercedes-Benz was: “Due to the fact that the CO2 refrigerant R744 has not yet established itself with conventional drives in the volume segment across all manufacturers, we decided to omit this option in the facelifted current E-Class and the new S-Class model.”

But Mercedes did not rule out a return to R744, saying: “We will closely monitor further developments on the market.”

Meanwhile, Volkswagen Group seems to be persisting with R744 in all-electric vehicles based on its MEB platform, despite official under-bonnet shots of its all-electric ID.3 hatchback clearly showing R1234yf labels.

A Google image search for under-bonnet shots of the ID.3 and other MEB models such as the ID.4 and Skoda Enyaq SUVs reveal a mixture of R744 and R1234yf labels.

The reason for this variation is not known, though it could depend on trim levels, country or whether a heat pump is fitted.

For example, a Munro Live exploration of an ID.4 on YouTube shows a North American market First Edition model with R1234yf labels but a UK market Skoda Enyaq reviewed by Autocar has R744 labels. Both types of label appear in various ID.3 photos published online.

Update from CoolCar Hamilton

Since Issue 23 of SightGlass News was published, repairs to the two R744 Mercedes S-Class models at CoolCar Hamilton have been completed.

The one with a leaking pipe and O-ring at the alloy block was fixed with support from the seller in the UK and the one with a leaking compressor seal was repaired under international warranty, with the compressor and oil supplied by Mercedes-Benz.

CoolCar Hamilton owner, VASA NZ Director Catherine Tocker, said: “Interestingly enough, the fitting instructions included with the new compressor required that the amount of oil in the system be increased.”

Both systems were tested and re-checked for leaks before being handed over to the two customers.

“The owners were very happy with the service they received from CoolCar but not so impressed with Mercedes,” said Catherine.

“The first car had the international warranty thrown out despite the fault being raised with Mercedes within two years of the vehicle being first registered.”

She explained that the fault had been flagged with a Mercedes dealer in the UK at time of export to New Zealand and again with a dealership upon arrival in New Zealand but neither dealer had registered a warranty claim using the proper process.

The car requiring a compressor experienced lengthy delays for parts delivery, with the 250ml of compressor oil coming by sea freight.

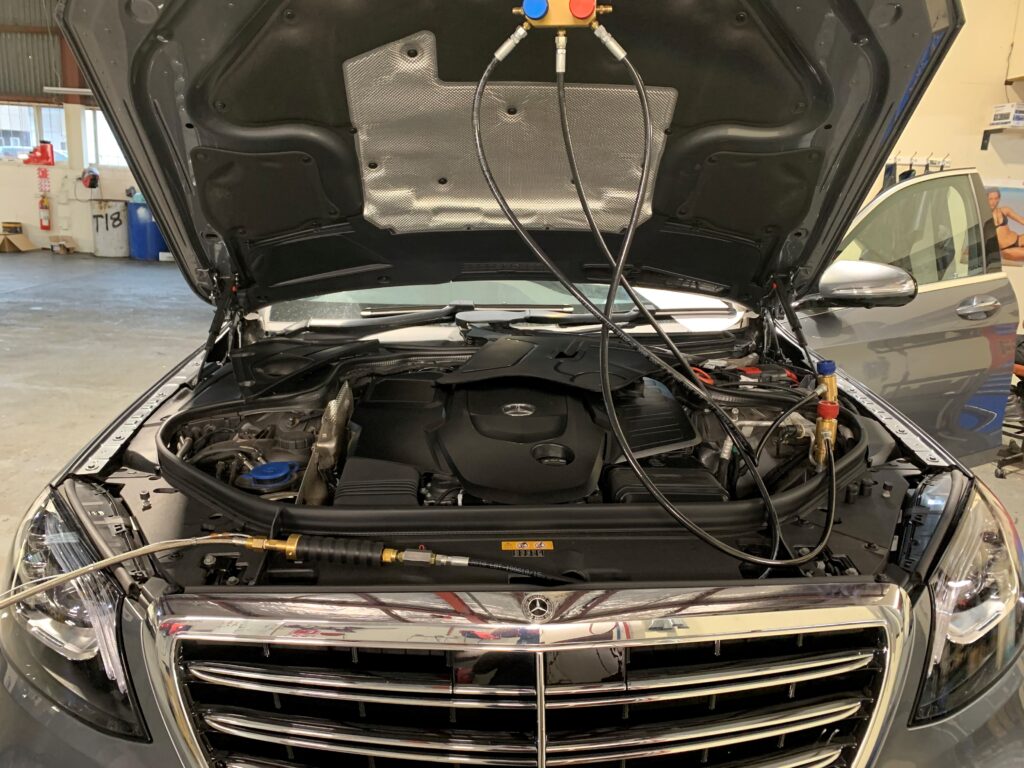

While the R744 Mercedes models were being sorted out, another two cars turned up at CoolCar North Shore 130km away.

CoolCar Hamilton director Rodney Smith transported the R744 gauges, manifold set, refrigerant and leak detector to the North Shore workshop, where the cars were diagnosed.

Neither car had refrigerant and leaks could not be detected using tracer gas in either system because tracer gas pressures do not mimic the operating pressures in R744 systems.

When fully charged with R744 and using appropriate leak detection methods, the grey car (pictured) was found to have a leaking suction hose.

This was confirmed by the presence of oil on the ferrules at the compressor end.

Meanwhile the silver car was found to have a leaking compressor, which leaked audibly from about 500psi once the system was charged.

Neither vehicle was found to be within the Mercedes-Benz international warranty time frame and both were owned by the same (unfortunate) vehicle importer.

One good car was made using donor parts from the other and decisions are being made about how to proceed with repairs to the remaining vehicle, which needs a compressor and a suction hose.

The cost of these repairs is in excess of $NZ10,000.

“This is very much as case of buyer beware,” warned Catherine.

R744 challenges in the workshop

Challenges experienced in working on these R744 vehicles were that the gantry was needed at both workshops to balance the CO2 cylinder on the scales, as refrigerant-grade CO2 is not available for purchase in New Zealand in cylinders smaller than G-size.

To accommodate the size of the cylinder, scales had to be purchased with the highest weight capacity available while allowing for 10g increments and even then, about half of the refrigerant had to be released from the cylinder to get it light enough for the scales to weigh it accurately.

It took a week, every couple of hours, to dump enough refrigerant from the cylinder as the regulator would freeze from the formation of dry ice.

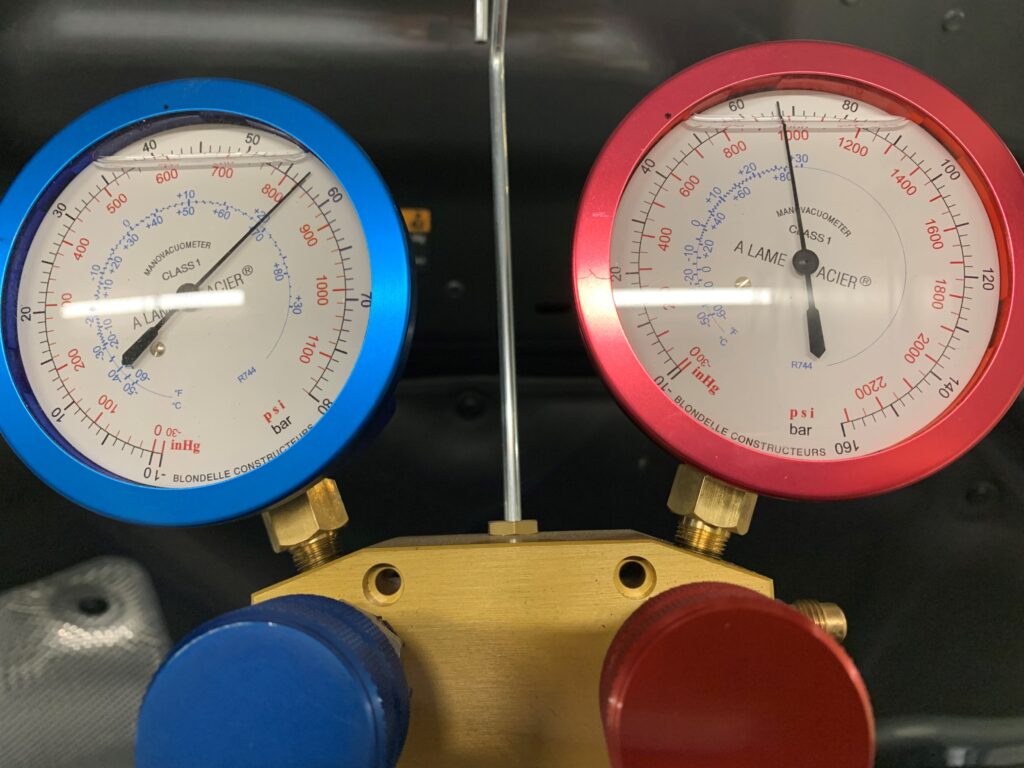

When trying to charge a car, the regulator would only allow 150psi into the system and that the system would not run with to draw the rest of a charge in with just 150psi inside.

Eventually, the charging hose was modified to remove regulator and Cool Car dump-charged the systems with control from the taps at the manifold gauges while another technician stood at the cylinder tap.

This workaround was required under the circumstances and extreme caution was taken.

The quarter-inch BSP fitting on the hand fitting is protected with some thermal covering like Bakelite, to prevent frostbite while handling. There is also a stainless steel wire from the tap through to the quarter-inch BSP hand fitting that could cause severe injury if the hose were to burst or pop off.

Once charged, Cool Car allowed the systems to rest for 10 minutes to get rid of any liquid on the suction side and any frosting that might have occurred.

The next stages were to scan the vehicle to turn on the air-conditioning, then run and test the system.

Note the high static pressures shown on gauges when the system is fully charged.

- CategoriesIn SightGlass

- TagsCO2, Daimler, mercedes-benz, r744, refrigerant, SightGlass News Issue 24