The high-voltage hurdle of humidity

- PostedPublished 1 December 2021

One issue with electric vehicle (EV) battery enclosures is that they cannot be hermetically sealed, because the casing could be damaged by pressure and temperature differentials that arise during operation.

However, this means that condensation can form on the inside of the battery casing – which could lead to electrical shorts and corrosion.

Those issues, to say the least, are ones you want to avoid in your expensive, complicated and warranted battery pack. Condensation can also prove problematic for other electric vehicle components, such as power electronics and charging systems.

As a result, numerous techniques to protect the core components of EVs, and their associated charging infrastructure, are being employed in the battle against water and moisture.

The electric vehicle magazine Charged, in its May/June 2021 issue, documented some of the ways that manufacturers are tackling the matter.

Methods covered included the use of conformal coatings on electronics, the thin polymeric film of which protects components against dust, heat, chemicals and moisture.

Active protection is available in the form of ventilation and heating, but the power required can make them unsuitable. Other passive measures, such as conventional sealing methods and hygroscopic desiccants, can also be employed to protect against damp.

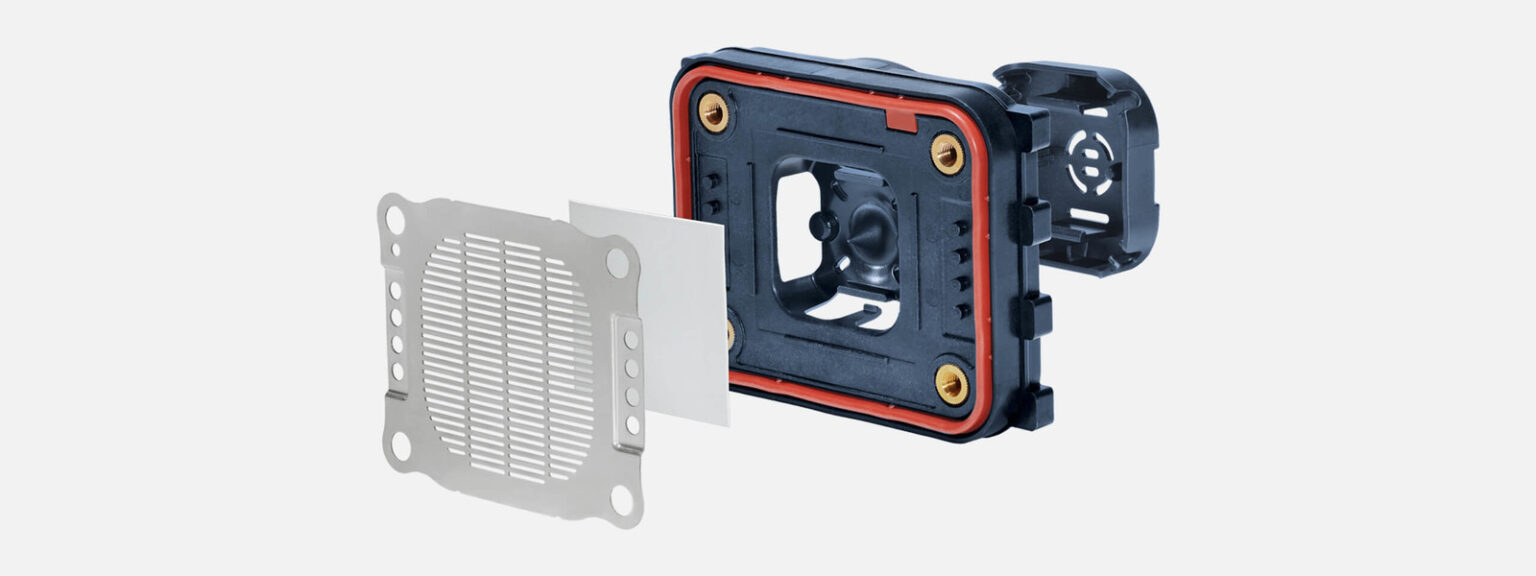

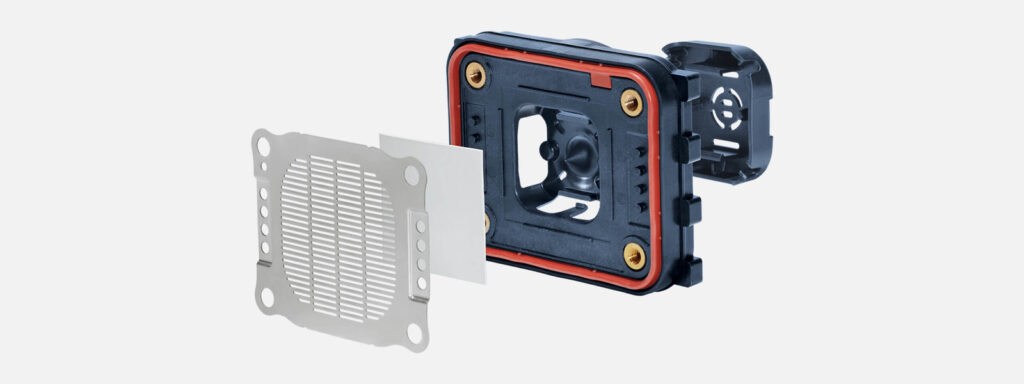

Filter specialist Mann + Hummel, for one, offers reportedly lifetime-lasting dryer cartridges for high-voltage battery systems. These can be used in battery housings, with pressure-equalising vents or breathable membranes, to reduce humidity.

Such techniques, coupled with humidity sensors to trigger ventilation or heating, can be combined to reduce failures, maintenance requirements and power consumption – ensuring each EV has a useful, reliable and effective service life.

- CategoriesIn SightGlass

- TagsSightglass News Issue 25