Toyota and Idemitsu ink solid-state battery partnership

- PostedPublished 1 December 2023

Toyota has partnered with Idemitsu to develop solid-state batteries with a focus on advancing mass production technology for sulphur-solid electrolytes as a promising solution for the future of electric vehicles due to their remarkable energy capacity and power output.

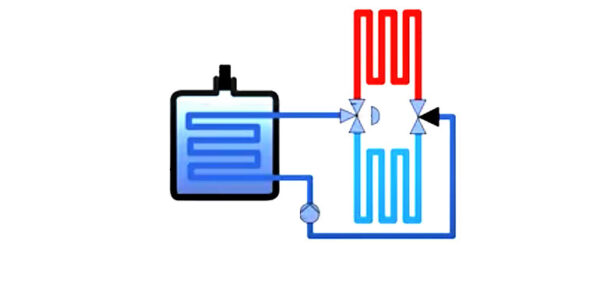

Solid-state batteries, utilising a ceramic-like electrolyte, offer numerous advantages over liquid-electrolyte lithium-ion batteries, including higher energy density, faster charging, and enhanced safety.

These features make them particularly suitable for sports cars and large SUVs, unlocking the full potential of electric vehicles by enabling longer ranges in smaller and lighter packages.

Toyota aims to sell 3.5 million EVs worldwide by 2030, including vehicles from its Lexus brand. To achieve this, the company is developing two versions of all-solid-state batteries.

The first version, expected around 2027–2028, is projected to offer a range of over 1000 kilometres and recharge from 10% to 80% in about 10 minutes. A second version, with a range exceeding 1200 kilometres, is planned for later, addressing consumer concerns about range anxiety and charging time.

Toyota’s battery electric vehicle president Takero Kato, who is in charge of the company’s new Battery Electric Vehicle Factory, expressed his vision in a video posted on the manufacturer’s YouTube channel, stating, “What we want to achieve is to change the future with BEVs.”

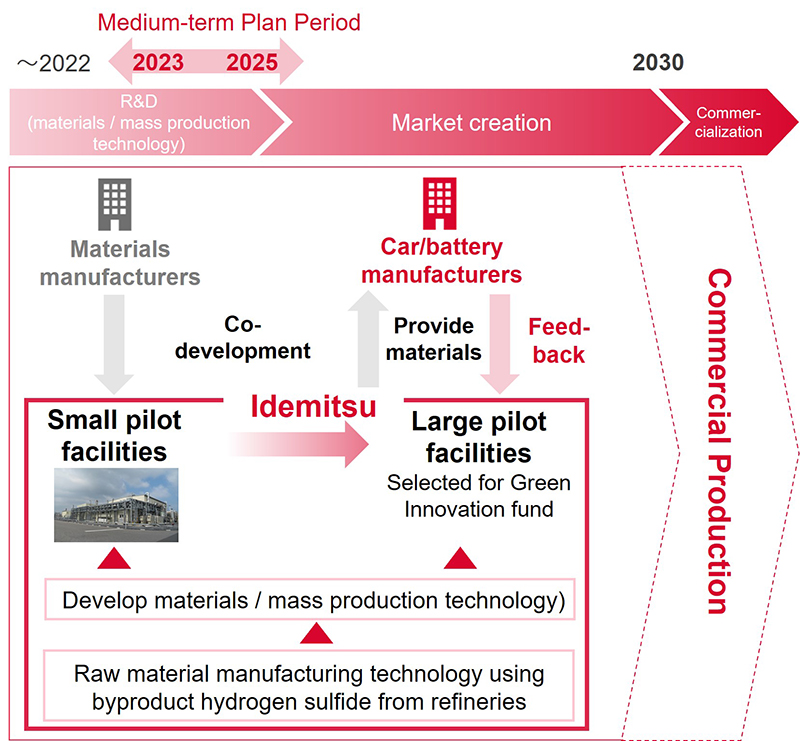

While Toyota initiated its own solid-state battery research in 2006, Idemitsu has been at the forefront of the technology’s development since 2001 and currently operates a small pilot plant specifically designed for producing sulphide-solid electrolytes.

Looking ahead, Idemitsu has ambitious plans to scale up its production capabilities within the next four to five years, ensuring a reliable supply to meet Toyota’s solid-state battery technology program requirements.

Idemitsu President and CEO Shunichi Kito outlined his company’s extensive experience in solid-state battery technology, pointing out that “Idemitsu discovered the usefulness of sulphur components in the mid-1990s”.

“Through our research and technological capabilities cultivated over many years, we have succeeded in creating a solid electrolyte.”

Producing solid-state batteries in large quantities presents challenges, including the assembly process, where cathode-anode cells must be stacked quickly and accurately without damaging the materials.

Toyota has made progress in this area, with a Toyota engineer stating: “In terms of stacking speed, we are almost there. We are preparing to ramp up production and ensure the quality.”

Speaking at a news conference, Toyota President Koji Sato acknowledged the potential limitations in initial production volumes of solid-state batteries but emphasised the significance of prioritising their market release and then gradual volume expansion as the technology advances.

The company intends to establish the inaugural manufacturing line for solid-state batteries near its global headquarters at Toyota City near Nagoya in Japan.

Initial commercial production is projected to cater to a few thousand vehicles, while the planned mass production by 2030 is expected to support slightly over 10,000 vehicles.

Other companies have also made notable progress in this field. Chinese battery maker CATL plans to mass-produce semi-solid batteries by the end of this year, while South Korea’s Samsung SDI has completed a fully automated pilot line for solid-state batteries.

Honda is building a pilot line for solid-state batteries to support its transition to becoming a combustion-free automaker by 2040. Additionally, Nissan plans to invest AU$1.8 billion in the development of solid-state batteries, aiming to introduce them to the market by 2028.

The race to introduce solid-state batteries has the potential to transform the electric vehicle market, their higher energy density and faster charging times seen as essential to overcoming some of the limitations when it comes to EV mass adoption.

- CategoriesIn SightGlass

- Tagselectric vehicles, EV, SightGlass News Issue 32, solid-state battery