Solid-state tech could cut refrigerant woes

- PostedPublished 21 September 2021

One of the long-standing issues with mobile or stationary HVACR equipment, is what happens if and when its refrigerant escapes to atmosphere.

It might be due to a leak, or due to improper disposal of the equipment at the end of its life, but the net outcome is the same – a release of substances that are often harmful to the environment.

While options such as naturally benign carbon dioxide (R744) are available, they’re not suitable for every application.

However, alternatives to systems that use potentially harmful refrigerants and vapour-compression cycles are being developed – such as those using “caloric” cooling, which is being focused on by an international team at the University of Maryland (UMD) in the United States.

Instead of using chemical refrigerant, caloric cooling relies materials that produce a cooling effect when subjected to an external application of stress, strain, electromagnetism or electricity.

Those using mechanical or magnetic forces, respectively known as elastocaloric and magnetocaloric, are of particular interest in the growing field of environmentally friendly cooling.

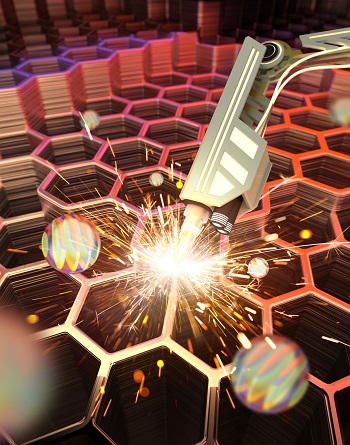

Researchers led by UMD’s materials science and engineering professor Ichiro Takeuchi, for example, have created a durable elastocaloric cooling material, consisting of finely blended and laser-melted nickel and titanium, which can be used in larger devices.

Many other materials are being investigated, too, in an effort to combat the hurdles of cost and fatigue-induced problems that result from the repeated stressing required to develop the desired cooling. “This is a problem when people expect their refrigerators to last for a decade, or longer,” said Takeuchi.

Shape-memory alloys are among the front-runners, as they produce significant elastocaloric cooling, and UMD’s material demonstrated no cooling degradation after one million cycles.

However, many capability, cost- and materials-related hurdles remain – and even magnetocaloric cooling, which was discovered in 1881 and has been revisited over the past four decades, remains limited in its application and use.

Koura previews eco-friendly refrigerant

Fluoroproducts specialist Koura is working on a new refrigerant, called LFR3, which is reputed to have a lower environmental impact than R744 (carbon dioxide).

Naturally occurring R744 is an attractive refrigerant because it has zero ozone depletion potential (ODP) and a global warming potential (GWP) of just one.

While LFR3 has a GWP of 140, it is said to offer higher performance, energy efficiency improvements of up to 20 per cent and operating pressure reductions of 15-20 per cent compared with R744.

Consequently, its life cycle climate performance (LCCP) is potentially slightly lower than R744. LFR3 is also claimed to be non-flammable, further making it suitable for myriad mobile, industrial and commercial applications.

- CategoriesIn SightGlass

- TagsSightglass News Issue 23