US report highlights importance of refrigerant recycling

- PostedPublished 18 September 2015

Australians have known it for years, but it has taken San Francisco based environmental consultancy EOS Climate to alert the rest of the world that refrigerant reclamation and recycling is an important strategy for reducing the impact of high global warming potential gases on Earth’s atmosphere.

“With relatively small changes in practices and little if any additional cost, HFC refrigerants can be recovered, reclaimed and re-used, potentially avoiding emissions the equivalent of 18 billion tons of carbon dioxide (CO2) between now and 2040—a critical window to address climate change,” says the EOS Climate report.

The 18 billion tonnes of CO2 equivalent emissions figure comes from a 30 per cent reclamation rate and is equal to three and a half years of overall greenhouse gas emissions in the US.

According to the report, around 10-15 per cent of HFC refrigerants are recovered, reclaimed and re-used in the United States, although it does not indicate how much is destroyed to avoid emission into the atmosphere at end of life.

Neither does the report mention that Australia’s refrigerant recovery program, operated by Refrigerant Reclaim Australia, is one of the most successful in the world, with up to 61 per cent of refrigerants and synthetic greenhouse gases recovered.

Government-sanctioned recovery schemes are also run in Japan (56 per cent recovery rate) and Europe (Norway has a 40 per cent recovery rate).

To provide an idea of how successful a purely voluntary scheme is by comparison, in New Zealand an estimated 5 per cent of eligible refrigerants are collected for safe disposal – although there is hope this will change with this year’s introduction of a (still voluntary) refrigerant licensing scheme.

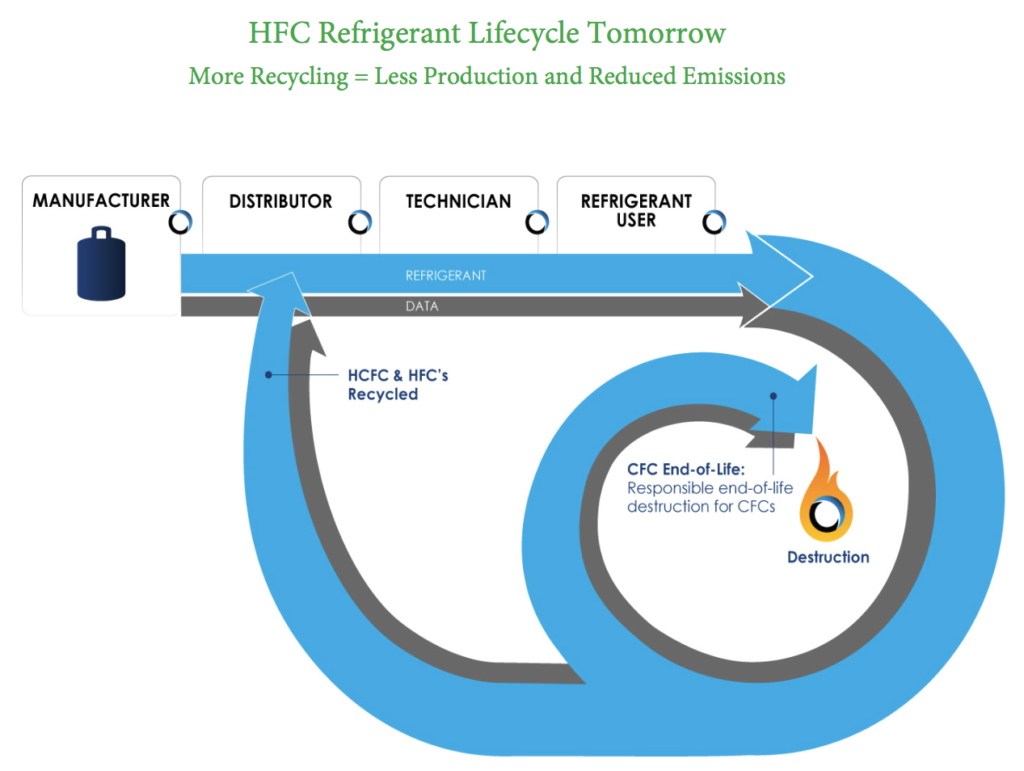

One benefit of the refrigerant recycling – as opposed to destruction – proposed by the EOS Climate report would be maintaining the availability of HFCs in the market to service existing equipment while reducing global production under the proposed HFC phase-down under the Montreal Protocol.

This could reduce the impact of inevitable price increases to HFCs as supply dwindles, reducing the temptation to retrofit HFC equipment with hydrocarbons or undertake other dodgy practices.

However as Australia experienced in the Carbon Tax years, when informal refrigerant recycling became commonplace due to the spike in HFC prices, processes must be put in place to eliminate or at least reduce refrigerant contamination and ensure the purity of reclaimed gas being put back into systems.

Refrigerant contamination with air, hydrocarbons and other substances is now a big problem for the Australian industry and can only be overcome if all people working with refrigerants use an identifier to find out what gases are in the equipment they are servicing before they recover it.

The EOS Climate report concludes: “If left unchecked, HFC refrigerants will continue on the path as the world’s fastest growing greenhouse gas”.

“A simple and cost-effective way to address this problem is through recycling. However, until HFC refrigerants are tracked from production to reuse in the supply chain and metrics are established that incentivise their re-use, the likelihood of voluntary recycling will remain low.”

- CategoriesIn SightGlass

- Tagsrefrigerant, refrigerant reclaim australia, Refrigerant recovery, SightGlass News Issue 3