Victoria AIC gears up

- PostedPublished 10 September 2020

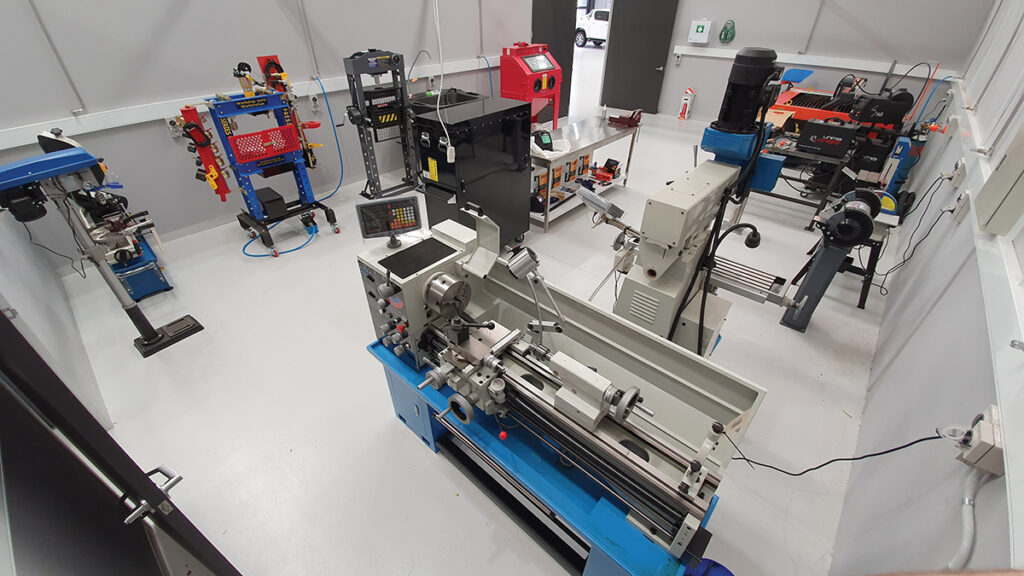

An array of new equipment is to be installed at the Auto Innovation Centre (AIC) to expand its already extensive line-up of services and capabilities.

Upgrades to the AIC, which is based in Melbourne, include a hydraulic test facility that is designed for fatigue and static testing up to 10kN.

“We will also be offering vibration testing with load capacity up to 150kg which can provide high-frequency vibration testing to validate the durability life of components mounted to a vehicle chassis or engine,” said Luke Truskinger, managing director of the AIC.

The AIC will also be getting a new lab-specification tension and compression testing system, with a 10kN capacity and a range of grip and mount solutions.

Truskinger also says that the expansion, which is scheduled by the third quarter of 2020, will include a damper dynamometer that can generate accurate damper plots – even for heavy-duty items used on armoured vehicles.

“It really is an exciting time for all of us here at the AIC and we look forward to offering these new services and continuing to evolve and exceed the expectations of the industry,” said Truskinger.

Operated by the Australian Automotive Aftermarket Association (AAAA), the AIC is designed to support the Australian automotive aftermarket industry.

Among its resources are vehicles, workshops, 3D printing and scanning equipment, dynamic testing facilities and training support.

It also offers services that can be used to demonstrate product compliance with Australian Design Rules (ADRs), which helps aftermarket companies successfully launch new products.

- CategoriesIn SightGlass

- TagsAAAA, AIC, SightGlass News Issue 21