WHAT’S IN THE SYSTEM?

- PostedPublished 10 August 2016

THIS year is the fourth stage in the system testing project started by RRA and VASA in 2013. That first year VASA specialists tested 300 vehicles in State capitals by using refrigerant identifiers.

In 2016 the program was expanded to include regional centres and the number of vehicles tested grew to 500. That’s a pretty fair random sample of the Australian fleet, particularly for vehicles outside warranty. This article considers selected results to highlight the differences between States, and metropolitan and regional centres.

The collective Australian results can be seen in the National Annual Comparison graph (right). As shown, the percentage of vehicles with systems containing 100 per cent R134a has ranged between a high 93.7 down to this year’s result of 84.6. National results can be misleading, as they are not uniform throughout the country. The considerable influence of regional centres is discussed later.

Overall, the major contaminants were air (4.0 per cent) and hydrocarbons (5.6 per cent). Interestingly, only 27 vehicles out of 500 presented with systems devoid of refrigerant. This rather puts paid to the argument made by some less credible industry participants who claim they do not require an ARCtick license because all the systems they work on are empty.

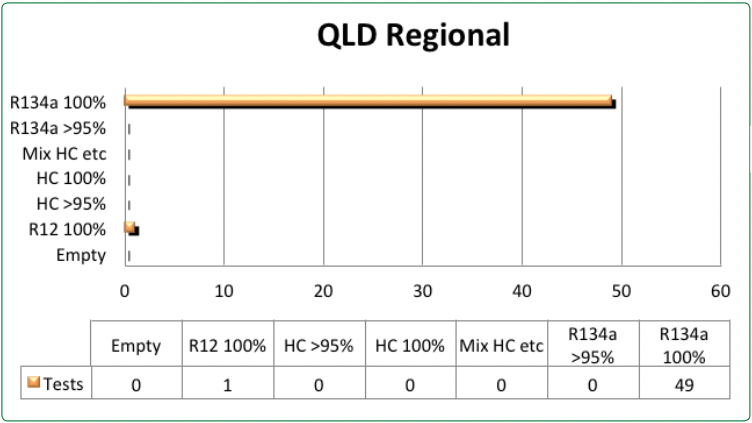

The results become more interesting when viewed by State and locale, so let’s look at the cleanest State first, Queensland.

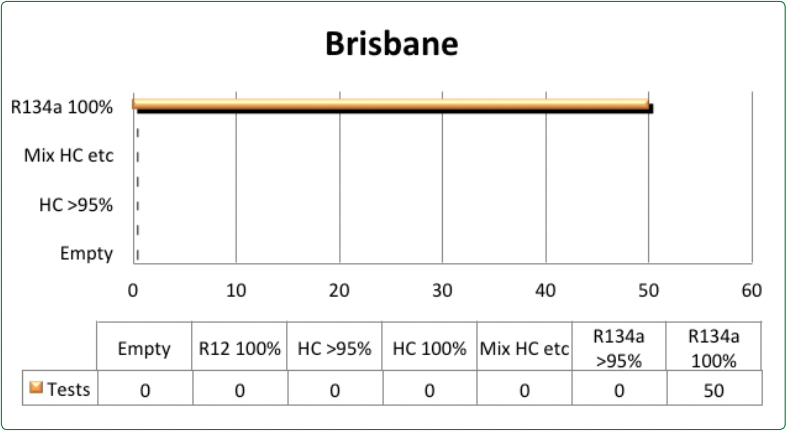

Across the top of this page is Brisbane; the only location that returned 100 per cent R134a in all systems. This should be no surprise as Queensland has regulations that prohibit the installation of non-approved refrigerants in systems without manufacturer and engineering approvals. Even so, it is a remarkable result and useful for comparison with other centres.

The regional Queensland result is almost identical to that of Brisbane with the exception that one vehicle was charged with 100 per cent R12, a truly remarkable result as the last new R12 system was sold in 1995. It’s either the tightest system ever made, or perhaps someone on a property had a cylinder of R12 hidden away and they’ve been topping up their Fairlane ever since.

Results elsewhere aren’t quite so clean.

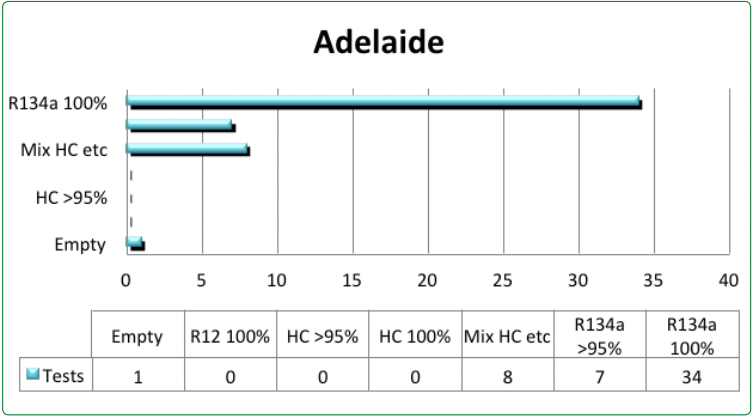

Only 34 vehicles out of 50 contained pure R134a in Adelaide. Seven systems were mostly R134a but contaminated with air. A further eight systems contained mixtures of hydrocarbons and R134a. These mixtures are extremely flammable and should only be recovered with an A3 rated recovery unit, into a cylinder designated and labelled for flammable refrigerant only. These mixtures must be treated exactly the same as if you’re decanting hydrocarbons. If no A3 recovery unit is available (who has one of those?) they must be safely emitted.

But how?

Another project undertaken by RRA in conjunction with VASA and GHD Engineering is looking at the safe emission of flammable refrigerants and mixtures. This will be the subject of another report but in the meantime know that when emitting highly flammable gases it is necessary have a three-metre exclusion zone around the emission point. This means there cannot be any type of ignition source within this space.

The situation in regional Victoria is considerably worse. Here, only half the systems tested contained pure R134a. Five vehicles were filled with R134a and air. Worryingly, ten vehicles, or 20 per cent of those tested, had systems that contained hydrocarbons either mixed with R134a (seven), or pure (three). The highly flammable gases must be handled as described above.

The number of empty vehicles in the regional Victoria results is also an extraordinary result and represents almost 20 per cent of all vehicles that tested empty nationally. While we can speculate, the reason remains a mystery.

So, when examined at the local level, we can see that systems containing 100 per cent R134a range from 100 per cent in Queensland’s capital to just 50 per cent in regional Victoria.

Do you know what’s in the systems you’re working on?

- CategoriesIn SightGlass

- TagsSightGlass News Issue 7