Bugatti reveals how it maintains cabin comfort at more than 400km/h

- PostedPublished 10 September 2020

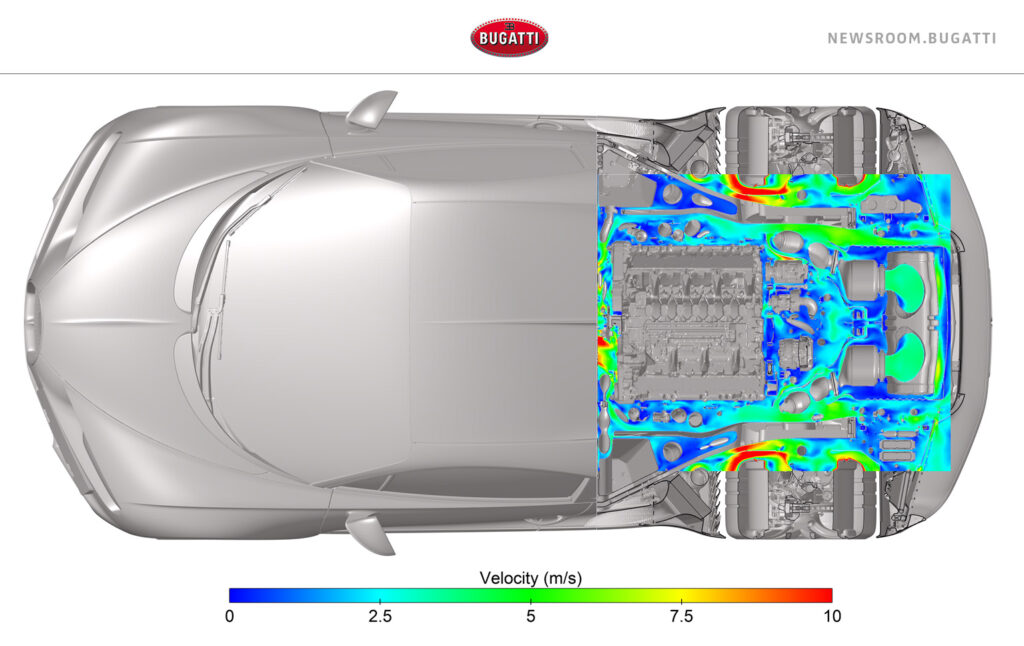

Heat is the nemesis of many a high-performance car. All manner of heat exchangers, ranging from coolant radiators to differential coolers, have to be accommodated and given enough space, airflow and capacity to deal with myriad demanding benchmarks.

And yet, in countless situations, that fine engineering and outstanding capability will often be completely overlooked if the occupants can’t get comfortable and enjoy the experience.

Consequently, adding further challenge to the packaging and heat exchanger nightmare, manufacturers have to ensure that the air-conditioning system in the car functions without fault – even in the most arduous of conditions.

Bugatti, as a case in point, faced a monstrous challenge when developing its 1103kW Chiron hypercar. Four turbochargers, sixteen cylinders, all-wheel drive and an initial claimed top speed of 420km/h all had to be accommodated and achieved while maintaining a comfortable cabin climate.

The company has since pushed the Chiron’s envelope even further, unveiling the faster Super Sport 300+, the driver-focused Pur Sport and the bespoke Divo – and yet, in each, the cabin will remain cool in even hot climates.

“At first glance, our air-conditioning system appears to function like a conventional system,” says Dr Julia Lemke, overall technical coordinator for Bugatti air-conditioning systems, “but it’s a real challenge to perfectly harmonise the highly complex system of a small-series hyper sports car so that it works impeccably even at maximum speed and engine load.”

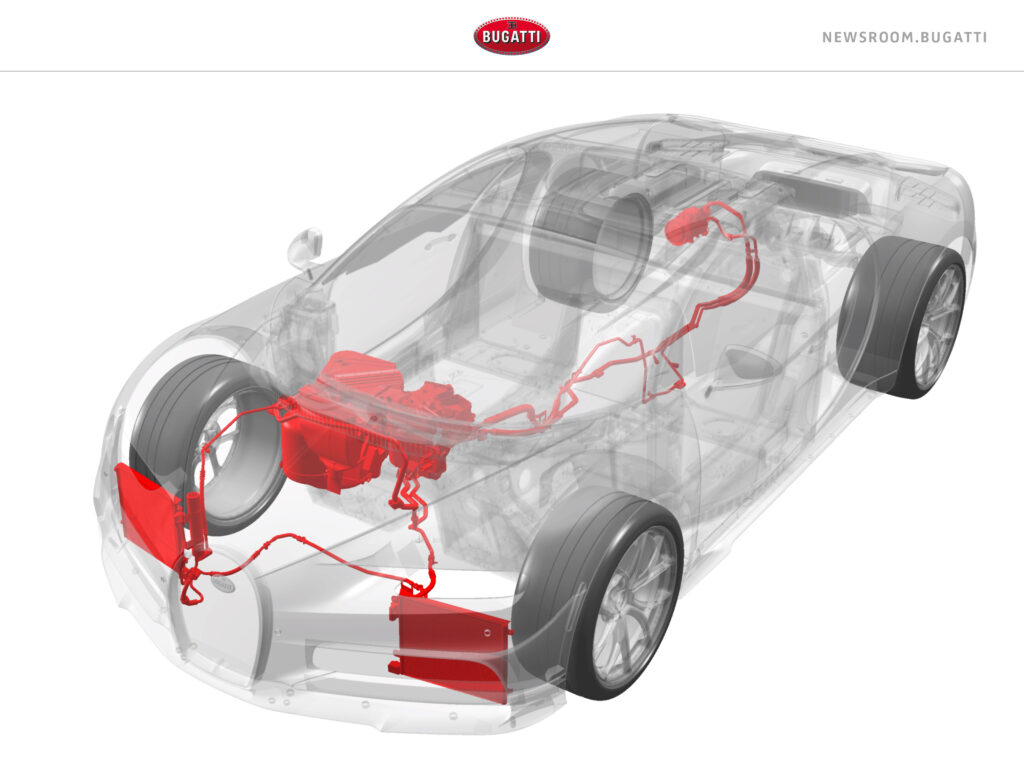

At the heart of the Chiron’s air-conditioning system is an engine-mounted compressor that has a cooling capacity of up to 10kW, which is more than double that of a conventional car. Two nose-mounted condensers dissipate heat from the system, while some 9.5 metres of air-conditioning lines allow 3kg of refrigerant per minute to be moved and compressed from 2.0 bar (29 psi) to up to 30 bar (435 psi).

Reputedly, the system could cool an apartment of roughly 80 square meters in size – granting excellent cooling performance in the Bugatti.

Extensive development was also carried out to ensure efficiency, quiet operation and draught reduction to maximise comfort but, adding yet another challenge, the system also had to be able to maintain its performance at higher speeds.

“Our vehicles travel very fast. In order for the air supply to work properly at maximum speed too, we need to ensure the ventilation and air-conditioning are particularly well controlled,” says Lemke.

Consequently, below 250km/h, the Chiron’s air-conditioning system is fed with high-pressure air from the conventional spot at the lower edge of the windscreen.

Beyond 250km/h, that area changes to negative pressure – so a control system actuates a ram-air flap and bespoke blower motor settings that ensure air continues to enter the system for circulation in the cabin.

The compressor also has to withstand and operate at engine speeds of up to 6900rpm, which entailed extensive development.

“The deeper I get involved as an engineer, the more I admire what is achieved overall in the development of these vehicles,” says Lemke.

“The enormous power of the W16 engine and the incredible speed are unique – this is what makes this highly complex system different from the rest.”

- CategoriesIn SightGlass

- Tagsair-conditioning, Bugatti, hypercar, SightGlass News 21