How to heat and cool an EV bus

- PostedPublished 30 June 2019

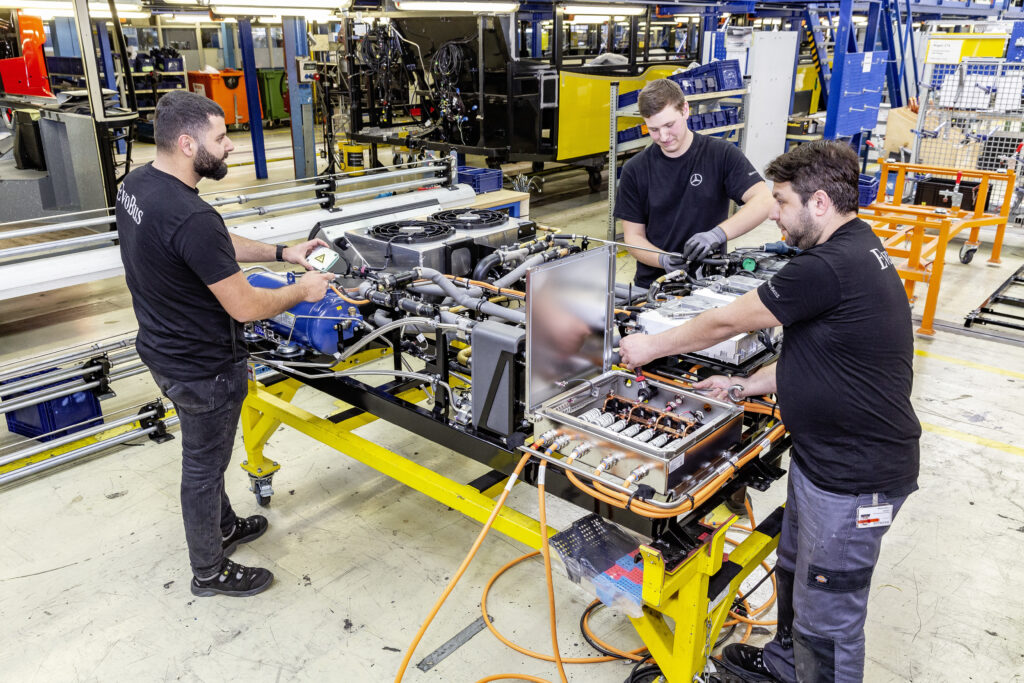

Mercedes engineers grapple with passenger comfort for eCitaro bus

Keeping bus interiors at the right temperature is a substantial task at the best of times, considering the huge internal volume, large glass area, frequent door-openings and constantly changing passenger loads.

According to Mercedes-Benz, the overall energy consumption of a city bus doubles at -10°C compared with journeys on which no heating is required.

This means that for electric city buses, energy consumption rather than battery capacity is the true indicator of performance and range potential.

As one of many manufacturers now developing electric buses, Mercedes has set about addressing the efficiency impacts of thermal management.

R744 (carbon dioxide as a refrigerant) is central to its strategy, which ended up reducing HVAC energy requirements of the eCitaro electric bus by around 40 per cent compared with the diesel equivalent.

“This is accomplished with the use of innovative components that only reached market readiness in line with the eCitaro,” says the Mercedes press release.

First and foremost, the eCitaro thermally manages its battery packs to ensure they remain at optimum temperatures for maximum charging capacity, performance capability and service life.

This includes using the passenger-compartment climate control system to provide additional battery cooling in extremely hot conditions.

In addition, heat-producing components are linked together, to minimise the energy needed to keep them cool.

Passenger compartment heating is via an energy-efficient heat pump, distributed using familiar sidewall fan heaters, while a conventional heater at the front uses a double heat exchanger.

When it’s really cold outside, the roof-mounted air-conditioning system provides extra passenger compartment warmth by functioning as a second heat pump.

“The use of CO2 as a coolant brings further benefits,” says the press release.

“The particularly efficient use of the heat pump is impressive, even at very cold temperatures.”

Accounting for the amount of heat given off by the human body, the eCitaro intelligently varies the output of the heating and climate control systems according to the number of passengers.

While plugged in for charging, the eCitaro can also be pre-heated or cooled to suit outside conditions before it sets off.

In mild weather, the eCitaro’s operational range is about 170km, which Mercedes says is sufficient for around a third of all bus routes.

Why buses are going electric

A STUDY of 75 heavy-duty public transport buses conducted in Beijing revealed that diesel-hybrid buses were particularly sensitive to air-conditioning use, causing fuel consumption to increase by up to 50 per cent and largely offsetting the fuel-saving potential of hybrid technology.

As a reference point, the study found the average fuel consumption of diesel buses to be 32.6 litres per 100km.

For these reasons, buses have been singled out as a prime target for full electrification. The Chinese city of Shenzhen, for example, has switched all 16,000 buses in its fleet to pure electric – along with most taxis.

The majority of these vehicles are made by Shenzhen-headquartered EV specialist BYD, in which US investor Warren Buffett’s Berkshire Hathaway company has a 25 per cent stake.

Aussie electric bus

AUSTRALIAN bus builder Volgren will launch an electric bus this August following trials of a prototype that was nearing completion as we went to press.

The prototype is built on a BYD chassis, with a 324kWh battery capacity providing more than 250km of operational range.

Volgren business development manager Jon Tozer said the company had been investigating electric vehicles for more than five years and that the prototype was 12 months in the making.

“We’ve known for some time that the bus industry was about to go through its biggest transformation in three or four decades,” he said.

“In the case of this first electric bus, we wanted to ensure that we built on a known quantity. We didn’t want to conduct a science experiment or work with a conglomerate of part suppliers attempting to provide a solution. We wanted something that will work from the start.”

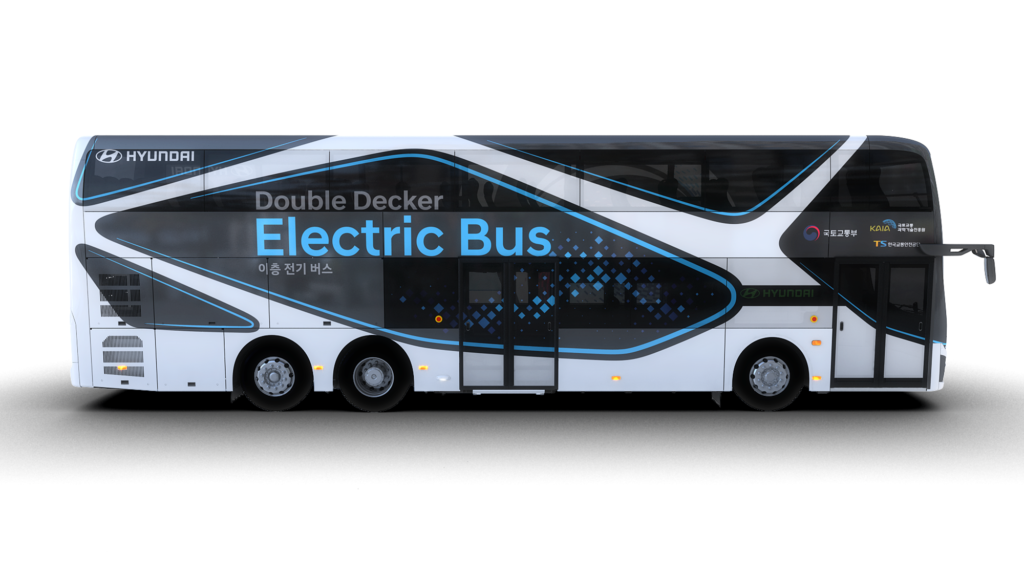

Hyundai’s electric double-decker bus

HYUNDAI revealed an electric double-decker bus at the recent Land, Infrastructure and Transport Technology Fair in South Korea, the culmination of an 18-month project backed by the nation’s Land, Infrastructure and Transport Ministry.

Power comes from a 384kWh water-cooled lithium polymer battery that provides up to 300 km of operational range.

Significantly, a full charge can be completed in just 72 minutes.

The 70-seater bus – 11 seats downstairs and 59 seats on the top floor – also accommodates two wheelchairs and is equipped with an automatic sliding ramp.

A low floor design helps improves accessibility for disabled and mobility impaired passengers.

For the driver, Hyundai’s double-decker packs a 240kW drive motor, rear-wheel steering and safety assist features including forward collision warning with autonomous emergency braking, lane-keep assistance and electronic stability control.

Hyundai Motor’s head of commercial vehicle advanced engineering ByoungWoo Hwang said the electric bus “will not only ultimately improve the air quality, but also contribute greatly to easing commuting hour traffic congestion by accommodating more passengers”.

Even Cummins is going EV

SYNONYMOUS with diesel since licensing a compression-ignition engine design from R.M. Hvid 100 years ago, Cummins is nevertheless embracing the electrification era.

The most recent example of this wholehearted shift is the Gillig battery-powered bus that was unveiled at the recent American Public Transportation Association Bus and Paratransit Mobility Conference in Louisville, Kentucky.

With a 444kWh battery and 38-passenger seating capacity, the zero-emission bus will now embark on a tour across the United States so that transport operators can trial it on existing routes.

Its electrified Cummins drivetrain comes with remote diagnostics and over-the-air connectivity as well as access to the Cummins support network and service training programs.

The Gillig electric bus was four years in the making. Speaking at a customer preview event at Gillig’s Livermore production facility and headquarters in California, company president and CEO Derek Maunus said that using Cummins technology for its electric buses “enables us to offer our customers an unmatched nationwide service and support network”.

In addition to transit buses, Cummins provides electrification technologies for school buses and trucks, including plug-in hybrid systems.

The company has developed a scalable battery architecture for small and large commercial applications with cross-flow cooling and thermal control to keep the batteries within their optimum operating temperature range of 23-27°C.

Other recent applications of Cummins electric drivetrain tech include a prototype mini excavator, a fleet trial of eight electric vans for the US Postal Service in California and a collaboration with Kalmar to produce electric terminal tractors for the European shipping industry.

As part of its $US500 million investment in electrification, Cummins employs 200 engineers that it says are “solely focused on inventing electrified power solutions”.

- CategoriesIn SightGlass

- Tagselectric bus, electric vehicles, EV, SightGlass News Issue 17