Secondary loop auto-AC trial results

- PostedPublished 30 June 2019

Greater efficiency from a smaller refrigerant charge

Successful trials of a secondary loop car air-conditioning system could open the door to a range of alternative refrigerants with smaller charge sizes.

Potential benefits to the consumer include improved fuel efficiency and lower servicing costs.

As a global average, energy consumption by car air-conditioning is estimated at between 3 and 7 per cent, rising to almost 20 per cent when hot and humid climates are combined with traffic congestion.

These conditions can also reduce electric vehicle battery range by 30-50 per cent.

R152a has been identified as superior to R134a in terms of energy efficiency and global warming potential (its GWP of 138 is around a tenth of R134a), reducing both direct and indirect emissions.

But as an A2-rated flammable HFC, adoption of R152a by the global automotive sector has been hampered by safety concerns, hence the switch to the mildly flammable A2L R1234yf and, to a lesser extent, R744 (carbon dioxide).

With a hot, humid climate and heavy traffic congestion an everyday reality in its home market of India, automotive manufacturer Tata Motors is well placed to initiate development of secondary-loop AC systems using R152a.

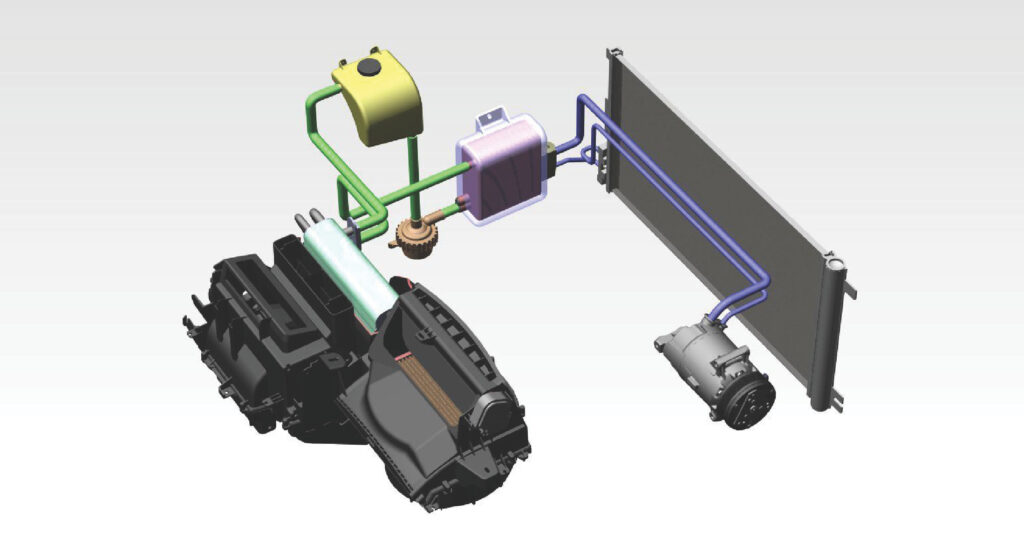

In collaboration with the Institute for Governance and Sustainable Development and Mahle Behr Troy (formerly known as Delphi), Tata had its three-row Aria people-mover converted to run a secondary loop AC system by Mahle in the United States before shipping it back to India for tests in local conditions.

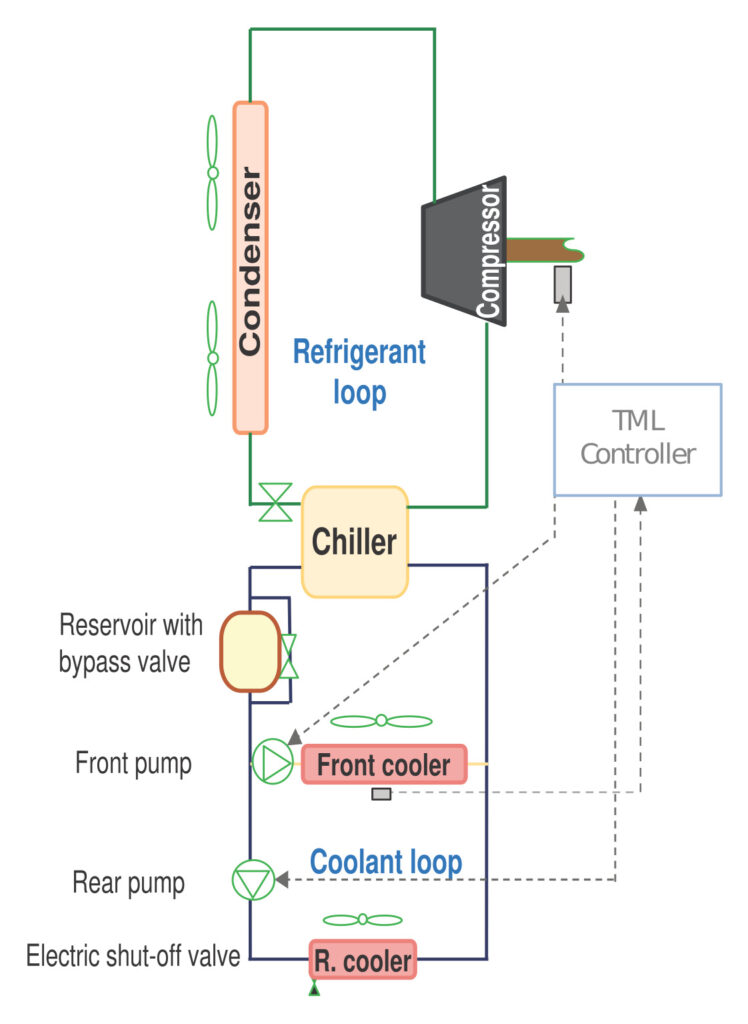

Engineers aimed to reduce refrigerant charge size in the secondary loop system by at least 40 per cent compared with the conventional direct expansion layout it replaced, enabled by both the shorter refrigerant hoses and refrigerants’ qualities.

To achieve important fuel savings, the compressor control logic was modified to ensure the air-conditioning only operated when is it was most efficient to do so, using the built-in thermal reservoir of chilled coolant to maintain cabin temperatures when the compressor was idle.

A target of similar average cabin temperatures as achieved by the Aria’s standard R134a direct expansion system was missed, but engineers concluded that further development of the prototype secondary loop system could improve cooling performance.

R1234yf was also assessed in the secondary loop setup, but R152a demonstrated superior performance in the challenging Indian conditions.

The vehicle using R152a was between 1.9 and 2.6 per cent more fuel-efficient than the direct expansion R134a system on the India Drive Cycle.

Due to R152a’s lower GWP and a charge size half that of R134a used in a direct expansion system, direct CO2 equivalent emissions were calculated as at least 95 per cent lower when using R152a in the secondary loop setup.

From a consumer standpoint, the engineers expected a commercialised secondary loop system using R152a would save vehicle owners money on both fuel and servicing.

In addition to require half as many services as a direct expansion R134a system, a secondary loop R152a system is expected reduce fuel use by 20-40 litres per year depending on driving habits and air-conditioning usage.

That’s more than a tonne of potential CO2 emissions over a vehicle’s 10-year lifecycle, with even greater fuel savings possible when using secondary loop on vehicles with idle-stop technology.

Secondary loop benefits

Because only a glycol solution enters the passenger compartment, a greater choice of refrigerants is available to system designers. Still, the engineers opted for R152a over a hydrocarbon.

The likelihood of refrigerant leaks is reduced due to fewer fittings and shorter refrigerant lines.

In vehicles with idle-stop technology, the reservoir of chilled coolant could provide around two minutes of cabin comfort before restarting the engine to drive the compressor.

R152a vs. R1234yf

The engineers’ report provided a side-by-side comparison of the prototype secondary loop system used with both R152a and R1234yf.

Interestingly, the much lower price of R152a more than offset the manufacturing requirement costs of a secondary loop system layout, compared with R1234yf in a conventional direct expansion setup.

According to the report, a secondary loop system using R152a costs $36 more to manufacture than a direct expansion R134a system, while an R1234yf direct expansion system is $65 costlier.

Using R1234yf in a secondary loop system costs only $6 more than for direct expansion because the charge size is 34 per cent smaller, demonstrating the impact of high R1234yf prices.

With R152a, an even smaller charge size was used, while outperforming R1234yf with lower cabin temperatures at 35̊C and 45̊C ambient and significantly reducing power consumption at the compressor (R1234yf increased consumption).

However, engineers admit that installing an internal heat exchanger as used in almost all R1234yf direct expansion systems would help level the playing field.

Secondary loop a viable option

Overall, the results of this exercise validated the engineers’ theory that low-GWP refrigerants used in a secondary loop car air-conditioning system could benefit both climate and consumers compared with a conventional R134a system.

The study also showed that secondary loop system using R152a could provide car manufacturers with a viable and cost-effective alternative to R1234yf.

Read more:

- CategoriesIn SightGlass

- TagsFlammable refrigerants, R1234yf, R134a, R152a, refrigerant, secondary loop, SightGlass News Issue 17