R1234yf ‘really close’ to perfect

- PostedPublished 14 June 2015

But even mild flammability made industry acceptance a hard sell

A leading engineer behind the development of new industry standard automotive refrigerant R1234yf concedes that flammability is its biggest drawback – but that apart from that it is close to being the perfect gas for car air conditioning systems.

During an exclusive interview with SightGlass News at VASA’s Wire & Gas convention, Barbara H Minor revealed the fascinating process behind finding a replacement for R134a, which faces a global phase-down due to a high global warming potential (GWP) rating of 1300.

Dr Minor, who is senior engineering fellow at Chermours (a subsidiary of DuPont in the USA), said three main priorities for developing the new refrigerant were a GWP below 150, non-flammability and high efficiency.

Performance properties similar to R134a were also desirable, to keep air conditioning system design changes – and therefore costs – to a minimum for component and vehicle manufacturers.

“The biggest challenge (of the R1234yf project) ended up being industry acceptance of the flammability,” said Dr Minor.

“A lot of work done under SAE to evaluate the flammability, years of study, and then Daimler questioning the flammability instigated a lot more study to double-check the flammability – that was certainly the biggest obstacle, to demonstrate that safeness.”

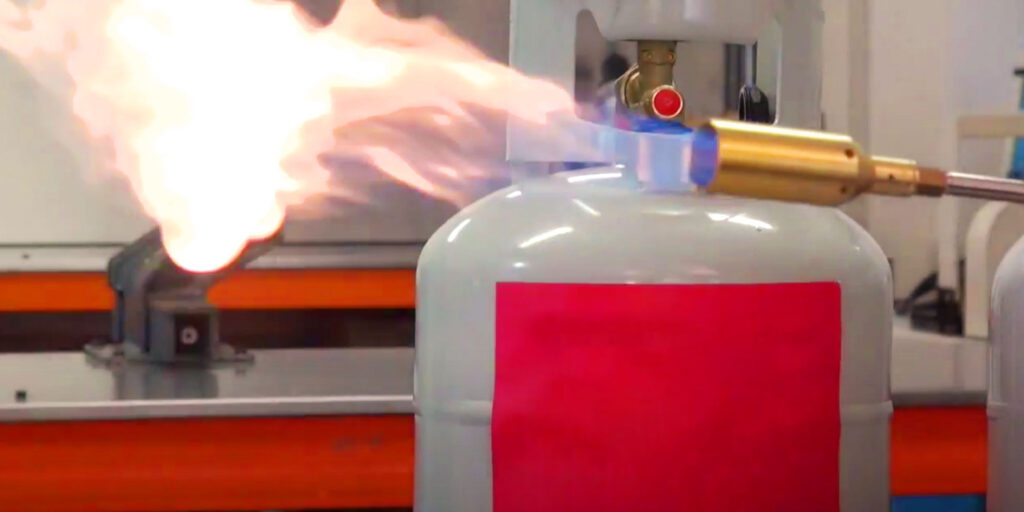

During the development and commercialisation of R1234yf, many kinds of groundbreaking flammability testing had to be conducted.

“It was a whole new area,” explained Dr Minor. “How do you test an air conditioning system in a car and demonstrate that flammability is not going to be a problem?”

Asked how close R1234yf was to being the perfect automotive refrigerant, Dr Minor said “it is really close – if it wasn’t flammable … but there’s low toxicity and there’s always a challenge with toxicity hurdles when you test a refrigerant”.

In addition to the controversy surrounding the flammability of R1234yf, concerns have been voiced about harmful byproducts such as hydrogen fluoride being released if it is burnt or exposed to extreme heat, but Dr Minor dismissed those claims.

“Part of the evaluations of the SAE (Society of Automotive Engineers) was taking a look at the decomposition product and one of the things you look at is the structure of R134a compared to R1234yf,” she said.

“They both have four fluorines, they both have two hydrogens. R134a I would say is non-flammable but it is very close to that border of being flammable. If you have a full-blown car fire and you release either of those refrigerants, you’re going to create the same toxic byproducts.

“In all the 20-year history of R134a there have been no reported incidents of anyone having any exposure issues from R134a in a car fire. So we don’t expect any difference with R1234yf.”

Asked whether there was a chance that another refrigerant – other than CO2 as being developed by some German manufacturers – was likely to appear, Dr Minor was pretty confident that R1234yf is here to stay.

“I don’t see a successor on the horizon because we did very exhaustive studies of all the different molecules and any options were going to be more flammable, so you’ll have that challenge or more likely will have challenges addressing toxicity in the chemical structure.”

On the work that went into minimising the flammability of R1234yf, Dr Minor said the process involved looking at potential molecules and a boiling point range to work within, then adding fluorine to the molecule in order to reduce the flammability as much as possible.

“Once you’ve created the molecule the flammability is what it is, you can’t do anything to change it,” she said.

In fact, flammability and low GWP do not have to come together – Dr Minor’s team is in the process of commercialising another, non-flammable, HFO refrigerant with a GWP of around 9 but is unsuitable as an R134a replacement due to its high boiling point.

“Just because something is an HFO doesn’t mean it has to be flammable,” she said.

R1234yf origins

When asked about the origins of R1234yf, Dr Minor revealed that only the chemical structure and approximate boiling point were known when the project began.

“It had never been commercialised before, never made on a large scale before,” she said.

Part of determining what the R134a replacement should be like was consulting with component and vehicle manufacturers, who laid out their design criteria and preferred parameters. But when Dr Minor’s team started investigating molecules it became clear their options were limited.

“It’s very hard to find a low GWP that meets at least a couple of the criteria, so it was a question of trade-offs and balancing all the properties,” she said.

“The real breakthrough was in determining that adding the double-bond, making it an olefin, dramatically reduced the GWP. That’s what I think really pointed the research that DuPont and Honeywell were doing jointly to look at the olefin family and see what we could find within that family.”

At the development stage it was impossible for the engineers to know what GWP the final product would end up with, and Dr Minor admitted she was surprised by the result.

“I didn’t expect it to be so low. I also think that early in the 1990s olefin families were known but were perhaps considered to be too unstable or have some toxicity issues – so back when they were considering all the families to replace CFCs the HFCs were a much safer bet.”

Pouring cold water on hydrocarbon claims

In Australia, New Zealand and some developing countries, hydrocarbon refrigerants are marketed as a ‘drop-in’ replacement for R134a and R12 systems but the SAE, which conducted exhaustive testing on flammable R134a replacements like R1234yf and R152a, is unlikely to agree.

For example, the SAE specifies that R1234yf systems must minimise the chance of refrigerant leaking into the passenger compartment with safeguards like a more robust evaporator and that other components that could leak, such as TX valves, must be on the engine compartment side of the firewall.

The SAE also evaluated R152a refrigerant, which is more flammable than R1234yf but less flammable than hydrocarbons and has been approved by the United States Environmental Protection Agency as an alternative to R134a – but for use only in new equipment designed specifically for this gas.

“They (SAE) concluded that it (R152a) was unsafe to use, that you would need to add so many safety features,” said Dr Minor.

“For example you would need to add secondary fluid systems so that R152a was not in the condenser at the front of the car in a front-end collision and that it was also not in the evaporator where it could leak into the passenger compartment where an ignition source might be – and hydrocarbons would be even more of a risk than R152a.”

Dr Minor explained that during the commercialisation of R1234yf, investigations were carried out into how it might leak into the passenger compartment, where an ignition source might be and what that that ignition source might be.

“Doing model simulations, modelling leak scenarios, doing real-world ignition testing – you’re working with all the global automotive companies so they have to come to consensus on the test results,” she said.

“It’s a big group and a big organisation that needs to come to consensus that this is acceptable.”

That such extensive work has been done into determining the safety of using hydrocarbon refrigerants in automotive application is doubtful.

Instead, the paying customers of those who choose to use these products are being treated as guinea pigs, while the Australian government continues to turn a blind eye.

R1234yf flammability vs. hydrocarbons

Not all flammable refrigerants are equally flammable. Under ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) there are three flammability classes with ‘1’ being non-flammable (such as R134a) and ‘3’ being highly flammable (like hydrocarbons).

The middle ‘2’ category (moderately flammable) has been subdivided to include a ‘2L’ designation for mildly flammable (almost non-flammable) substances, and is the category into which R1234yf fits.

Compared with the Class 3 hydrocarbon refrigerant propane, which can be ignited by a spark with just just 0.25 millijoules of energy (for example the static electricity jumping from your fingertips to a car door), while the minimum ignition energy required to set R1234yf alight is between 5000 and 10,000mJ.

Once an ignition takes place, propane’s extremely high burning velocity of 46 centimetres per second means the flame travels so fast it causes a very quick pressure rise and a deflagration (essentially an explosion) whereas R1234yf has a burning velocity of only 1.5 centimetres per second, meaning a very weak, unstable flame that is extinguished by any kind of air movement

“This is what gave it its really unique flammability properties,” said Dr Minor.

Finally, R1234yf has a very low heat of combustion, which measures at 10.7 kilojoules per gram compared with 46.3kJ/g for propane.

“When you think about the change of flammability when moving from R134a to R1234yf and comparing it to all the other fluids that are being used (in the engine compartment), this is a very minor change,” said Dr Minor.

“I think the appropriate way to evaluate a refrigerant is to do risk assessment, to understand what the risks are and then to see if you can address it with safety mitigation – and have government oversight to make sure that happens.”

As we all know, that has not happened with hydrocarbon refrigerants in automotive.

“In the US, the EPA has to approve every refrigerant that’s used and they don’t just look at the environmental, they look at the safety aspects and they do not approve hydrocarbon refrigerants for automotive,” Dr Minor added.

If the industry resistance to even mildly flammable R1234yf experienced by Dr Minor’s team and the SAE is anything to go by, any claims that hydrocarbons are suitable as a drop-in retrofit product for existing R12 and R134a systems have zero credibility.

Australia would do well to follow the US EPA’s lead and nip the hydrocarbon problem in the bud before it gets worse than it already is.

How R1234yf got its name

R1234yf is an official ASHRAE designation for the refrigerant, determined by an industry standard that has existed for around 50 years and was devised by DuPont.

- The ‘1’ means it is an olefin – it has a double bond in it, which gives it really low GWP

- The ‘2’ is 1 minus the number of carbons in the molecule

- The ‘3’ is 1 plus the number of hydrogens in the molecule

- The ‘4’ is how many fluorines are on the molecule

- The y and the f indicate where the fluorines and hydrogens are on the molecule.

- CategoriesIn SightGlass

- TagsBarbara Minor, R1234yf, SightGlass News Issue 2