ZF’s by-wire tech could lead to more brake work for auto electricians

- PostedPublished 29 April 2024

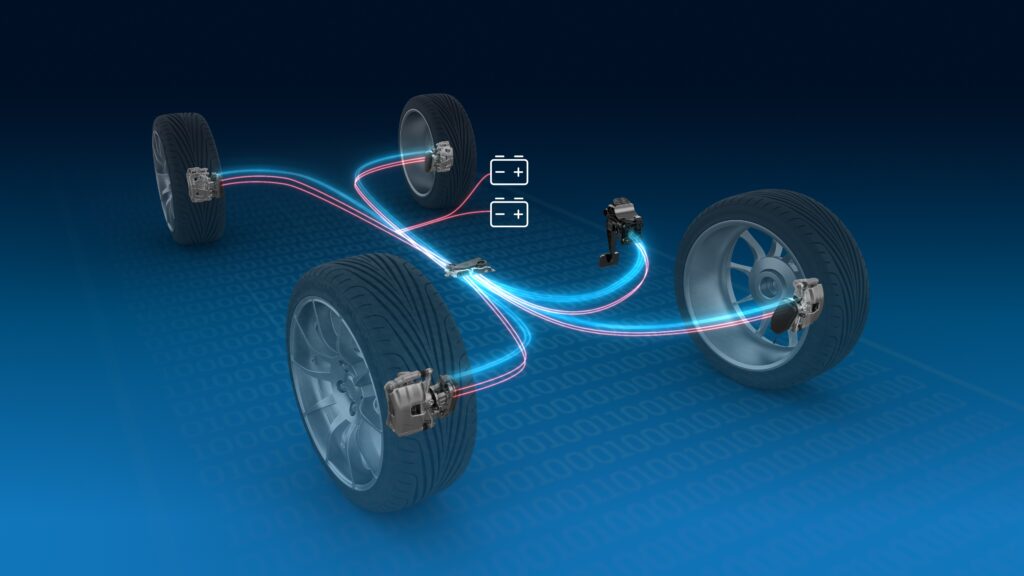

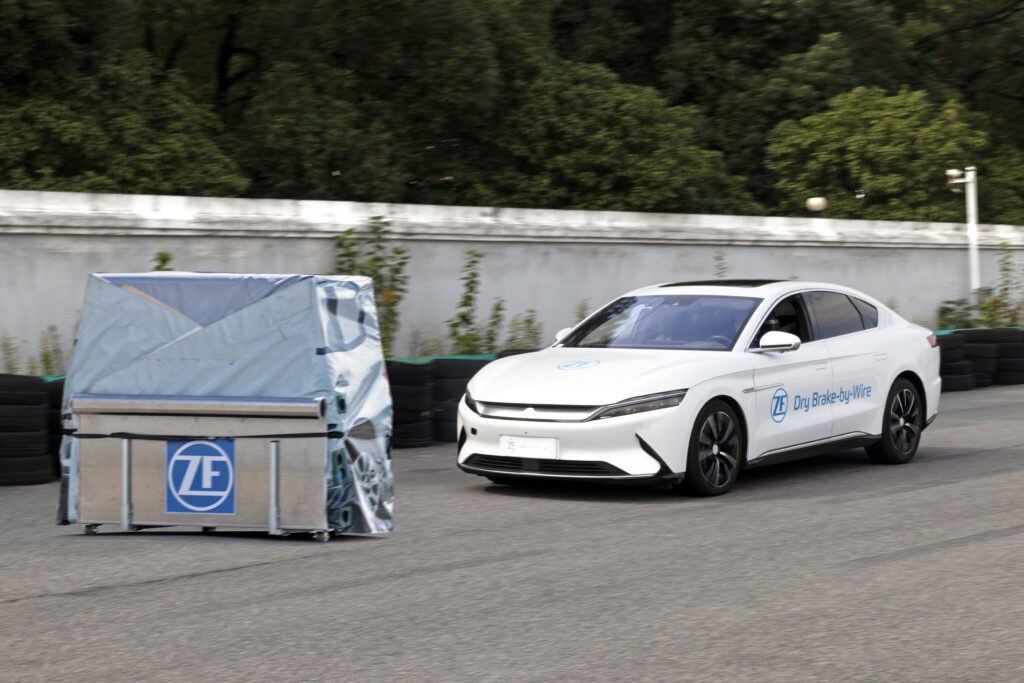

Auto electricians could end up getting more brake work if technology like ZF’s “dry brake-by-wire” system that eliminates the need for a traditional hydraulic setup – and has recently undergone successful testing on a modified BYD Han electrified vehicle – gains mainstream adoption.

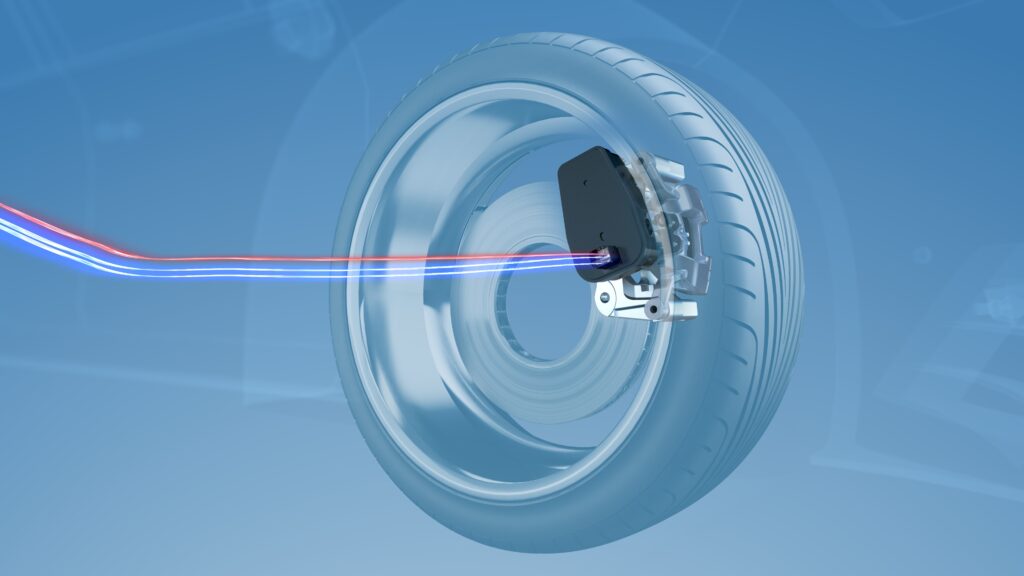

In this cutting-edge system, brake fluid is no longer necessary as braking force is generated by electric motors, claimed to result in significantly shorter braking distances.

For example, during automatic emergency braking from 100 km/h, the ZF system can reduce the stopping distance by up to nine metres compared to conventional brakes, potentially preventing accidents and saving lives.

The system is also said to improve regenerative braking efficiency as well as minimising contact between the brake discs and pads when not in use, reducing both drag and particulate emissions from unnecessary brake pad abrasion, which ZF claims can extend EV range by up to 17 per cent.

In addition to its performance advantages, the dry brake-by-wire system offers cost savings by eliminating the assembly and logistics requirements of hydraulic systems during vehicle production.

Vehicle owners stand to save on brake fluid replacement and it is one less flammable chemical requiring safe disposal by workshops – which will likely gain electrical diagnostic clients when brake issues occur.

The new system is claimed to provide the same pedal feel as hydraulic brakes, while for safety all connections and systems are duplicated, following established practice in aviation industry by-wire systems to guarantee reliable data transmission, processing, and energy supply to the electric motors.

ZF has not yet announced any production vehicle partners for this technology and has no plans to introduce it for heavy vehicles.

- CategoriesIn SightGlass

- Tagsbraking, by wire, electric vehicles, EV, SightGlass News Issue 32