Call for urgent action on EV battery waste stewardship

- PostedPublished 16 October 2023

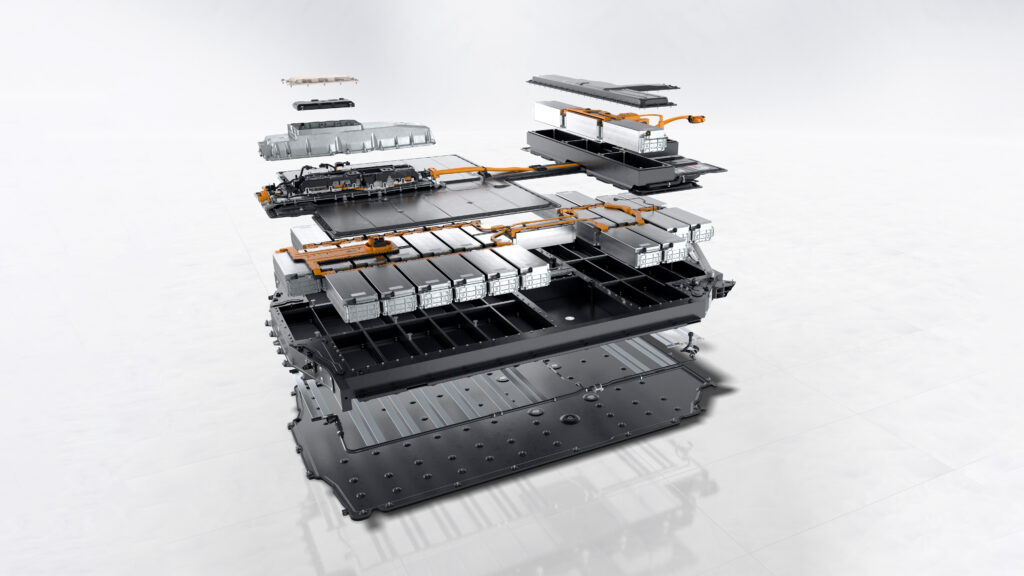

Australia faces a growing challenge with the increasing number of used electric vehicle (EV) batteries entering the waste stream.

If not addressed, EV battery discard could reach 1.6 million tonnes by 2050. Recognising the urgency of the situation, the Federal Government has tasked the Battery Stewardship Council (BSC) with leading industry consultation on EV battery stewardship.

The BSC, established in 2018 and renowned for its successful programmes with smaller batteries, plays a crucial role in ensuring responsible battery management throughout their entire lifecycle, including collection, recycling, and safe disposal.

A recent discussion paper, jointly delivered by the Federal Chamber of Automotive Industries, and the Motor Trades Association of Australia, aims to gather insights and ideas from experts and stakeholders to tackle the issue of future EV battery waste management by creating a tailor-made solution that benefits the entire supply chain while upholding environmental sustainability.

Battery Stewardship Council CEO Libby Chaplin described EV batteries as presenting “increasing risks and opportunities, which the industry is yet to deal with at scale”.

“Investment in battery stewardship and recycling infrastructure is immediately needed to avoid costly solutions in the future and miss out on the financial opportunities offered by recycling used batteries.”

Taking immediate steps to develop the necessary infrastructure for recovering valuable resources from used batteries is crucial. Failing to do so could result in stockpiling and potential safety hazards, including fires as recently experienced near Sydney Airport when a removed EV battery burst into flames and destroyed several nearby vehicles.

This is not only important for minimising environmental impact, but it is also a key component of Australia’s National Electric Vehicle Strategy, which aims to promote the adoption of EVs.

“We probably have enough capacity to deal with the waste stream right now, but … we do need to have processing in place before 2026 or 2027,” said Ms Chaplin.

Establishing an effective stewardship programme and a robust recycling infrastructure, we can create a circular economy for EV batteries in Australia.

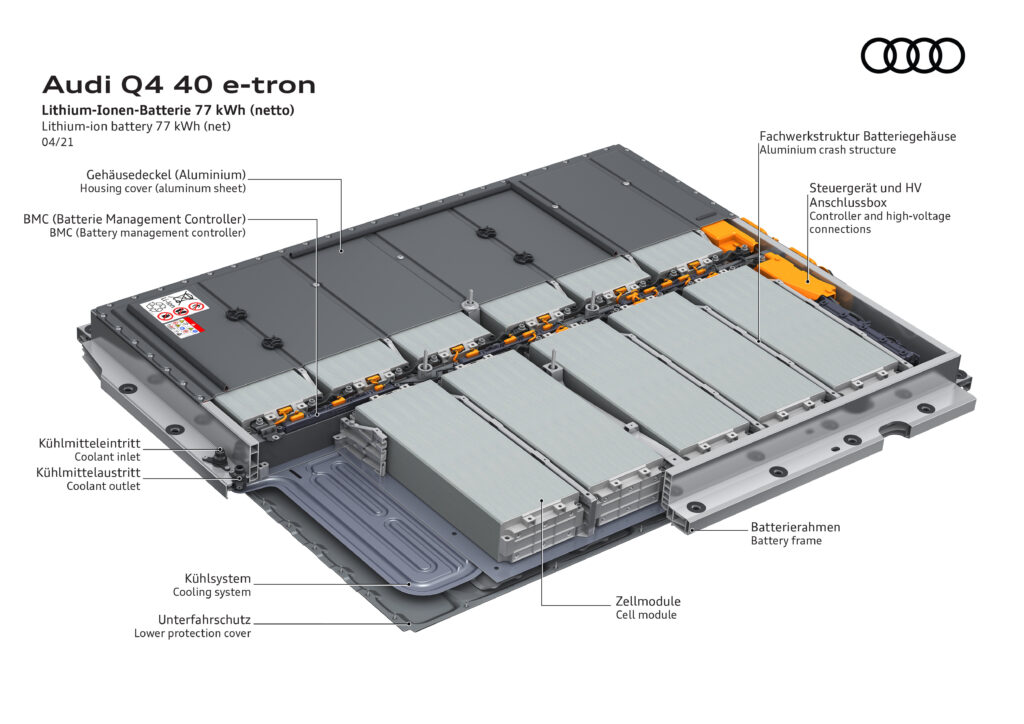

This approach ensures the recovery and reuse of valuable materials from used batteries, reducing the reliance on raw material extraction. Not only does it address the environmental impact of battery waste, but it also contributes to the overall sustainability of the EV industry.

Moreover, the effective management of EV battery waste provides Australia with a unique economic opportunity.

By recycling and reusing materials like lithium, cobalt, and nickel, the country can establish its own supply chain for battery manufacturing, reducing reliance on imports and creating job opportunities. Seizing these prospects can position Australia as a world leader in sustainable battery technologies and support the growth of its green economy.

“The EV industry is facing a golden opportunity to take the lead in designing a scheme that is cost-effective, fit for purpose, and avoids the mistakes and costly fallout of inaction as seen recently by the solar panel industry by prioritising the discussion of end-of-life processes today,” urged Ms Chaplin.

Raising awareness and educating people about sustainability and responsible waste management is crucial. This applies not only to electric vehicle (EV) owners but also to the general public.

As a result, the concept of extended producer responsibility (EPR) is gaining traction in discussions surrounding EV battery waste management.

EPR holds manufacturers accountable for the entire lifespan of the product, including proper waste management. Specific EV battery rules will incentivise manufacturers to design modules that are easier to recycle and invest in waste management facilities. This way, everyone involved in the industry shares the responsibility of handling EV battery waste.

Curtin University professor of sustainability Peter Newman emphasised the urgent need for a recycling plan.

He highlighted that the adoption of zero-emission vehicles is exceeding expectations, and any delay in implementing a plan would result in missing out on a crucial opportunity.

“We need some serious regulation on lithium-ion batteries now … to prevent us from becoming the world’s worst recyclers,” he warned.

- CategoriesIn SightGlass

- Tagsbattery, electric vehicles, EV, SightGlass News Issue 30, stewardship, waste