NZ edges closer to robust, regulated refrigerant stewardship scheme

- PostedPublished 6 May 2024

View from NZ with VASA New Zealand Director Catherine Tocker

A robust refrigerant stewardship scheme for New Zealand, backed by government regulations and aided by the establishment of a domestic end-of-life refrigerant destruction facility is edging closer to reality – but addressing the skilled labour shortage remains a key ingredient to meeting environmental goals.

Uncertainty remains around the timing of the new regulations – which were expected to be announced before the NZ election last October but remain in limbo – so it falls to the voluntary stewardship scheme operated by Cool-Safe since 1993 to continue striving to promote best practices for reducing emissions of ozone-depleting substances and synthetic greenhouse gases.

At the same time, DIY shot cans of refrigerant remain freely available to the public with the only concession to common sense so far being a small label advising purchasers that releasing the refrigerant to atmosphere is an offence under the Climate Change Response Act and to behave responsibly.

SightGlass understands a strong case is being made to the NZ government of the environmental benefits of quashing the availability of these shot cans.

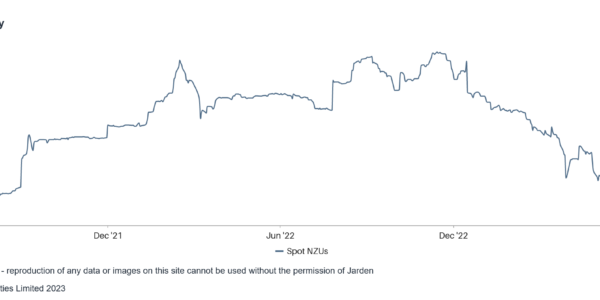

Also in the mix is the establishment of a refrigerant recycling facility in New Zealand by A-Gas that promises to help establish a source of good-as-new refrigerant to the market and help offset the soaring price of high-GWP virgin refrigerants affected by the NZ Emissions Trading Scheme.

While this could help normalise the recovery and collection of used refrigerants, introducing recycling at scale also risks muddying the waters around appropriate refrigerant reuse – with the potential for scammers to offload contaminated product – while potentially extending the lifespan of equipment that might fail and leak instead of being replaced with more energy-efficient technology using low-GWP refrigerants.

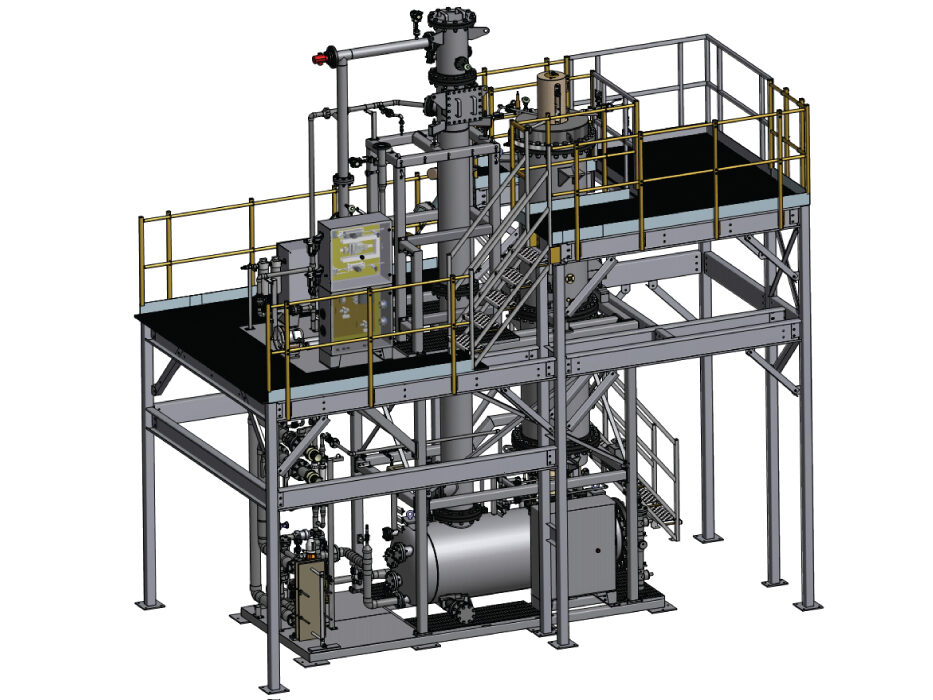

In line with Cool-Safe’s preference for safe destruction over recycling, the organisation is developing a $10 million plasma arc facility at Kawerau in the Bay of Plenty to reduce transport risks and provide local processing.

According to Cool-Safe CEO Janine Brinsdon, the facility is on schedule to become operational late this year, with one of the many benefits being to eliminate the carbon footprint and risks of shipping ISO containers filled with tonnes of end-of-life refrigerant to Australia for destruction.

“You only need to have an accident on a boat and you’ve got an ISO with 22,000kg of refrigerant that the industry has gone to quite some pains to collect and recover, and then suddenly it’s allowed to escape the atmosphere,” said Ms Brinsdon.

She emphasised that Cool-Safe buys mixed end-of-life refrigerant and since increasing its bounty from $15/kg to $25/kg in October 2022 as a way of encouraging NZ business owners to do the right thing – while reducing the friction of refrigerant returns through cylinder swaps and courier collection – Cool-Safe has fed more than $1.1m back into the local HVAC/R sector.

Canadian company PyroGenesis was selected to supply its Steam Plasma Arc Refrigerant Cracking (SPARC) technology for the new plant and is recruiting skilled locals to build, run and maintain the equipment.

On the topic of skilled labour, and consistent with almost everywhere in the world, New Zealand’s refrigerant transition is also impacted by a shortage of qualified technicians to meet demand.

In response, last September Cool-Safe established an independent review of the matter led by facilitator Toby Beaglehole (former CEO of Work Based Learning at New Zealand Institute of Skills and Technology) and formed a strategic leadership forum chaired by Massey University professor Don Cleland with input from Greg Picker (Australian Refrigeration Council and chair and Refrigerants Australia executive director) and representatives from across the HVAC/R sector to ensure all aspects of training needs are understood.

An early outcome of this initiative is that work on a heat pump installer’s micro-credential is already underway to meet a shortfall in the necessary skills for what is a fast-growing area of the industry.

Various forms of training in the market are being assessed for quality and relevance, with those who have proven to complete training that measures up gaining Cool-Safe recognition for the technician and their employer.

As well as upskilling those already in the industry, promoting a career in HVAC/R to attract new entrants is also a priority.

To this end, Cool-Safe marketing and communications coordinator Alex Nebesky is leading recruitment marketing efforts through a working group of technicians and business owners who are sharing their stories about job satisfaction and engagement, as well as the healthy long-term prospects for those working in the HVAC/R sector.

“People I have spoken to have been incredibly happy with their work and want to see more people coming in,” said Mr Nebesky.

A new website and career expos highlight the positives shared by those in the industry, such as the satisfaction of technical problem-solving, variety of work, and cleaner conditions compared to other trades.

In addition to making school leavers aware of their options in the HVAC/R sector, case studies are being developed to attract people from other industries, such as plumbers who had some portable skills in their transition to HVAC/R, as well as those working on high-tech automotive air-conditioning where multiple skillsets are required.

VASA NZ director Catherine Tocker will contribute a case study to the latter.

As the market transitions toward low global warming potential refrigerants, training capacity grows, and regulations are established, New Zealand could become something of a standard-setter for sustainable refrigerant management on the world stage.

Of course, continued collaboration between government, industry, training providers and product stewardship organisations will be important to navigate these changes efficiently while protecting the environment.

About the author

Catherine Tocker is owner of three CoolCar workshops around New Zealand – continues as VASA director for NZ

- CategoriesIn SightGlass

- TagsCatherine Tocker, Cool-Safe, New Zealand, NZ, refrigerant, Refrigerant recovery, regulation, SightGlass News Issue 32