EV battery swapping back on the agenda: But how do thermal management connections work?

- PostedPublished 24 April 2024

EV battery swapping is a process that involves replacing a depleted battery pack with a fully charged unit at a dedicated swapping station, enabling drivers to get back on the road in less than the time it takes to top-up a tank of petrol. The drained batteries are then recharged, typically during off-peak energy times.

Building on the success of this technology in China, battery swap pioneer Nio has officially announced a strategic cooperation agreement with compatriot carmakers Chery and JAC. This collaboration builds upon Nio’s previous partnerships with Geely, Changan, Wenergy, and ATHG.

Together, these companies will establish industry standards for their batteries, which are essential for Nio’s swappable model to work, as the company plans to expand its network of 1000 ‘Power Swap Stations’ in China to 3000, but also potentially enable future models from Volvo, Polestar, Zeekr, Lynk & Co., Lotus, and London Electric Vehicles to use these battery swap stations throughout Europe.

This series of developments corresponds with the recently announced partnership between Ample, a Californian company with 12 locations in San Francisco, and global automotive conglomerate Stellantis which controls Abarth, Alfa Romeo, Chrysler, Citroen, Dodge, DS, Fiat, Jeep, Lancia, Maserati, Opel, Peugeot, Ram and Vauxhall. Additionally, Gogoro, a Taiwanese company with a staggering 12,000 charging locations, has recently disclosed its plans to manufacture e-scooter bikes in India, further expanding its rapidly growing battery swap station network.

Liquids when swapping

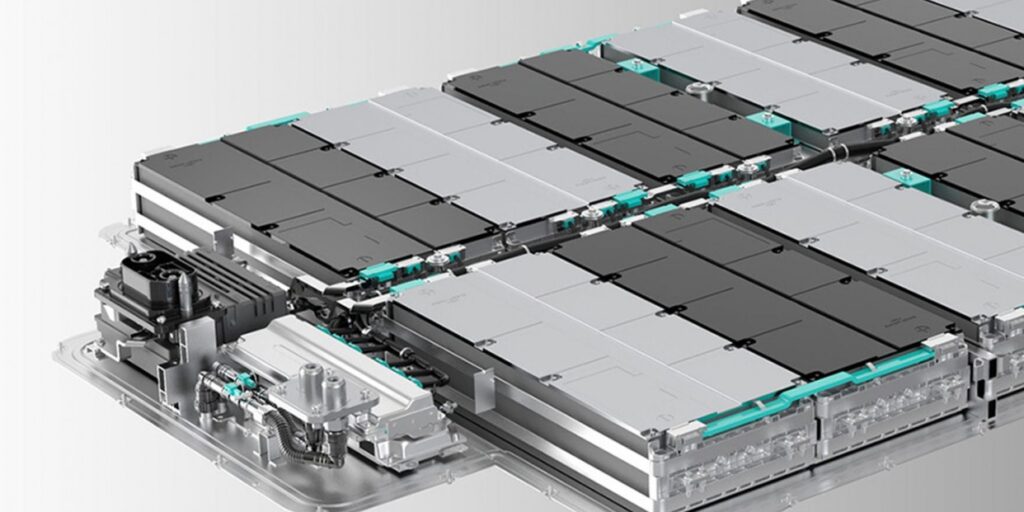

The majority of electric vehicle batteries are cooled with fluids like ethylene glycol, employing a thermal management system that actively reroutes and extracts heat using fans, pumps, and various devices. The liquid circulates through tubes or plates around the battery cells, ensuring no direct contact as it transfers the heat to another location. This could be directly to a radiator, where the heat dissipates into the surrounding environment, or increasingly, a refrigerant circuit for accurate temperature control and efficient harvesting of heat for cabin comfort.

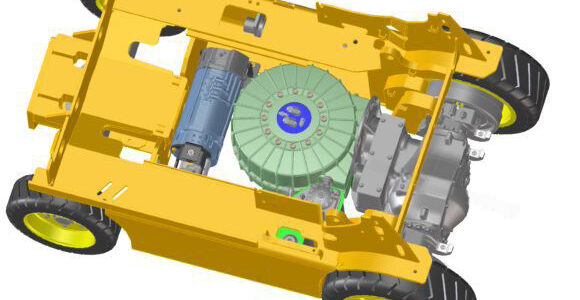

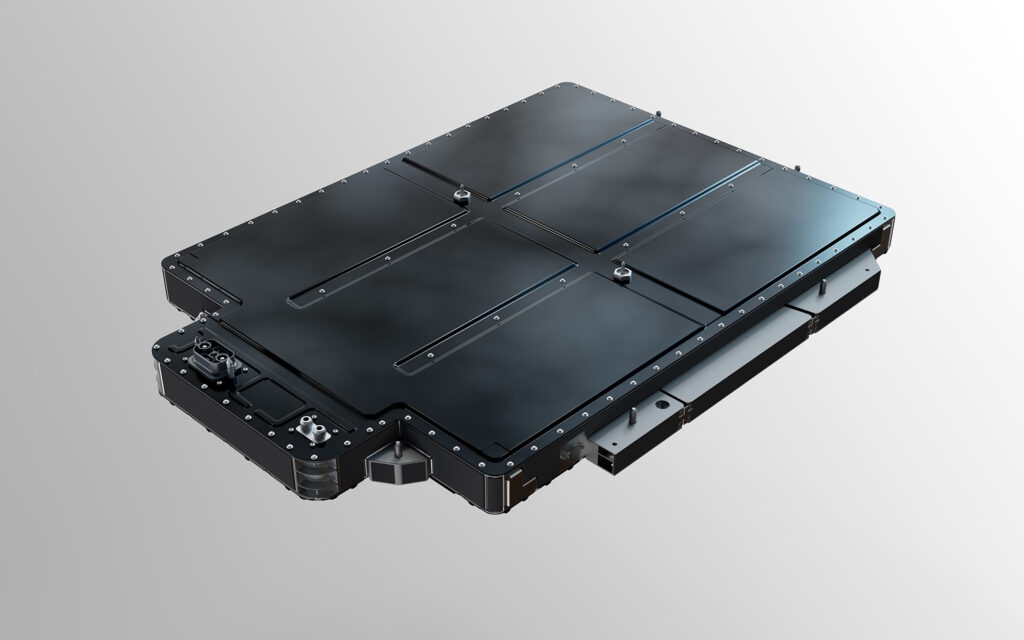

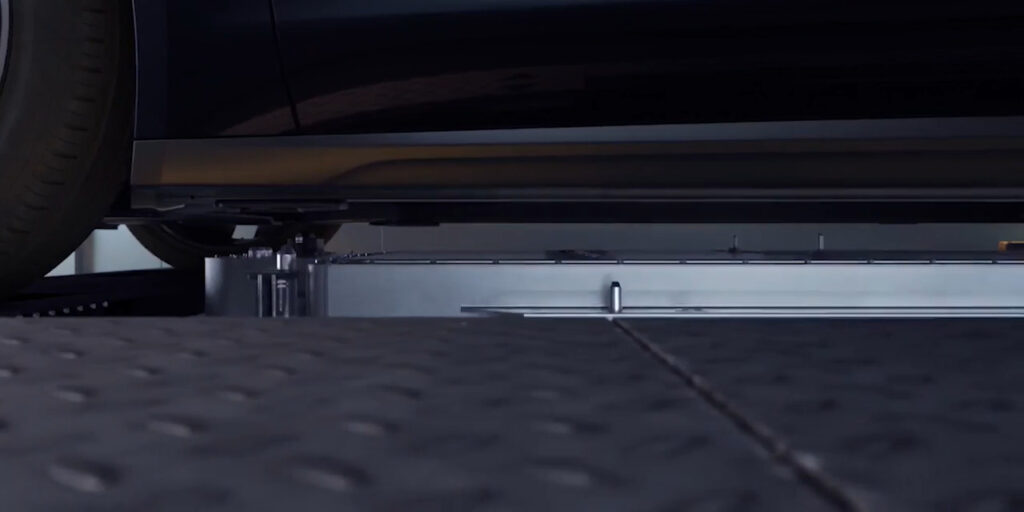

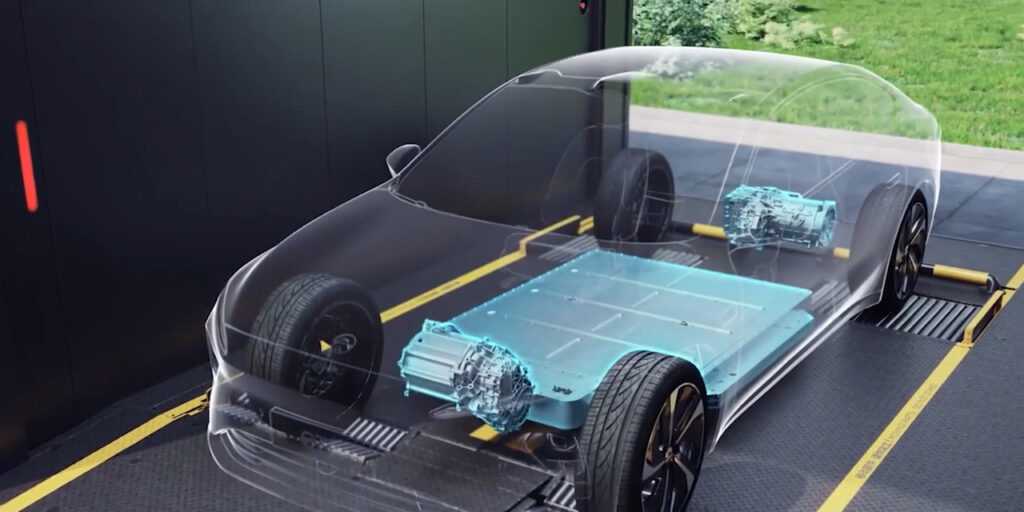

When it comes to robotised EV battery swapping, making a secure physical connection between a vehicle and its power supply terminals is relatively simple; as can be seen from the image opposite there are numerous locating pins around the battery pack and next to the power connector.

Introducing thermal management liquids into the mix can be easily handled when it comes to batteries that have been specifically designed for this purpose.

Here, specialised couplings are used for the battery’s liquid cooling system. These fittings are designed to provide a secure and reliable connection without the need for threading or barbs. Instead, during automated battery fitment, where guides are used to provide accurate alignment, this liquid cooling coupler creates a tight seal that effectively maintains fluid within the cooling circuit and minimises airlocks.

They provide a dripless disconnection during battery removal and are specifically engineered for long-term use where frequent removal is common.

Battery swapping, maintenance, and repair

As EV batteries age, they often generate more heat and undergo energy loss as a result of degradation. Liquid cooling systems, in particular, can face challenges such as leaks, corrosion, and clogging, which place additional stress on the thermal management system. To ensure consistent and efficient battery performance, regular maintenance, monitoring, and timely repairs are essential to maximise battery range and lifespan.

Swappable batteries offer a practical solution to these challenges by making it easier to inspect them while off the vehicle. If a swapped battery is found to be faulty, it can be effortlessly removed from the system and sent for repairs, often without the customer even being aware of the issue. This effectively addresses concerns regarding range degradation and greatly enhances the lifespan and residual values of EVs.

Battery swapping also helps introduce a model where ownership of batteries is transferred to a leasing company where customers can choose to pay monthly fee including battery rental and a level of energy usage.

This not only reduces the upfront cost of an EV but relieves owners of battery repair costs while opening up the possibility of battery upgrades as technology develops, or use of a more energy efficient lightweight small-capacity unit for routine local trips and bigger, heavier packs for planned long-haul drives with fewer stops.

A closer look at Nio

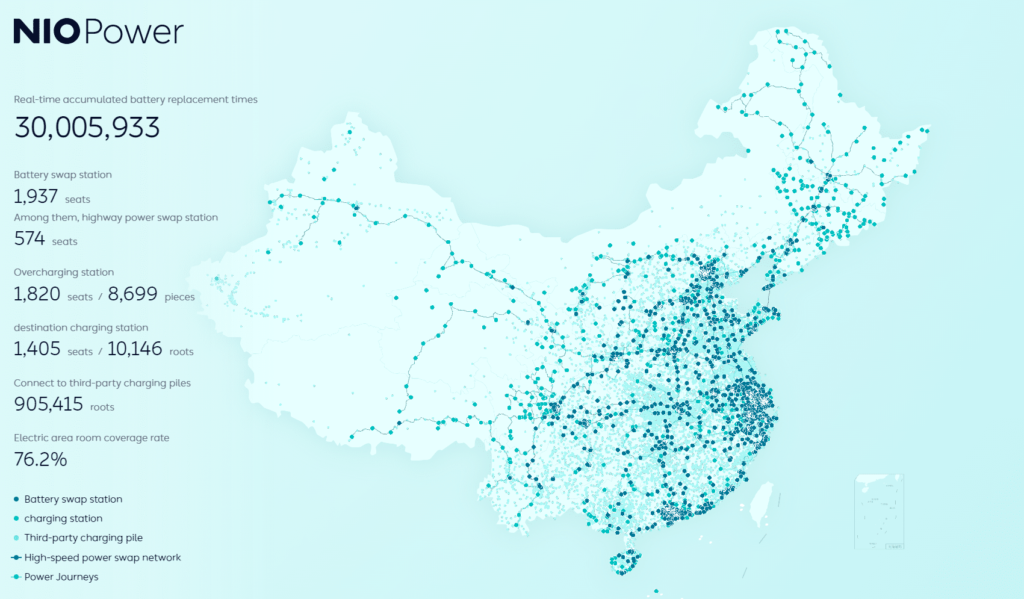

Nio EV models rely heavily on battery swaps, with more than 56 per cent of customers choosing to charge this way, which is particularly advantageous in China where high-density high-rise buildings can make home charging inconvenient or even impossible.

The company’s first Power Swap Station was introduced in 2017, followed by an improved version in 2021. The latest 2.0MWh automated iteration is even faster, taking less than five minutes for a complete battery swap. In fact, Nio Power boss Fei Shen claims that the new station, capable of storing and recharging up to 21 batteries at a time, can handle more than 400 swaps per day, surpassing the record of 171 swaps achieved by the previous version.

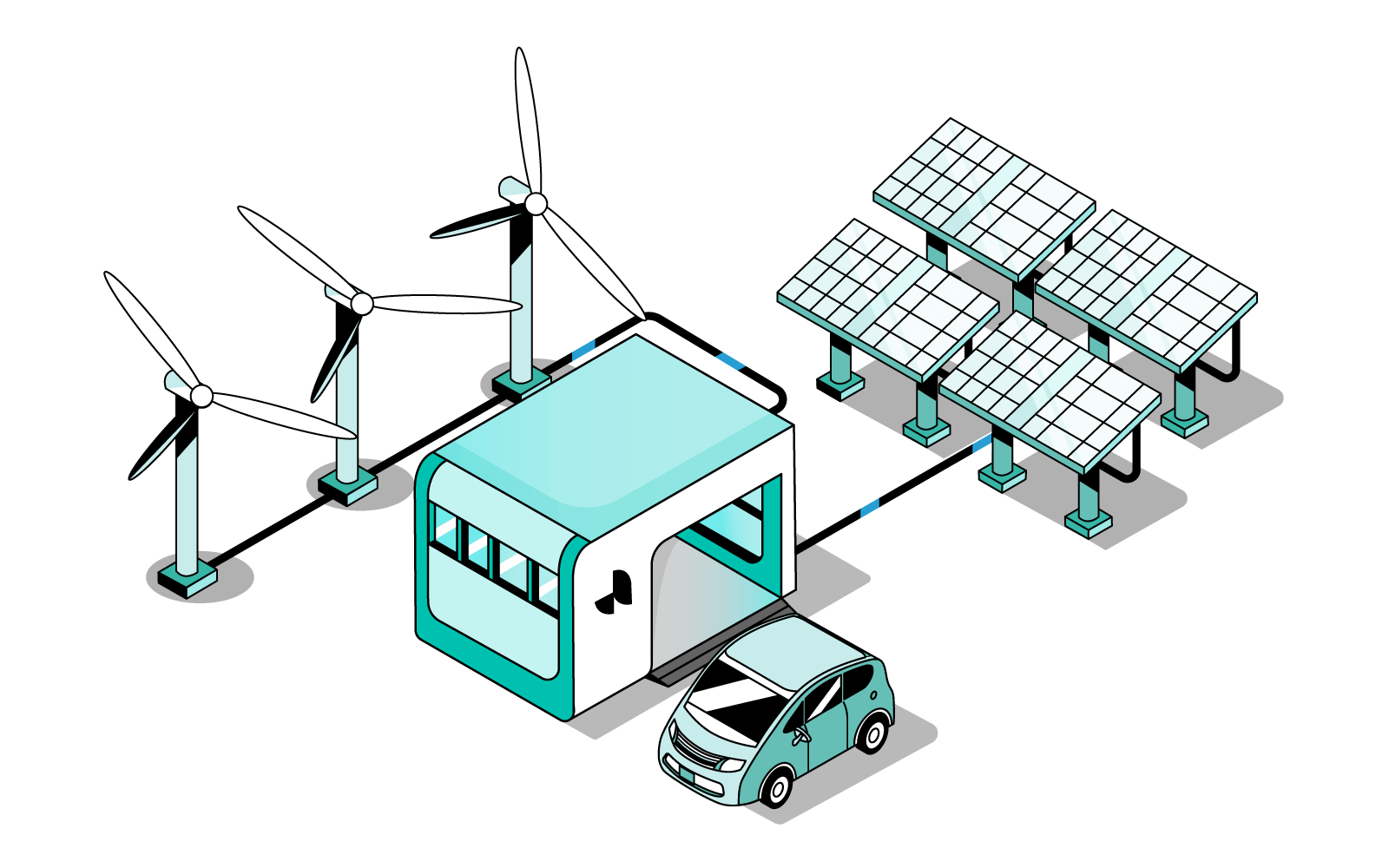

In addition to their convenience and efficiency, Power Swap Stations also play a role in balancing energy grids. They take advantage of low-demand periods to charge the batteries when energy costs are lower, and then, during peak times, the batteries can be used to help balance the grid, more so when taking into account that all Power Swap Stations have conventional chargers too. This means that when there is high demand, the stored batteries can be used to provide energy through these chargers.

Ample’s approach

Another trailblazer in the field of modular robotic drive-through battery swapping technology is Ample, a Californian company that has been committed to developing battery charging solutions for the past seven years. Ample’s trial with Stellantis aims to enhance its infrastructure in Madrid by constructing nine additional charging stations, which will complement the existing four. The purpose of these stations is to test Ample’s technology using 100 Fiat 500es within the Stellantis-owned Free2move car sharing service.

One advantage of Ample’s modular battery swapping approach is that it does not require car, van, or truck manufacturers to modify or standardise the design of their vehicles. Their non-proprietary modular batteries are designed to fit in the same space as the original batteries, and while there are still some interfaces between the battery and the car that may require modifications, such as voltage cables or cooling lines, this is relatively simple to handle, though the drawback of being locked to a sole supplier may be less favourable for some, particularly with regards to infrastructure availability.

Other battery swapping models

Founded in 2011, Gogoro sells electric scooters that come with access to a network of battery-swapping stations. Instead of charging their scooters, owners can simply drive up to a self-service GoStation and exchange their two 9-kg high-capacity solid-state battery packs for fully charged ones, offering ranges of up to 170 km. The system’s popularity is soaring to the point where it is expected to soon surpass the number of petrol stations in Taiwan.

Recently, Gogoro has begun manufacturing electric scooters in India, where it plans to establish around 100 battery swap stations by mid-2024 and has committed A$2.2 billion of investment in the western Maharashtra state.

The company expects half of its e-scooter sales to come from delivery fleets and bike taxis within five years and plans to export 20% of its Indian production to neighbouring countries.

Interestingly, Gogoro batteries use “paraffin wax” to regulate battery pack temperature in their electric scooters; this undergoes a phase change process to absorb and release thermal energy, preventing temperature spikes by absorbing excess heat when generated and then releasing it when the surroundings are cooler, helping to maintain battery performance.

The future of battery swapping

Battery swapping, once abandoned by Tesla a decade ago and previously attempted by Renault with their Fluence model in a joint venture with Better Place prior to the Israeli startup’s bankruptcy in 2013, has been regaining traction.

This renewed interest is evidenced by Nio’s impressive accomplishment of surpassing 30 million battery swaps in China last year.

However, despite improvements in charging rates, proponents argue that battery swapping not only enables faster charging for long journeys but also has the potential to lower costs.

By separating batteries from vehicles, the purchase price of EVs can be reduced, making them more affordable and accessible to a wider range of consumers, especially in areas where charger accessibility is limited.

For battery swapping to become more viable, it is widely accepted that collaboration among brands is essential. This involves sharing swap stations and implementing standardised battery formats that can be used across different vehicle types, as per Nio’s approach.

Such participation would streamline the process, foster the growth and acceptance of battery swapping technology, and enable companies like Ample to participate more easily in its expansion.

Nevertheless, the question remains: Are we prepared for this level of collaboration, and will governments, like those in China, facilitate closer cooperation among automakers?

Time will tell, but it seems the technology is well proven and could solve a lot of barriers to adoption.

- CategoriesIn SightGlass

- Tagsbattery swapping, electric vehicles, EV, SightGlass News Issue 32, thermal management